The launch of powerful, compact single-board computers has driven the design of new products, and its utility is particularly evident in applications that optimize cost and efficiency through miniaturization. Additionally, visual systems can leverage fully-featured board-level machine vision cameras to further reduce the overall size of products and achieve operational flexibility, while also supporting custom or non-standard optical components. They are used in: medical diagnostics, measurement, robotics, embedded vision, packaging and printing inspection, handheld scanners, desktop laboratories, and other space-constrained systems.

Today, I will provide a detailed analysis of

the important steps to consider when

selecting embedded vision cameras,

such as: functional groups, form factors, and physical space requirements,

interface options, lens mounts, software support,

thermal management, and electromagnetic compatibility.

Form Factors and Functional Groups

When transitioning from packaged cameras to board-level cameras, system designers should carefully consider their imaging and camera performance requirements. Many small board-level cameras only support low-resolution sensors, a limited number of GPIO lines, and have restrictions on the internal functions of the camera. In contrast, many fully-featured machine vision camera board models are simply standard cameras with their housings removed. While these cameras can achieve the desired imaging performance, their size may not be significantly smaller than standard packaged models. These cameras often use standard GPIO and interface connectors, making them unsuitable for embedded applications due to their larger size. For example, the size of traditional industrial locking connectors is comparable to that of a Blackfly S board-level camera.

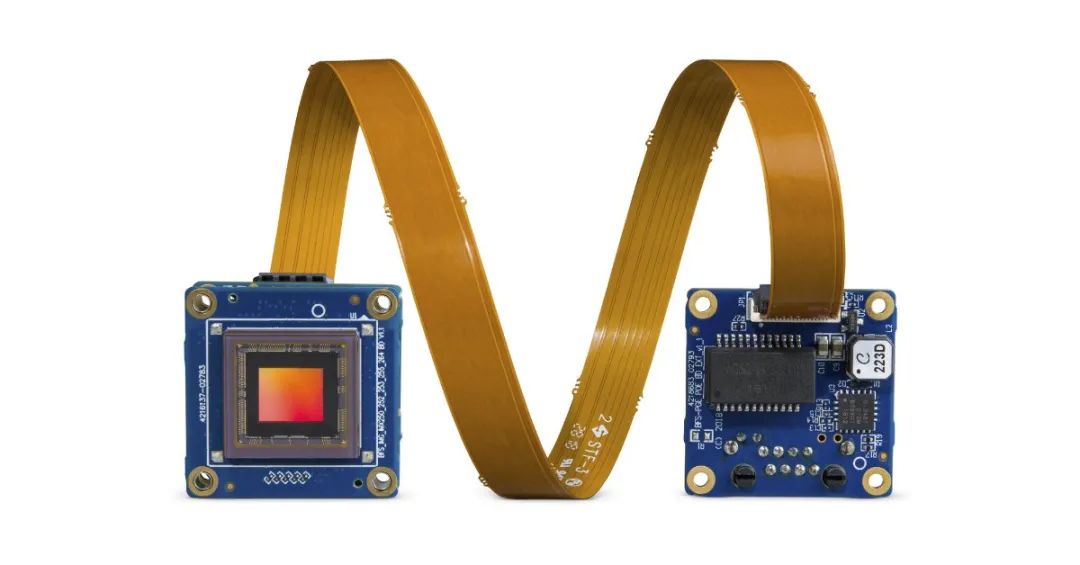

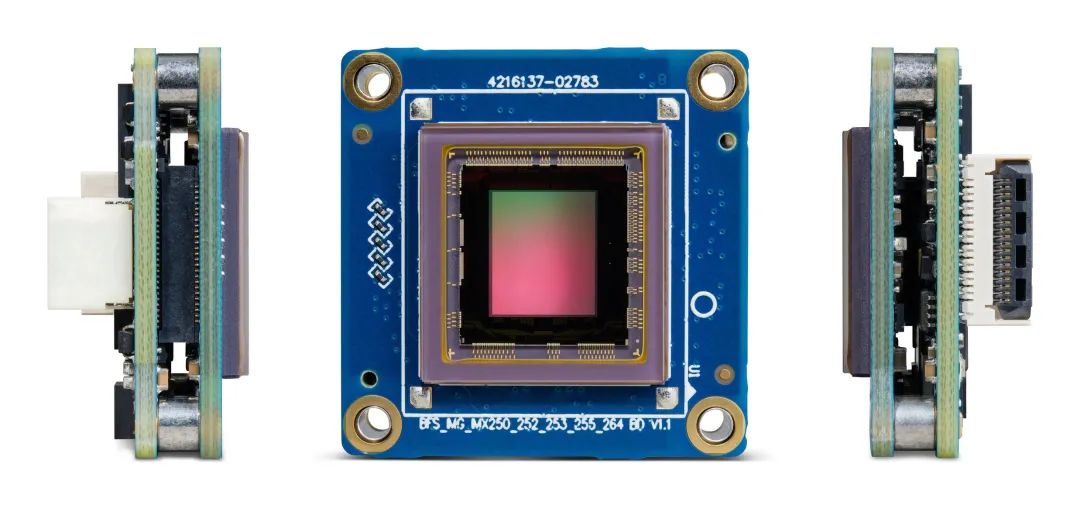

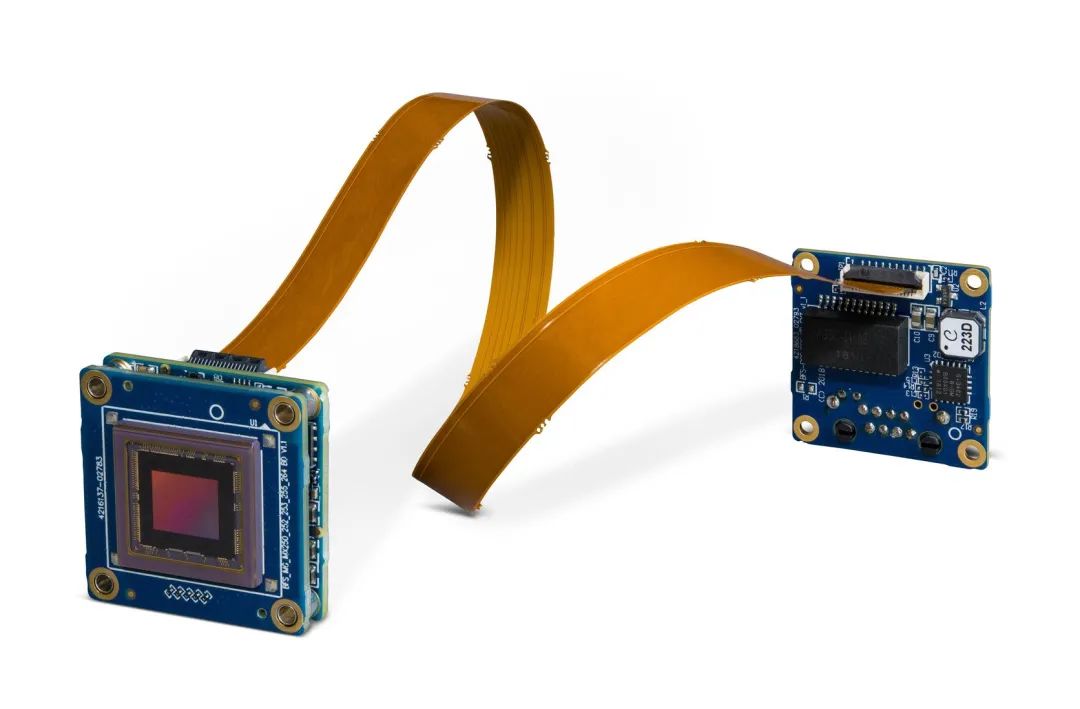

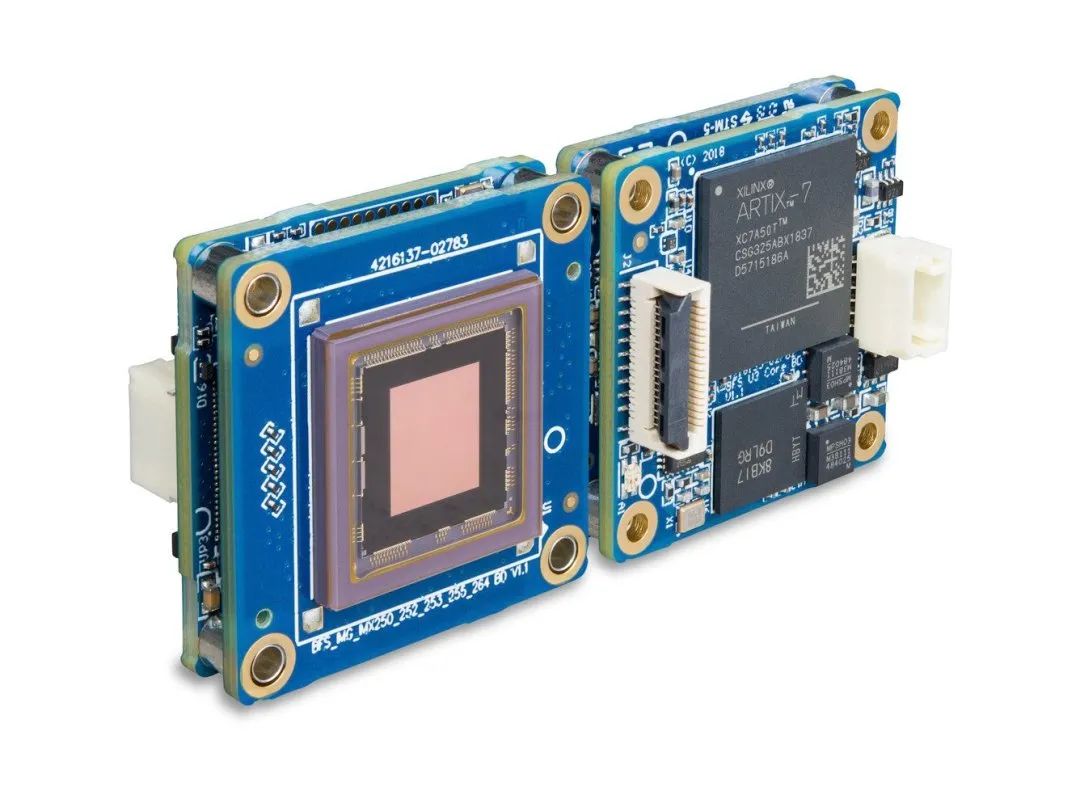

FLIR Blackfly S Board-Level Camera

FLIR’s Blackfly S board-level cameras are designed specifically for embedded systems. They have a compact size of only 29mm x 29mm x 10mm and provide the same imaging performance and full rich features as the packaged Blackfly S models; while the compact GPIO and interface connectors save additional space. Another significant advantage of FLIR’s embedded vision camera products is that all cameras using sensors sized from 1/3″ to 1.1″ share the same form factor, and multiple camera models with a consistent form factor simplify the development and upgrade of systems and future product variants.

Lens Mounts

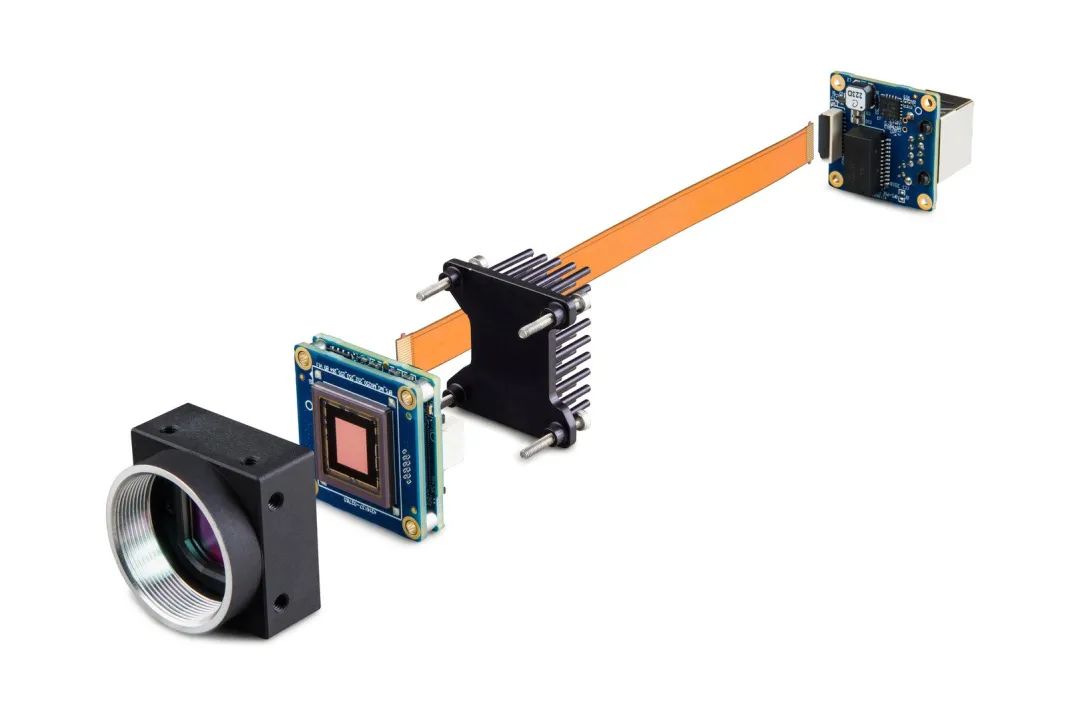

For customers looking to integrate non-standard optical components or place the image sensor as close to the target as possible, board-level cameras are an attractive option. Board-level cameras do not have fixed lens mounts, allowing designers the freedom to choose optical components, and the machine vision industry typically does not use standard C, CS, or S interface lenses. This design is also very suitable for biotechnology and laser beam analysis applications that typically do not require lenses. Another common application for board-level cameras is to integrate the lens mount into another product component, hence referred to as “embedded vision.” Additionally, integrating lens mounts directly into the product housing through molding can effectively simplify manufacturing and assembly, further reducing costs. To evaluate board-level cameras without lens mounts, installation accessories should also be purchased. If the packaged model has the same sensor and functionality as the board-level model, they can serve as a development platform.

When selecting the right lens mount options for board-level cameras, one of the most important factors is the size of the sensor used. Typically, S-type mount lenses are designed for low-resolution sensors of 1/3″ or smaller (usually below 2MP). CS-type mount lenses are designed for sensors from 1/3″ to 1/2″; if the sensor size is 1/2″ or larger, it is best to use C-type mount lenses.

Thermal Management

Packaged machine vision cameras rely on their housing surface area to dissipate heat generated by the sensor, FPGA, and other components. Without a housing, there may be additional design requirements for high-performance board-level cameras to ensure they operate within the recommended temperature range. In this case, providing sufficient heat dissipation is key. Manufacturers typically provide the maximum junction temperature for the hottest components. For FLIR Blackfly S cameras, the specified maximum junction temperature for the FPGA is 105 °C (221 °F).

System designers must ensure that their thermal management solutions meet this specification. The size of the heat sink, the surface area of the rack on which the camera is mounted, or the type of active cooler required depends on the sensor, frame rate, operating environment, and the number of camera image processing tasks being performed. To facilitate the installation of heat sinks on the camera, we recommend using thermal paste on thermal pads to minimize board stress on the camera as much as possible.

Housing Design and Rapid Prototyping

In most cases, board-level cameras are directly integrated into embedded vision systems/products and do not require a housing. However, for applications where the camera is not integrated with a specific product and the internals are exposed to components, it may be necessary to prevent damage with a housing. In rapid prototyping, embedded system designers can easily design and print a camera housing using a 3D printer, or use a generic plastic housing that is large enough to accommodate the camera, then mount the camera in place using spacers and mounting brackets.

Interfaces and Connectors

The first generation USB 3.1 is an ideal interface for embedded systems, its universal functionality ensures support for various hardware from desktop computers to ARM processor-based single-board computers (SBC). Direct Memory Access (DMA) can maintain low latency without the need for filter drivers. The first generation USB 3.1 also uses a single cable for power and can provide data throughput of up to 480 MB/s, effectively simplifying mechanical and electrical designs.

One of the important goals for embedded system designers includes miniaturization of existing designs. In this case, the maximum cable length is far less important than the size of the cable and connectors. Flexible printed circuit (FPC) cables support the first generation USB 3.1 with lengths of up to 30 meters. FPC cables, as the name suggests, are cables that can be bent and twisted to fit tightly packed systems. Additionally, high-quality locking connectors and FPC shielded cables with locking tabs ensure highly secure and reliable connections.

However, the USB 3.1 interface has a potential drawback, as its high-frequency signals can interfere with wireless devices up to 5 GHz (such as GPS signals). For applications using such wireless frequencies, we also offer FLIR board-level cameras with GigE interfaces.

MIPI CSI is another universal interface used by many embedded motherboards. However, compared to USB, the complexity of MIPI protocols and drivers can make development more time-consuming. Low-voltage differential signaling (LVDS) interfaces are also available and are designed for direct connection to host-side FPGAs; however, each signal transmission channel requires two wires, which can be a minor yet significant drawback in certain applications.

Software Support and Electromagnetic Compatibility

When selecting cameras for embedded systems, software support is an important consideration that cannot be overlooked. With SDKs that support both desktop and embedded systems, designers can easily develop vision applications using familiar tools and deploy them on the chosen embedded platform. FLIR’s Spinnaker SDK supports Windows and Linux desktop systems based on x86, x64, and ARM processors.

Without the shielding effect provided by a housing, the electromagnetic compatibility (EMC) of board-level cameras may differ from that of packaged models. All packaged FLIR machine vision cameras are EMC certified, while board-level cameras have not yet undergone this certification. These board-level cameras need to be embedded in other products/systems and therefore require separate certification for the finished product. In any application, we recommend following best practices for electromagnetic interference (EMI) management, just like with other electrical components.

Blackfly S Board-Level

FLIR Blackfly board-level variants belong to the high-performance machine vision area scan cameras, designed for embedding in tight spaces. Unlike many other board-level cameras, it has a rich set of features suitable for the latest CMOS sensors; with the same feature set as the boxed version. With its reliable compatibility, it can be integrated into mainstream SBCs and SOMs at any time. The Blackfly S board-level model features embedded system connectivity, with rich functionalities that enable OEMs to develop smaller, lighter, and lower-cost solutions.

Board-level cameras have revolutionized embedded vision systems, allowing for greater freedom and flexibility in the design of compact, multifunctional innovative products. In addition to the factors mentioned above, attention should also be paid to using high-quality sensors, optical components, and reliable parts to ensure your embedded system is future-proof. FLIR’s full range of board-level cameras is designed for these applications and offers an industry-leading 3-year warranty.

For friends who want to learn more about FLIR machine vision products,

you can click to follow the official WeChat account of “FLIR“

to discuss more professional knowledge together~

Click “Read the Original” to discover more secrets~

FLIR Machine Vision

FLIR’s machine vision division produces and sells over 250 models of visible light cameras, with resolutions ranging from 0.3 million pixels to 3.1 million pixels. The cameras come in various forms, including board-level and closed user interface options, such as USB3, GigE, and 10GigE. FLIR’s machine vision division designs, manufactures, and distributes its cameras and related software to global customers to establish systems that improve the efficiency, quality, analysis, and safety of various processes and products.

Scan to follow us

WeChat ID: FLIR-China