Core Function Overview

Siemens has launched a groundbreaking product in the industrial sector—Industrial Copilot, an innovative tool that integrates generative artificial intelligence technology, deeply fused with the Siemens TIA Portal platform, providing users with a one-stop automation solution. This AI assistant not only significantly shortens the time required for generating complex automation code but also effectively reduces the workload of engineering teams through automated virtual tasks and PLC code construction, ensuring the accuracy of complex engineering designs and significantly enhancing the efficiency and quality of the entire development cycle.

From Concept to Reality: The First Industrial-Grade Generative AI Product Launched

At the Hannover Messe 2024, Siemens showcased its first generative artificial intelligence product applied in the field of industrial engineering design—Industrial Copilot. After deep integration with the Siemens TIA Portal system, this AI assistant successfully automates the generation of basic virtual tasks and code for programmable logic controllers (PLCs), automating a large amount of repetitive work, thereby reducing the pressure on engineering teams and improving the quality and accuracy of engineering designs.

From Concept to Scalable Application

As early as the 2023 Hannover Messe, Siemens and Microsoft envisioned the future of generative AI assistants, integrating automation and process simulation information from the open digital business platform Siemens Xcelerator into Industrial Copilot. Meanwhile, leveraging advanced large language models from Microsoft Azure OpenAI services, Industrial Copilot has made breakthrough progress in code creation and optimization for factory automation software.

At the SPS (Smart Production Solutions) exhibition in Nuremberg, Germany, in the fall of 2023, Siemens, in collaboration with Schaeffler, demonstrated the first enhanced production equipment equipped with generative artificial intelligence technology. Subsequently, at the Hannover Messe 2024, Siemens officially launched its first generative artificial intelligence product for engineering applications, marking the transition of this technology from theoretical to scalable practical application.

Empowering Industrial Transformation: Case Studies and User Feedback

The Grenzebach Group, an industrial automation solution provider and a model of small and medium enterprises actively participating in generative artificial intelligence applications, has adopted Siemens Industrial Copilot. Dr. Steven Althaus, CEO of the group, stated: “Generative artificial intelligence has become a key factor in corporate competitiveness.” Through collaboration with Siemens, Grenzebach can fully utilize data resources from industrial sites, enhance human-machine collaboration, effectively address the shortage of technical talent, accelerate technological innovation, and significantly improve production efficiency.

Siemens Industrial Copilot: A New Dimension in Engineering Design

【Integrating TIA Portal to Enhance Engineering Design Capabilities】 Siemens Industrial Copilot is specifically optimized for TIA Portal engineering design, capable of automatically generating code using Structured Control Language (SCL), allowing the TIA Portal platform to directly access AI-generated code suggestions, eliminating the cumbersome steps of manual copying and pasting. Additionally, this AI assistant can interpret SCL code modules, guiding users to easily establish virtual machine or factory models in the WinCC Unified environment. Notably, engineers can search Siemens official manuals using natural language, greatly improving lookup efficiency. To ensure data security, customers can opt to connect to a dedicated Azure OpenAI service instance, avoiding the use of customer data for model retraining.

【Industrial AI Leading Industry Upgrades】 Siemens cleverly introduces industrial-grade generative artificial intelligence into actual workshop scenarios through Industrial Copilot, which is expected to become an indispensable part of engineering processes in the future. With seamless integration with TIA Portal, Siemens is at the forefront, providing generative artificial intelligence products for engineering design to industrial enterprises worldwide. As Rainer Brehm, CEO of Siemens Digital Industries Factory Automation, stated, industrial artificial intelligence is gradually becoming a bridge connecting the real and digital worlds, effectively alleviating the shortage of technical talent, significantly enhancing industrial production efficiency, and strongly promoting the achievement of sustainable development goals.

Looking Ahead: AI-Driven Industrial Assistants Across the Value Chain

Siemens is fully committed to launching a complete series of generative artificial intelligence-driven industrial assistants across all segments of its business value chain, aimed at assisting enterprises in achieving comprehensive transformation and upgrading in design, planning, development, engineering implementation, and work methods. Currently, Siemens is actively promoting the application of generative artificial intelligence assistant solutions in various fields, including automotive manufacturing, infrastructure construction, transportation, medical equipment, general manufacturing, and mechanical engineering, in collaboration with multiple pilot customers and strategic partners.

In summary, Siemens Industrial Copilot, designed for diverse scenarios in design, planning, engineering, operation, and service, with its powerful functionality and ease of use, will further simplify the human-machine interaction process, making it faster and more efficient. In the development process of the automation industry, Siemens Industrial Copilot and the generative artificial intelligence technology it represents not only revolutionize traditional industrial engineering design methods but also point the entire industry towards a development direction filled with opportunities and challenges. The future of industrial automation will increasingly rely on these cutting-edge technologies, which will continue to drive the intelligent upgrade of industries, resulting in higher production efficiency, lower error rates, and more flexible and agile business responsiveness, ultimately assisting the global economy in moving towards a greener, smarter, and more efficient sustainable development model.

CCTV2 reports on Siemens Industrial Copilot

Open Source Industrial Software: Source Code for Industrial-Grade PLM Systems

2024-04-23

Inovance, Zhongkong, Baoxin: Summary of Leading Chinese Intelligent Manufacturing Companies (with a list of mainstream global industrial control companies)

2024-04-21

Nine Steps for Top-Level Design, Planning, and Construction of Digital Factories PPT

2024-04-19

Introduction to Siemens Digital Factory Simulation PlantSimulation Data Interface

2024-04-18

Overview of Six Major Industrial Control Giants in the U.S.: Including a List of Mainstream Global Industrial Control Companies

2024-04-17

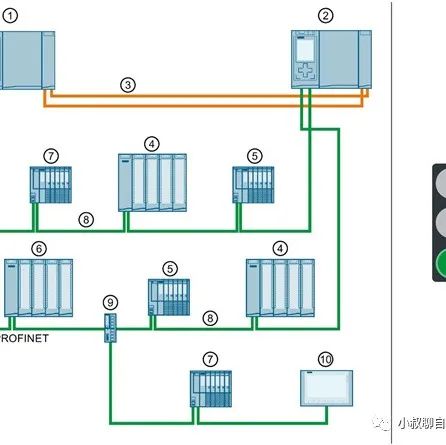

Siemens S7-1500 Redundant Network Configuration Methods and Case Analysis

2024-04-16

Siemens WinCC Data Acquisition System Technology and Engineering Experience Sharing PPT

2024-04-15

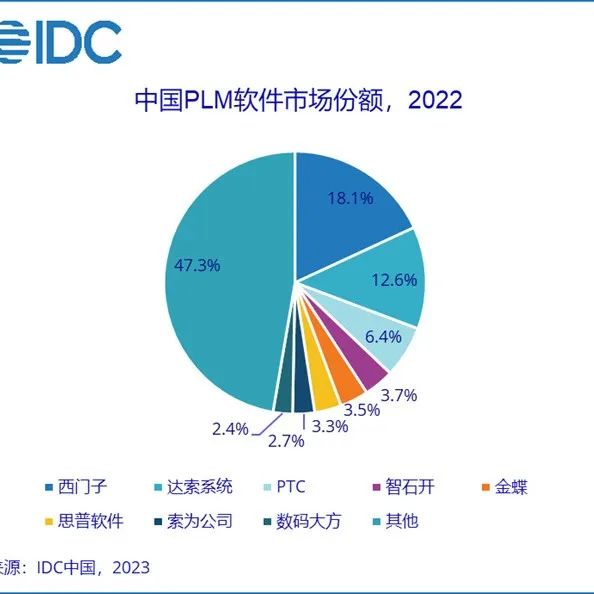

Siemens, Dassault, PTC Lead the Way: Analysis of the PLM Market and Segment Shares in Chinese Manufacturing

2024-04-11

MES/MOM Systems: The Integration of IT Technology and Manufacturing Management Philosophy

2024-04-10

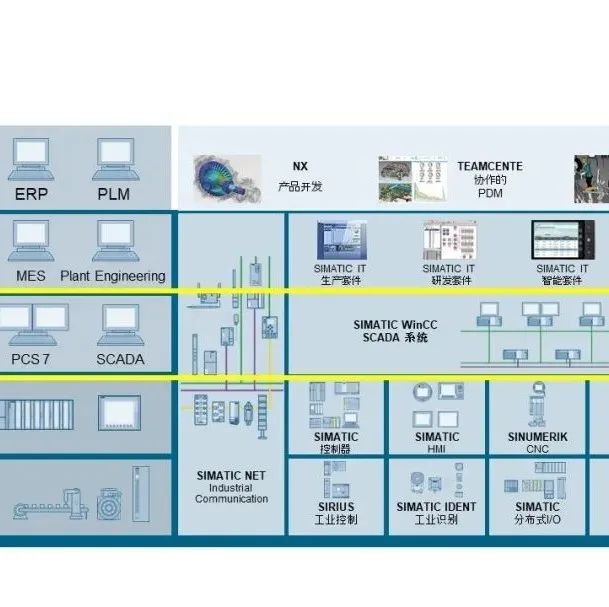

Siemens, Dassault, PTC, ANSYS, Zhongkong: A Comprehensive Analysis of the Global Industrial Software Industry Chain

2024-04-09