Robots have been around for decades, yet their definition remains subjective and varies from person to person, with no unified opinion. One reason for this ambiguity is that robots are still evolving, with new models and functions continuously emerging. Perhaps it is this vagueness in the definition of robots that allows for ample imagination and creativity.

Various popular science books categorize robots into the following types:

-

Domestic Robots: These assist people with daily life and simple household chores.

-

Operational Robots: These can be automatically controlled, are reprogrammable, multifunctional, have several degrees of freedom, and can be fixed or mobile, used in related automation systems.

-

Program-Controlled Robots: These control the mechanical movements of the robot in a predetermined sequence and conditions.

-

Teaching-Reproducing Robots: These learn movements through guidance or other means and input work programs, allowing the robot to automatically repeat tasks.

-

Numerical Control Robots: These are taught via numerical values, language, etc., and perform tasks based on the taught information. Sensory-controlled robots use information obtained from sensors to control their actions.

-

Adaptive Control Robots: These adapt to changes in their environment and control their own actions.

-

Learning Control Robots: These can “experience” work-related knowledge, possess a certain learning capability, and apply the learned experiences in their tasks.

-

Intelligent Robots: These are robots whose actions are determined by artificial intelligence.

Chinese robotics experts categorize robots into two major categories based on their application environment: industrial robots and special robots.

The so-called industrial robots are multi-joint mechanical arms or multi-degree-of-freedom robots aimed at the industrial sector. Special robots are advanced robots used for non-manufacturing purposes that serve humanity, including service robots, underwater robots, entertainment robots, military robots, agricultural robots, and robotic machines.

Within special robots, some branches are developing rapidly and showing trends toward independent systems, such as service robots, underwater robots, military robots, and micro-operation robots.

Currently, international robotics scholars also categorize robots into two classes based on their application environment: industrial robots in manufacturing environments and service and humanoid robots in non-manufacturing environments, which aligns with the classification in China.

Currently, the most widely installed industrial robots in the world (approximately 26% of the global total) are SCARA robots (Selective Compliance Assembly Robot Arm). The second most installed type (estimated by the author to be nearly 25%) is the series connection articulated arm with six vertical axes. Therefore, these two types of industrial robots account for over half of the global industrial robot installations, making them our focus.

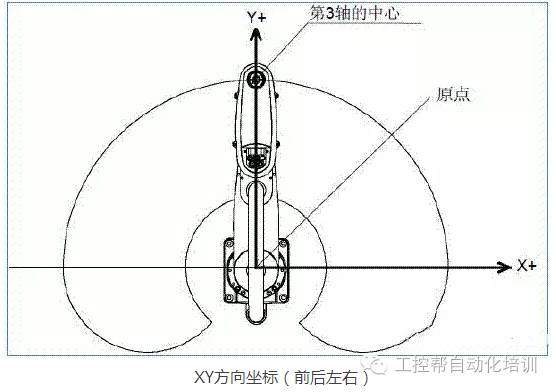

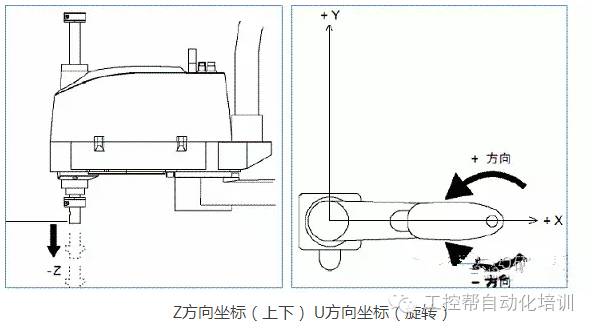

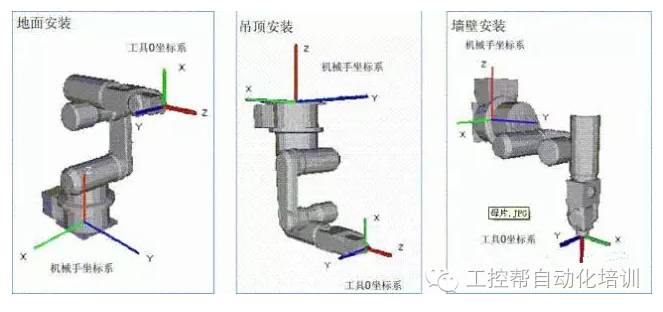

1. Robot Coordinate Systems

(1) SCARA Robot Coordinate System

(2) Vertical 6-Axis Robot Coordinate System

2. Robot Arm Posture

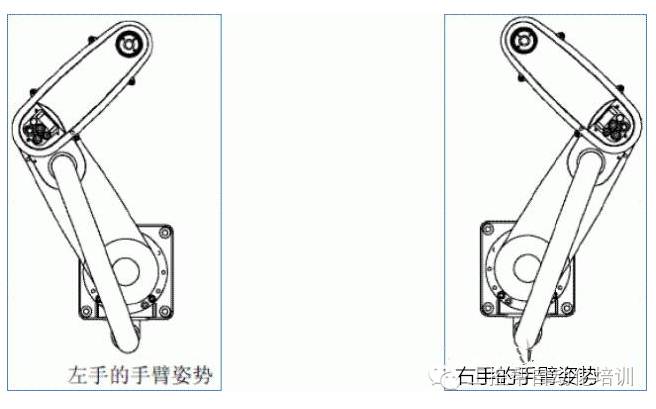

(1) SCARA Robot Arm Posture

When using SCARA robots for tasks, it is necessary to ensure that their arm posture during teaching matches the specified point. If this is not done, slight positional offsets may occur due to different arm postures, or the robot may move along unexpected paths, posing a risk of interference with surrounding equipment. To avoid this, the arm posture at this point must be specified in advance (as shown in the above image). This information can also be modified from the program.

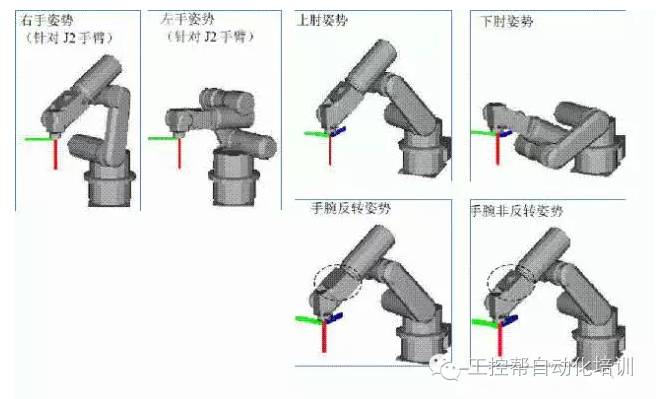

(2) Vertical 6-Axis Robot Arm Posture

The vertical 6-axis robot can move with different arm postures at points within its range of motion, as illustrated above. This information can also be modified from the program.

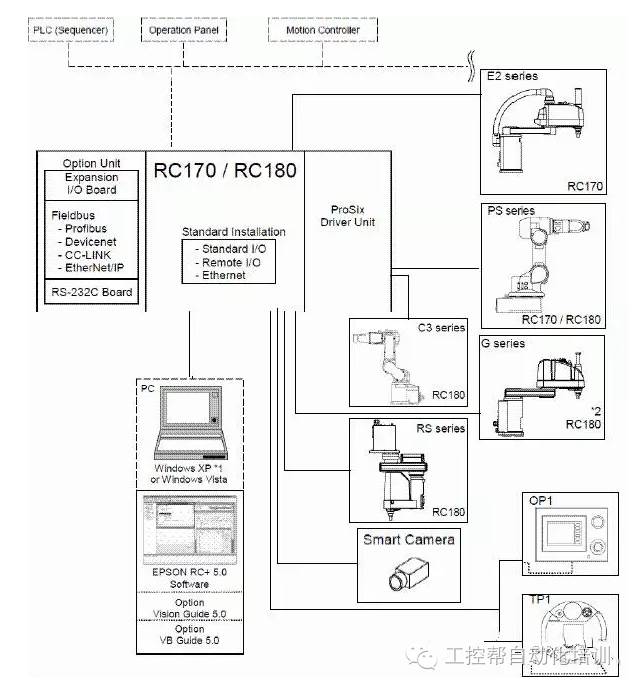

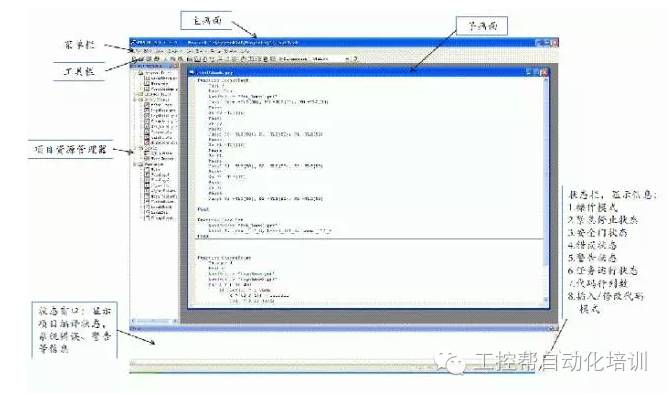

3. Robot Hardware and Programming Interface

Taking a well-known Japanese company’s robot as an example, the hardware system is structured as shown in the following image.

The user programming interface is shown in the following image, with the programming language being a high-level language similar to BASIC that is available for user secondary development. It supports multitasking, motion control, and I/O control.

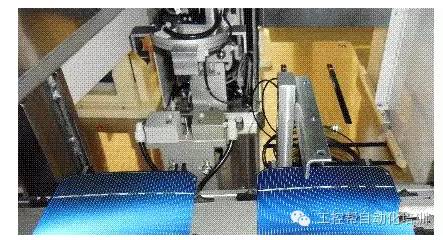

1. Handling of Photovoltaic Cell Panels

The manufacturing of cell panels involves around ten processes, with each workstation requiring the handling of the panels. As the panels become thinner and the combination of high-value and delicate materials makes reducing the breakage rate during handling a primary requirement, the outstanding repeat positioning accuracy and high reliability of robots make them the preferred choice for this task. Below is a three-axis robot for handling cell panels.

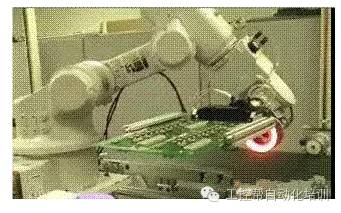

2. Application in PCBA Testing Industry

PCBA (Printed Circuit Board + Assembly) testing is crucial for the quality of circuit board products and the survival of enterprises. Under the dual pressure of labor shortages and product price reductions, using robots to reduce or replace manual labor is an inevitable choice for companies. Below is a schematic diagram of a robot dynamically detecting a circuit board.

3. Assembly of Low-Voltage Electrical Products

Low-voltage electrical products generally include circuit breakers, leakage switches, contactors, relays, etc. These products feature high output, stable demand, and complex assembly. An assembly robot production line can provide stable, efficient, and highly repeatable operations.

Below is a photo of a workstation where a robot installs a cover on a circuit breaker.

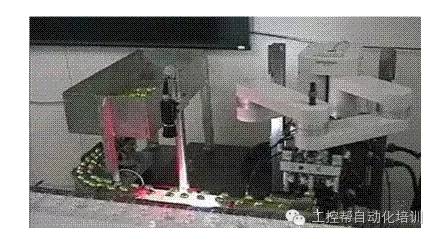

4. Coordination of Robots with Small Welding and Cutting Equipment

As robots and laser equipment become smaller and prices decrease, large robotic welding methods from the automotive industry are widely applied to small robotic welding industries in non-automotive fields. These include pattern cutting of metal sheets, welding of lithium batteries, and cutting and welding of plastic products. Due to the complexity and diversity of trajectories, six-axis robots are predominantly used. Below is a photo of precise cutting operations for non-standard small components.

5. Production Lines for Granular Products

Electronic ICs, surface-mounted components; pharmaceuticals such as capsules, tablets, and pills; and food items like chocolates and candies all fall under granular products. The application of robots in such scenarios primarily involves material handling, with general precision requirements but high-speed demands for continuous 24-hour stable operation. Below is a candy packaging production line.

6. Quantitative Packing Production Lines for Soft Packaging Products

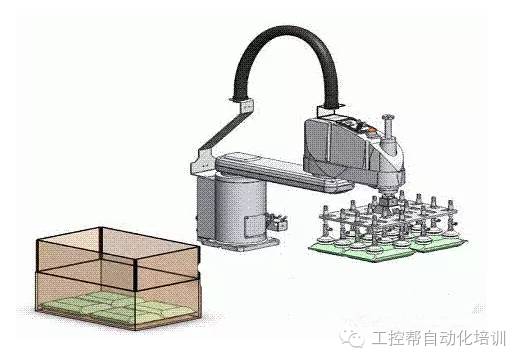

For the convenience of transportation and storage, quantitative packing of products is prevalent in various industries; for example, beverages, beer, and milk in the food industry; injections and powders in the pharmaceutical industry; and small components in the hardware industry. Quantitative packing involves transferring products from a conveyor belt to boxes using vacuum suction or grippers, one or multiple at a time. Below is a schematic diagram of a soft packaging product packing production line using specialized fixtures.

Gongkong Help – A one-stop growth platform for Chinese industrial control talents.

Training programs: PLC system integration + industrial robot integration applications + machine vision + bus communication.

Course consulting with beautiful teaching assistants

Everyone is welcome to follow the Gongkong Help automation training public account to learn about the latest industrial control industry news and trends together. WeChat ID: GKB1508, or scan the QR code to follow us.