A common understanding in the automotive industry is that future automotive software will dominate industry competition, hardware will tend to unify, and software will become an important aspect for automakers to build differentiated products, which is known as “software-defined vehicles”.

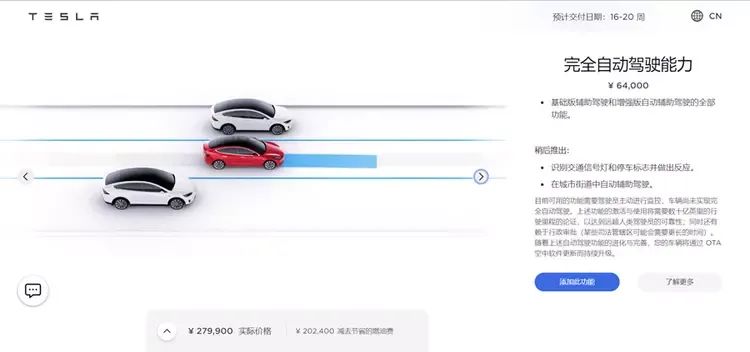

Currently, “software-defined vehicles” have become an unavoidable focal point for automotive manufacturers. In 2016, Tesla launched the “hardware pre-installation + paid software unlocking” model, marking the entry of automotive paid software models into the public’s vision. The concept of “software-defined vehicles” was formally proposed by Baidu’s Senior Vice President and General Manager of the Autonomous Driving Division, Wang Jin, in 2016, which involves using the hardware in vehicles as a foundational platform to achieve corresponding functions and performance through software configuration and deployment.

Image source: Internet

The four disruptive trends in the automotive industry—intelligence, connectivity, electrification, and sharing—heavily rely on advanced software. Whether in terms of functionality or architecture, the complexity of automotive software is increasing, while the efficiency of development work has not kept pace. As the proportion of software in vehicles increases, cars are gradually moving from information silos to interconnected systems, with “data-driven” and “software-defined” becoming new characteristics of vehicle integration applications, posing new challenges for automotive software development.

In automotive software development, the software development process is the core of software engineering, as it provides a framework for software development practices and ensures rigor. Traditional automotive electronics suppliers and OEMs mainly adopt the V-model in the embedded systems development phase, which, along with the AUTOSAR framework specifications and other architecture methods driven by non-functional requirements, constitutes the methodology for traditional automotive electronic systems development.

The specific steps of the V-model development process are as follows:

1

Requirement definition and function design. Graphical modeling is performed in environments like MATLAB/Simulink based on the system’s functional requirements to establish controller models and controlled object models, followed by offline simulation and analysis.

2

Rapid control prototyping. A real-time simulation model is established and downloaded to the prototype system, connected to the actual controlled object for testing, to verify the feasibility of the control system’s hardware and software solutions.

3

Target code generation. Product code generation software is used to convert the model and automatically generate product code. This process can optimize the code for specific ECUs.

4

Hardware-in-the-loop. Real controllers, controlled objects, or parts of the system operating environment are simulated using actual objects and simulation models to conduct system simulation testing.

5

Testing and calibration. This is used for calibrating and testing ECUs during system integration, making necessary parameter adjustments under convenient conditions.

However, the V-model process is not only cumbersome but also increasingly difficult to adapt to the rapidly changing market demands, especially for the increasingly complex information systems related to human-machine interaction and autonomous driving. To meet market challenges, more and more software teams are now inclined to use agile frameworks for software development, aiming to ensure software security and completeness while enhancing collaboration among cross-functional teams and shortening software iteration times.

The four core values of agile development are:

1

Individuals and interactions over processes and tools. Agile development emphasizes stimulating the initiative of individuals, trusting each member, empowering them fully, and leveraging their potential, valuing interactions among team members, and encouraging face-to-face communication even in the face of bad news. Agile development motivates every member of the team to work with the passion of a startup.

2

Working software over comprehensive documentation. In agile development, since features are implemented one by one, the requirements for documentation are less; at the same time, it ensures that the software is functional in each implemented part. In agile development, each feature independently undergoes several stages from requirements to design to integration and testing, ensuring that it is functional and thoroughly tested, allowing at least some promised features to be delivered to users with high quality.

3

Customer collaboration over contract negotiation. This emphasizes communication and collaboration with customers. In agile development, the development team should continuously seek feedback from customers about the completed parts, which may help customers gradually discover and clarify their real needs. Customer needs and priorities may change, and the ultimate goal is to satisfy customers and achieve the desired outcomes, rather than merely fulfilling a contract.

4

The essence of agile development is iteration. Iteration refers to breaking down a complex and long-term development task into many small tasks that can be completed in short cycles. Each cycle is an iterative process, and each iteration can produce or develop a deliverable software product. First, complete the most basic requirements, ensure that there is working code delivered to users, and then optimize and improve it iteratively when there are extra resources, ultimately achieving a refined result.

The V-model development process emphasizes complete verification, which generally remains unchanged after product delivery and does not accept user feedback for improvements or upgrades. In contrast, over-the-air (OTA) upgrade technology emphasizes accepting feedback and upgrading updates to form a closed loop that continuously improves user experience, allowing online fixes for system vulnerabilities, reducing the probability of recalls due to failures, providing timely after-sales service, and accelerating personalized functional updates.

OTA was first applied in the communication field, enabling remote management of SIM card data and applications through mobile communication’s air interface. With OTA functionality, various upgrade requirements such as differential upgrades, firmware upgrades, and system upgrades can be completed. OTA technology is relatively mature and widely used in software upgrades for mobile terminals such as smartphones.

The OTA system includes three parts: mobile terminal, mobile network, and OTA server:

1

The mobile terminal is used to receive and execute service requests as needed.

2

The OTA server includes gateway devices and application servers. Gateway devices connect the mobile network and the OTA application server, completing the format conversion of information, while the application server is responsible for sending service requests (such as activation, deactivation, upload, modification, etc.).

3

The mobile network includes SMS centers, GSM/GPRS networks, etc., responsible for sending service request information to the mobile terminal via short messages, GPRS, etc.

The OTA upgrade process is as follows:

1

Management of vehicle models, vehicles, software, and version releases is conducted in the cloud.

2

The vehicle initiates a check with the cloud to see if there is an updated software available.

3

The vehicle downloads the available upgrade package.

4

The vehicle prepares for the installation of the new software, including condition verification, pre-installation prompts, and interactions.

5

The vehicle begins the installation of the new software, where the upgrade main control program transmits the upgrade package to each electronic component.

In recent years, with the development of the Internet of Vehicles, the application of OTA in cars has gradually increased, and automakers are paying more attention to this technology. After 2019, many domestic and foreign automakers, such as SAIC, GAC, FAW, Changan, Toyota, Volkswagen, and BMW, have established software departments (companies) to develop smart driving digital businesses. Since 2020, several new car manufacturers have launched new smart electric vehicles, and OTA technology has been widely applied in upgrading vehicle systems on new models.

In conclusion, with the development of intelligent connectivity and autonomous driving technology, “software-defined vehicles” have become the future trend. The criteria for determining the quality of future vehicles are no longer limited to leather seats, power performance, or fuel consumption; they also include whether the vehicle’s software can keep pace with the times, continuously providing users with a more thoughtful intelligent experience. As the optimal way to achieve this goal, OTA upgrade technology has gradually become a standard feature of smart connected vehicles, continuously enhancing the potential value of cars.

This content is excerpted from the new book by Machine Industry Press“Automotive Electronics and Software Architecture”

Editor-in-Chief: Wei Xuezhe

Planned Editors: He Shijuan, Wang Jie

Publisher: Mechanical Industry Press

ISBN: 978-7-111-72778-1

Price: ¥69.90

Mechanical Industry Press Automotive Branch

Group Purchase Discount Activity

Mechanical Industry Press Automotive Branch aims to provide knowledge power for China’s automotive industry. To give back to the support from various enterprises and institutions in the automotive industry, we are launching a limited-time “Group Purchase Discount Activity”. Any unit ordering more than 50 copies of books can enjoy group purchase discounts (limited to unit purchases, see book directory for details)!

[Activity Date]May 1, 2023 – September 1, 2023

ØOrder more than 50 copies to enjoy a 32% discount.

If you need to order books, please contact us. We can provide free sample books (1-2 copies)! Thank you for your strong support for the Mechanical Industry Press Automotive Branch!

[Contact Us]

Address: 22, Million Village Street, Xicheng District, Beijing

Group Purchase Hotline: 010-88379735/88379674

Contact Person: Zhang Ping (13031040399, same WeChat)

[Bank Remittance Information]

Account Name: Mechanical Industry Press Co., Ltd.

Account Number:0200 0014 2902 4901 811

Bank: Industrial and Commercial Bank of China, Beijing Million Village Branch

Author: Gao Mengyu

Editor: He Shijuan

Reviewer: Li Jun