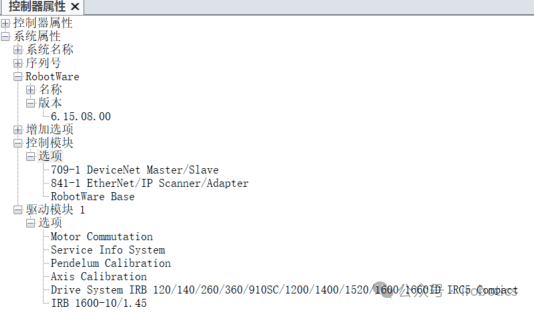

Over the weekend, I was assisting a client in using the IRC5 compact cabinet to communicate with the Xinjie XDH series PLC as a slave (Adapter) while the PLC acts as the master (Scanner) via EtherNet/IP. During the technical support process, I recorded some steps and issues to share, to avoid pitfalls.The client’s machine is a 1600-10 equipped with the second-generation IRC5 compact cabinet.

The configuration of the robot’s EtherNet/IP is actually quite simple:

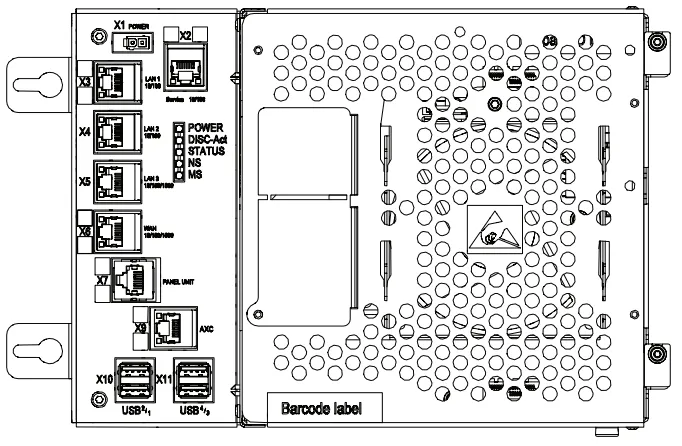

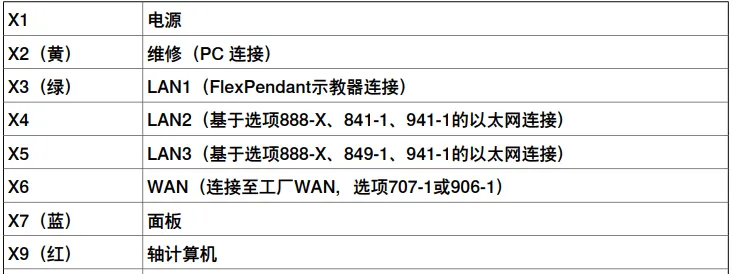

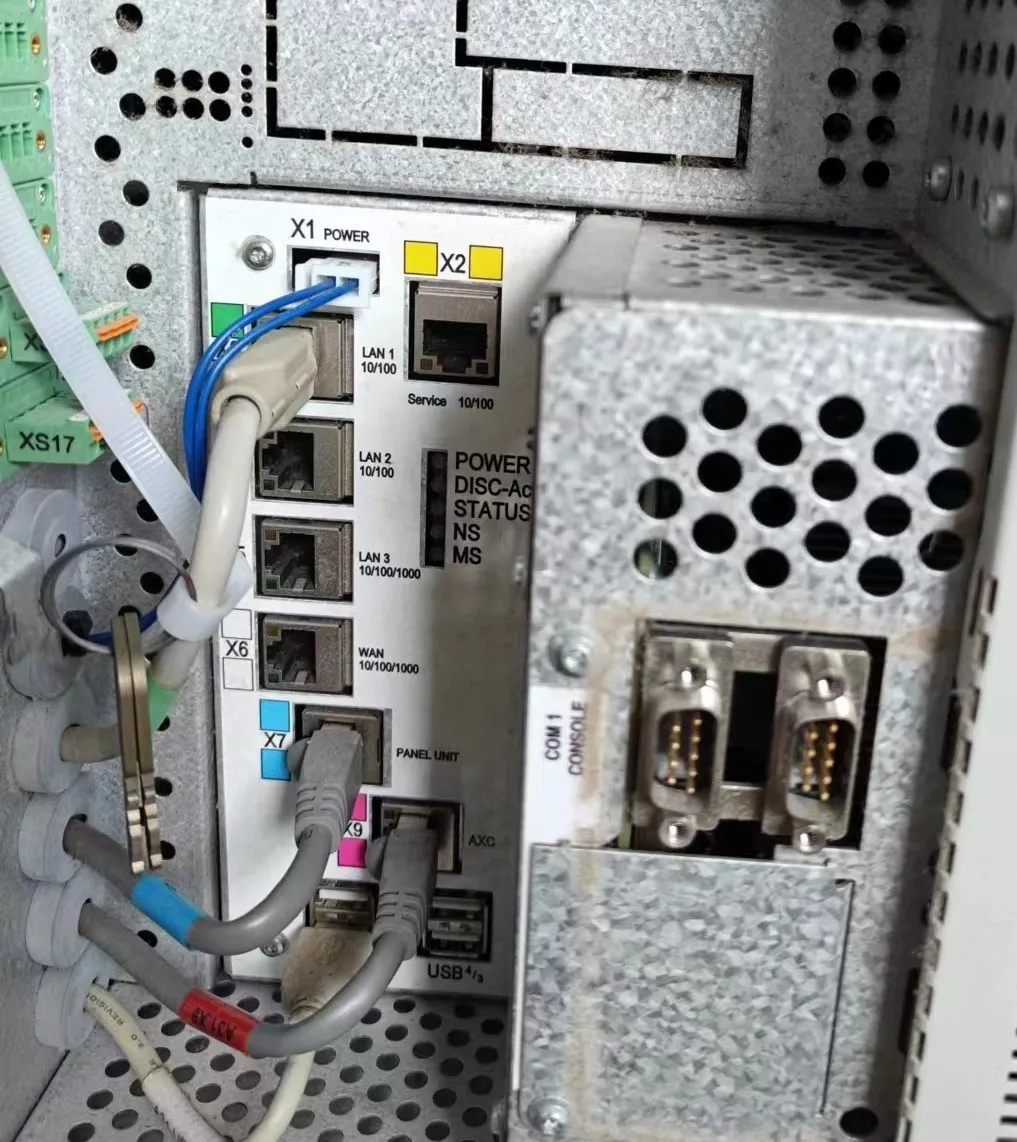

1. Determine which network port to use

For an introduction to the IRC5 network ports, see the article:

Introduction to ABB IRC5 Host Network Ports – 01

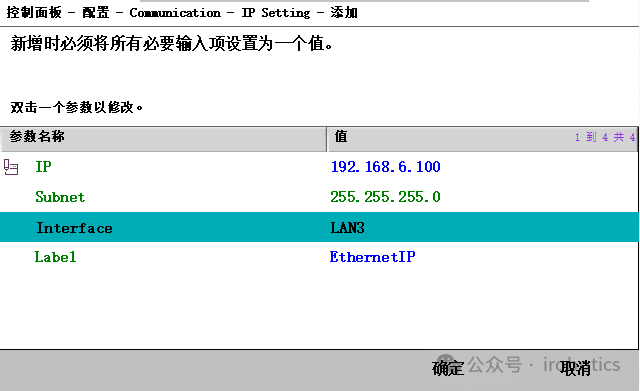

This time, I specifically tested LAN2, LAN3, and WAN, all of which communicated smoothly. Below, I will describe the settings on the robot side using LAN3 as an example.2. Robot IP Address Configuration

This time, I specifically tested LAN2, LAN3, and WAN, all of which communicated smoothly. Below, I will describe the settings on the robot side using LAN3 as an example.2. Robot IP Address Configuration

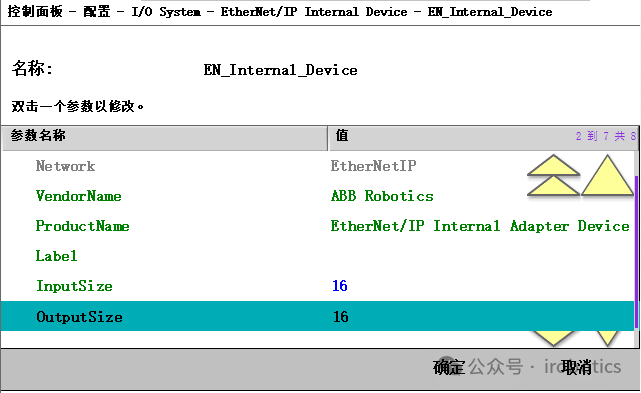

3. Configuration of Robot Input and Output Byte Sizes

The EIP configuration steps for the Xinjie PLC are as follows:

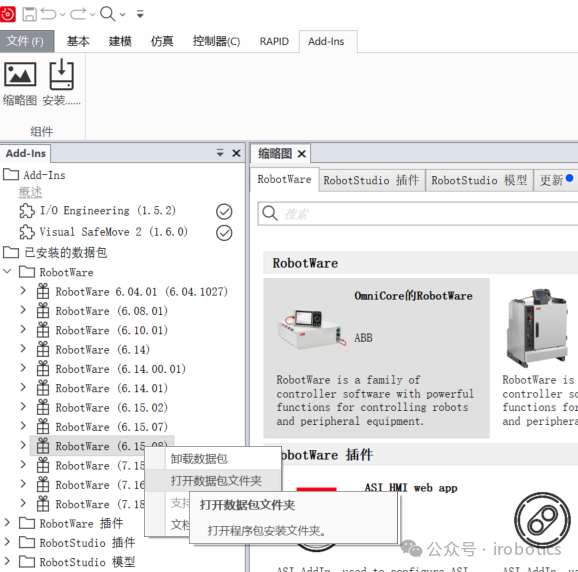

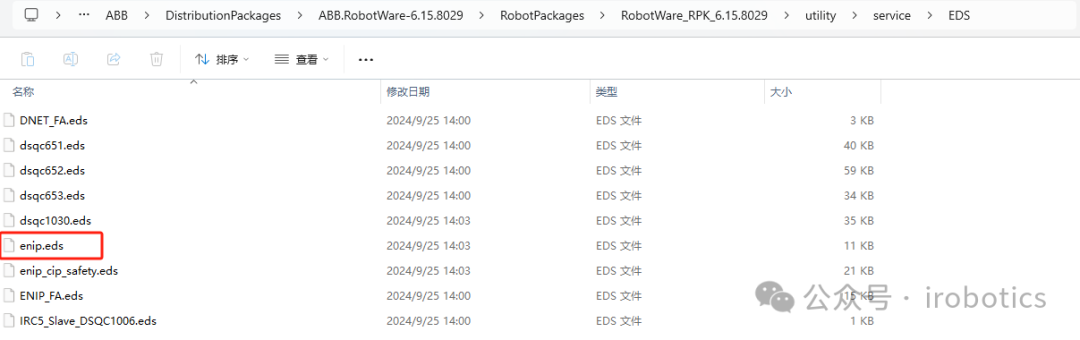

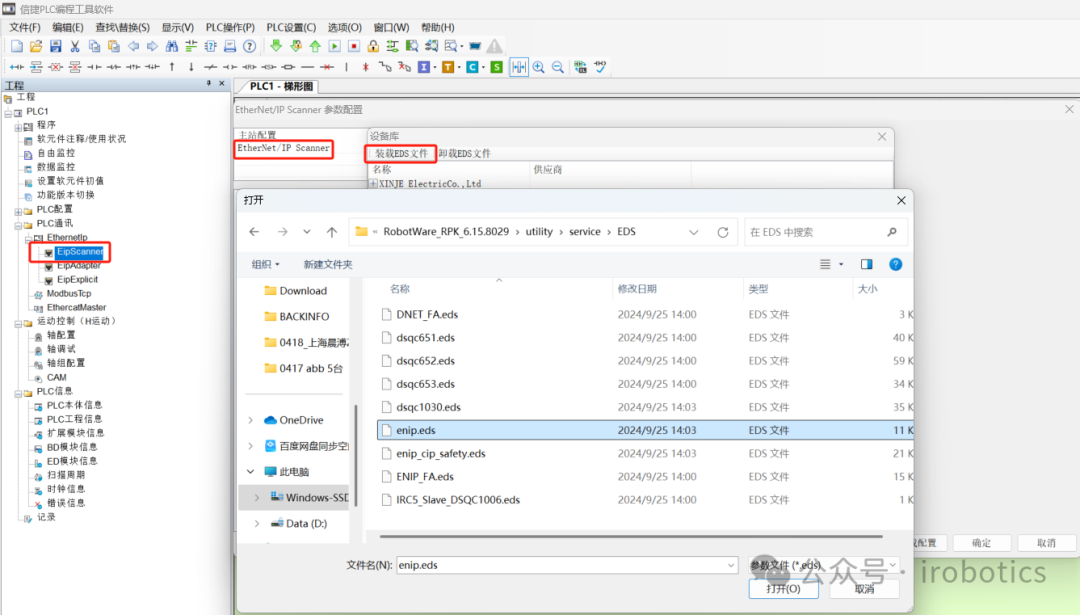

1. Install the ABB Robot’s ESD file

Obtain the robot’s ESD file:

The path is as follows:

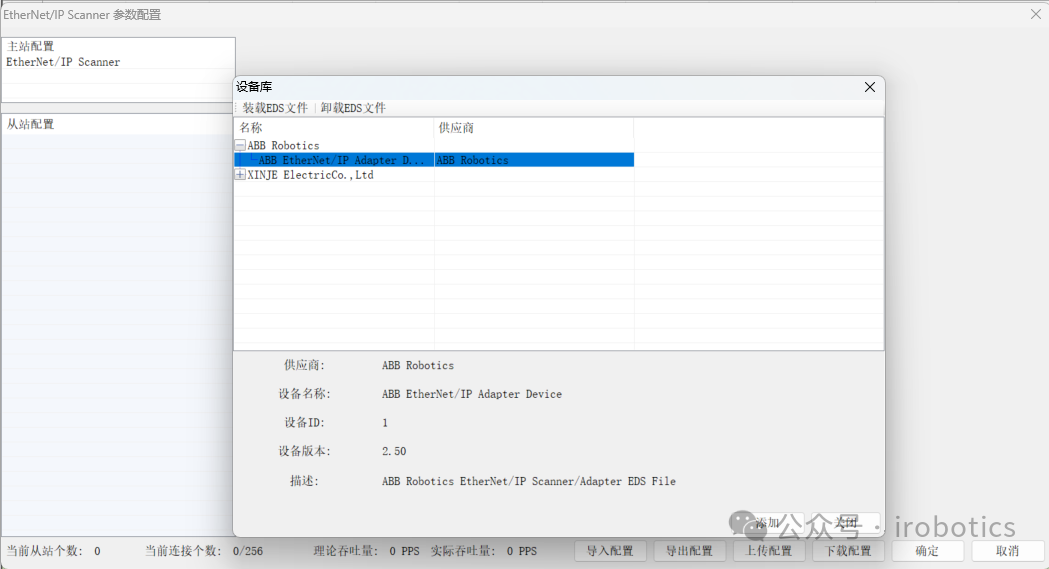

Install the robot’s ESD file:

Install the robot’s ESD file: Add

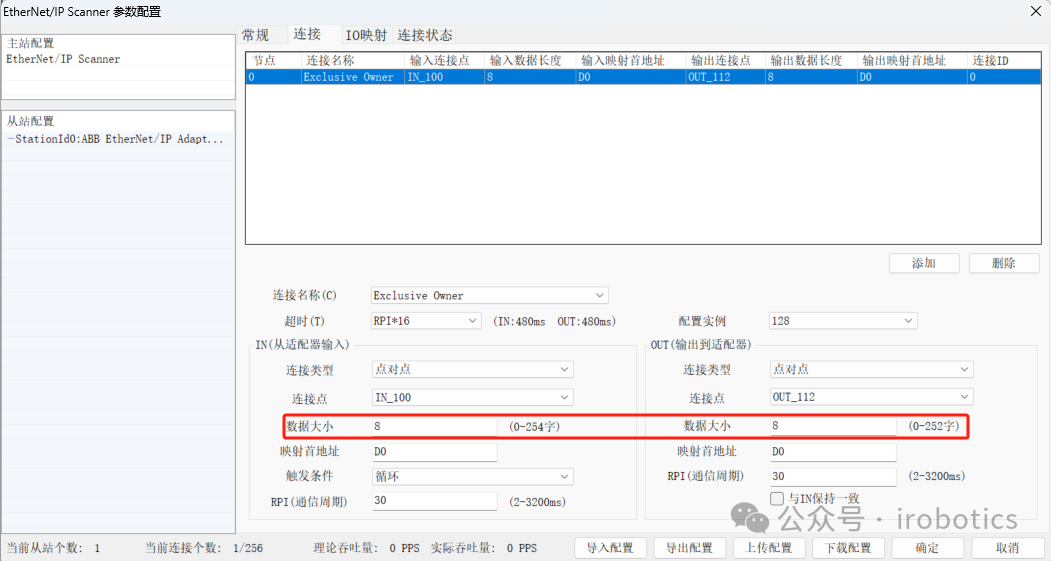

Add configuration, keeping everything default except for the IP address and input/output sizes.The IP address should match that of the robot side.

configuration, keeping everything default except for the IP address and input/output sizes.The IP address should match that of the robot side. The input/output sizes should match those on the robot side.

The input/output sizes should match those on the robot side. It is worth noting that on the PLC side, the size is in words (16 bits), while on the robot side, it is in bytes (8 bits).This discrepancy in input/output sizes caused communication failures and alarms.Just pay attention to the high and low bits later.Then download the configuration and check the connection status to see if the connection is successful.

It is worth noting that on the PLC side, the size is in words (16 bits), while on the robot side, it is in bytes (8 bits).This discrepancy in input/output sizes caused communication failures and alarms.Just pay attention to the high and low bits later.Then download the configuration and check the connection status to see if the connection is successful. Alright, that’s it for today.

Alright, that’s it for today.

This public account records some experiences I have accumulated in my work to achieve the goal of learning while recording, allowing clients who encounter similar problems to avoid detours. I aspire to become a tool for reference to grow together with clients. Welcome partners to share any problems encountered at work or insights for discussion, recording, and sharing to make the application of robots simpler, ensuring that there are no difficult-to-use robots. Learning by doing! Learning from practice and applying what I have learned. Undertaking automation solution simulation, verifying robot reachability and interference with surrounding equipment, and pre-planning paths. If you have any needs, please leave a message in the background.Thank you for your attention!