IntroductionIn the workshop, PLCs act like the “nerve endings” of the factory, while the MES system serves as the “brain”. To enable efficient communication between them, the OPC UA protocol is the most reliable “translator”. Today, we will guide you step-by-step on how to successfully connect PLCs to MES systems via OPC UA, complete with a pitfall guide and practical case studies, so you can get hands-on after reading!

1. Basic Concepts: The “Workplace Relationship” between OPC UA and MES

1.1 What is OPC UA?

- Simple Analogy: OPC UA is like the “international translator” in a factory, capable of translating the “dialects” of different brand devices (PLCs, sensors, etc.) into a standard language.

- Technical Essence: A cross-platform, highly secure industrial communication protocol that supports encrypted transmission and complex data structures, it is the core communication standard of Industry 4.0.

- Core Advantages: No need for industrial computers, does not rely on operating systems, and can even run “bare” (without an OS).

1.2 Responsibilities of the MES System

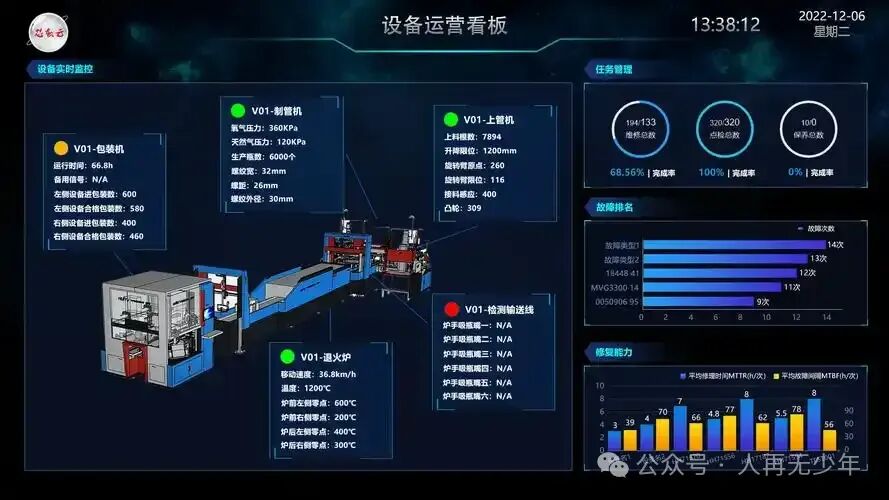

- Functional Positioning: MES is the “production commander” of the factory, responsible for monitoring production progress, quality control, and equipment status. Its “eyes” are the data acquisition systems.

- Pain Points: Traditional MES collects data via OPC Classic, but is limited by the Windows platform and security, making OPC UA a better choice.

1.3 Why Use OPC UA for Integration?

- Safe and Reliable: Data is transmitted securely, capable of penetrating firewalls, avoiding the risks of “bare” operation.

- Cost-Effective: Embedded gateway solutions are 90% cheaper than traditional industrial computers + software licenses.

- Universal Compatibility: Supports mainstream PLCs like Siemens and Mitsubishi, and can also connect to older devices like Modbus.

2. Hardware Connection: Choosing the Right “Courier” is Key

2.1 Comparison of Hardware Solutions

| Solution | Cost | Stability | Applicable Scenarios |

|---|---|---|---|

| Industrial Computer + OPC UA Software | High | Average | Laboratory Environment |

| Embedded Gateway (e.g., BL110UA) | Low | High | Industrial Site (High Temperature, Vibration) |

| PLC Supporting OPC UA (e.g., S7-1200) | Medium to High | High | New Equipment |

Pitfall Guide: For older workshops, prioritize gateway solutions; for new projects, directly use PLCs that support OPC UA.

2.2 Wiring Practice (Taking BL110UA as an Example)

PLC (RS485) → Gateway (COM1)

Gateway (Ethernet) → Switch → MES Server

Key Notes:

- In industrial environments, always use shielded twisted pairs to prevent electromagnetic interference.

- It is recommended to power the gateway independently to avoid PLC power fluctuations affecting it.

3. Software Configuration: Getting Data “Running”

3.1 PLC Settings (Taking Siemens S7-1200 as an Example)

// Ladder Diagram Segment: Trigger Data Acquisition Signal

Network 1

| "Production Complete" Signal |----(SET)--"Collectible" Flag

| Timer T1 (30s) |----(RESET)-"Collectible" Flag

Code Comment: When production is complete, set the flag; if MES does not respond within 30 seconds, it automatically resets to prevent data accumulation.

3.2 Gateway Parameter Configuration

- Communication Protocol: Select the driver corresponding to the PLC brand (e.g., for S7-1200, choose S7 protocol).

- Data Mapping: Map the PLC’s DB block address to OPC UA nodes (e.g., DB1.DBW0→ns=2;s=Temperature).

- Subscription Interval: Set to 100ms (in the case study, a 1-second interval caused data loss).

Debugging Tips: Use UAExpert software to test if nodes are readable; ensure connectivity before integrating with MES!

4. Classic Case Study: The Comeback of an Automotive Factory

4.1 Project Background

A certain automotive parts factory’s S7-1500 PLC frequently “lost connection” with MES, resulting in over 30 data losses daily, causing the workshop manager to be frantic.

4.2 Problem Identification

- Traditional Thinking: MES and PLC programs blame each other.

- Ultimate Weapon: Use PLC-Recorder to capture packets simultaneously, discovering that the OPC UA subscription interval was set to 1 second, causing MES response timeouts.

4.3 Solution

Switched to the Softing uaGate SI gateway:

- Plug and Play: Dual network ports for isolation, physically separating IT/OT networks.

- No Programming Required: Directly read optimized data blocks without modifying the PLC program.

- Interference Resistant: Passed environmental tests from -40℃ to 70℃, with surge voltage resistance of 4kV.

Results: Over 300 gateways deployed globally, with data loss rate reduced to 0!

5. Common Issues “Emergency Room”

5.1 Data Intermittent?

- Symptoms: MES displays intermittent data.

- Diagnosis: Check subscription interval (recommended ≤100ms) and firewall rules.

- Prescription: Adjust in the OPC UA server parameters

<span>MinPublishingInterval</span>.

5.2 Connection Timeout?

- Possible Causes: Network jitter or high PLC load.

- Recommended Solution: Enable “store and forward” function in the gateway to temporarily store data locally during network outages.

5.3 Frequent Security Alerts?

- High-Risk Operations: Using anonymous access or SHA-1 encryption.

- Correct Approach:

- Enable

<span>SignAndEncrypt</span>security mode. - Adopt

<span>Basic256Sha256</span>encryption policy. - Disable automatic trust for self-signed certificates.

6. Security Precautions (Lessons Learned!)

- Certificate Management: Private keys must be stored securely, and revocation lists should be updated regularly.

- Access Control: Anonymous accounts should only have read-only permissions.

- Physical Protection: Install tamper-proof enclosures for gateways to prevent manual disconnection.

7. Practical Recommendations

- Beginners Start: Begin with the Baile BL110UA + Mitsubishi FX3U combination, costing less than 500 yuan.

- Essential Debugging Tools: Wireshark packet capture tool + UAExpert testing client.

- Advanced Learning: Study the OPC UA Pub/Sub model to lay the groundwork for IoT expansion.

Ultimate Advice: First run the entire process on a small production line before rolling it out to the entire factory!

Image Suggestions

- Image 1: Physical connection diagram of the OPC UA gateway in the workshop (labeling network ports and power supply).

- Image 2: Node browsing interface in UAExpert (highlighting key variables like temperature and pressure).

- Image 3: Data flow timing diagram (showing millisecond-level response from PLC → gateway → MES).

Copyright Notice: This article is original by “Ren Zai Wu Shao Nian”, with case references from Baile Technology, Softing, and other manufacturers’ public materials. Please indicate the source when reprinting.