Click the blue text to follow us

Scattering the eagle spirits, soaring across the land,

With wisdom and courage, calling for the wisdom of China.

—— “The State Council’s Tribute to Comrade Jiang Shangzhou”

01

Introduction

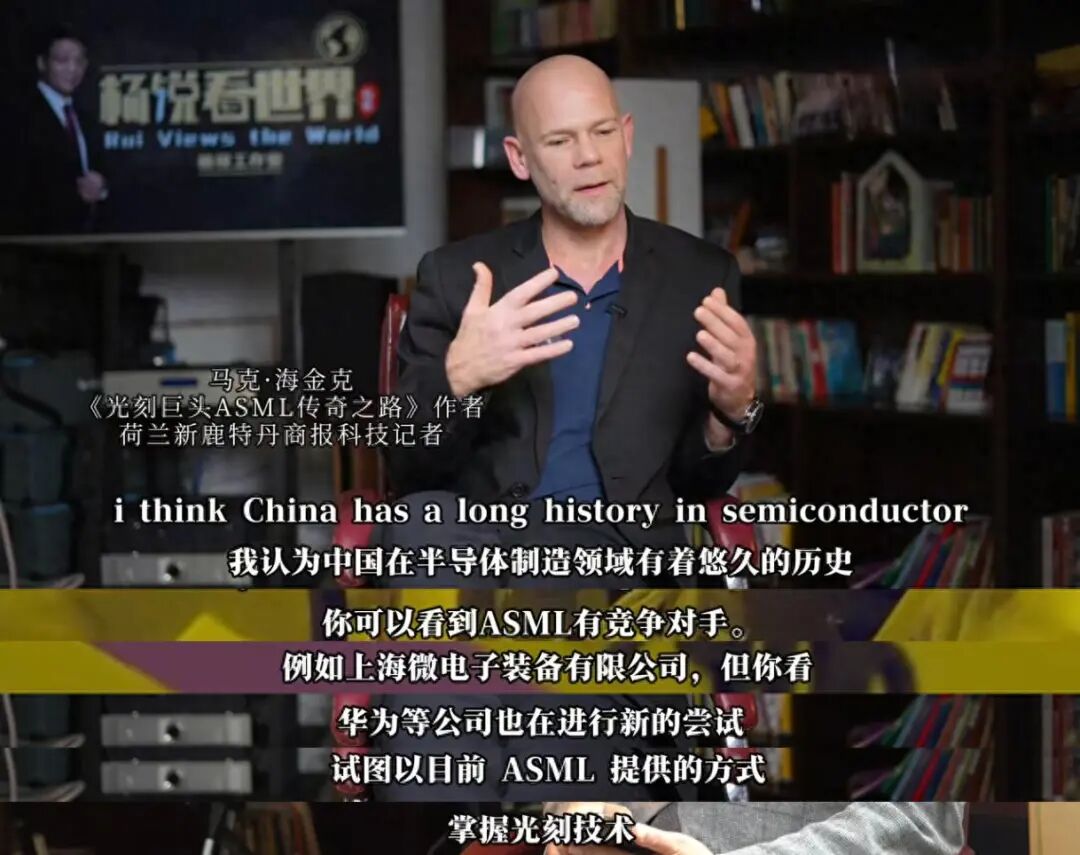

Yang Rui, former host of the English channel of China Central Television, interviewed Dutch journalist and semiconductor observer Mark Heijink about the lithography machine industry and international chip industry issues.

Heijink stated that China has a long history of development in the semiconductor chip field, and some competitors to ASML have emerged among Chinese companies.

These competitors have developed over decades, such as Shanghai Micro Electronics. However, companies like Huawei are now trying to master lithography technology using the technical experience provided by ASML.

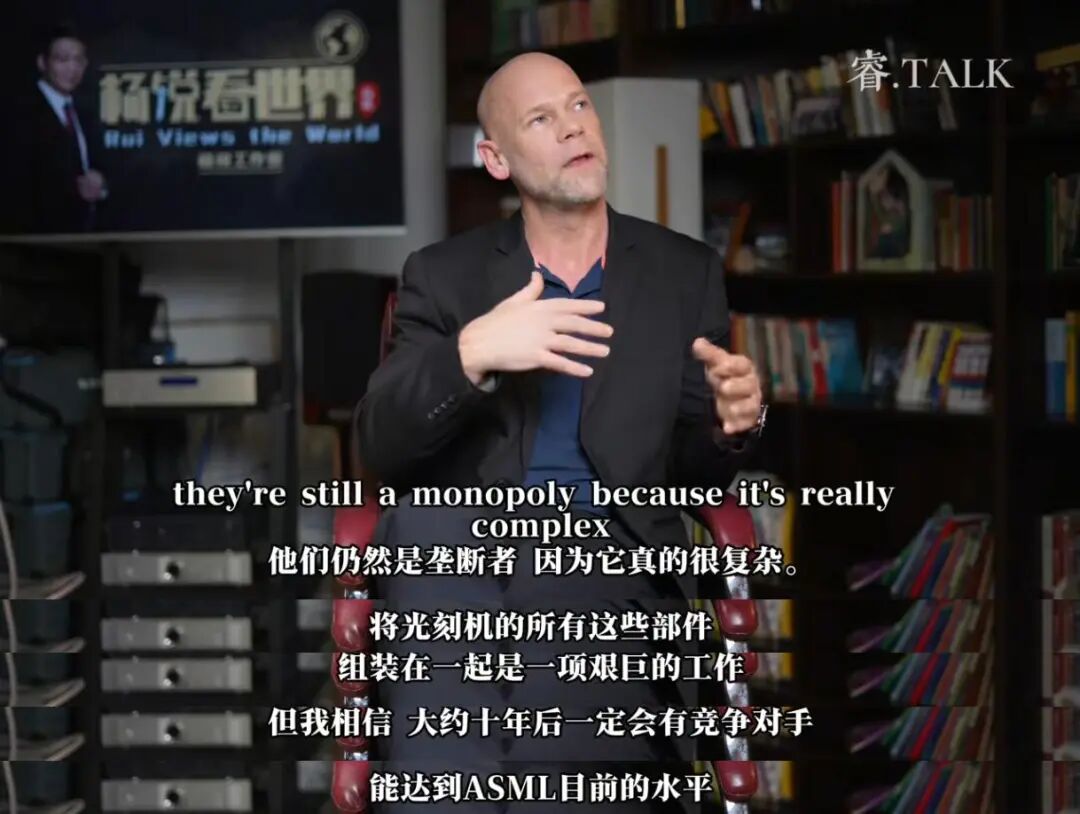

However, until now, ASML remains the monopolist of EUV lithography technology because it is indeed very complex, and assembling all the components together is a daunting task. But I believe that in about 10 years, there will definitely be Chinese competitors reaching ASML’s current level.

02

Continuous Suppression

In 2017, a customer from China purchased lithography equipment from ASML worth a total of 700 million euros.

At the end of that year, then-CEO Peter Wennink stated in an interview with investors that the annual order amount from China had already broken ASML’s new record, which would usher the global chip industry into a new technological era.

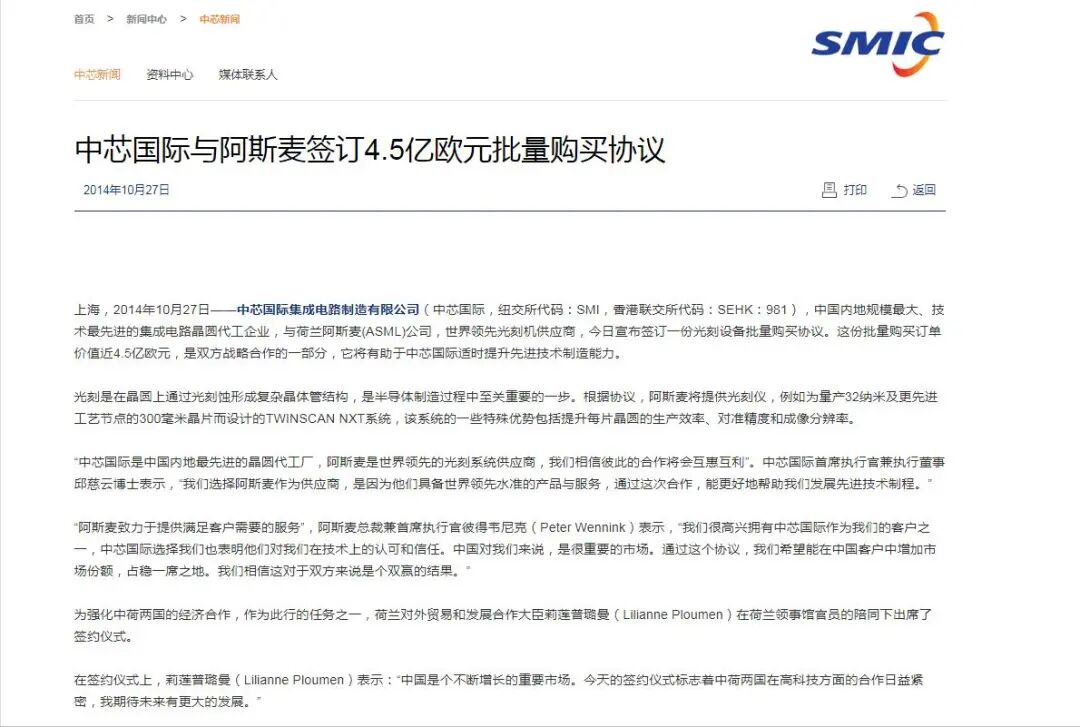

In 2018, the largest wafer manufacturer in mainland China, SMIC, signed a purchase agreement in Shanghai to officially procure an advanced EUV lithography machine from ASML, which was also the first EUV device in mainland China. The purchase amount reached 120 million US dollars, equivalent to SMIC’s entire profit for the previous year.

ASML’s supervisory board believes that cooperating with China on EUV equipment poses significant risks, and the US government will intervene.

However, ASML’s management disagrees. Since 2014, ASML has signed numerous contracts for equipment procurement with SMIC, and ASML is located in the Netherlands, a neutral country, not involved in political stances. The US government has no reason to obstruct ASML’s cooperation with the Chinese market.

Meanwhile, ASML and Chinese companies have established three rules: Chinese companies can only use the equipment with the assistance of ASML employees and are not allowed to inquire about sensitive technology. Chinese companies have also assured ASML that they strictly adhere to intellectual property laws and will not seek to explore the manufacturing technology of lithography machines.

Although ASML and Chinese companies have reached a consensus, and their cooperation is compliant and legal, the US government continues to pressure the Dutch government to prohibit ASML from delivering EUV equipment to Chinese companies.

According to Mark Heijink in his book: US government security advisor Tim Morrison has visited the Netherlands multiple times to talk with relevant representatives of the Dutch government, and personnel from the US Department of Defense, State Department, and the White House have all begun to diplomatically exert pressure on the Netherlands.

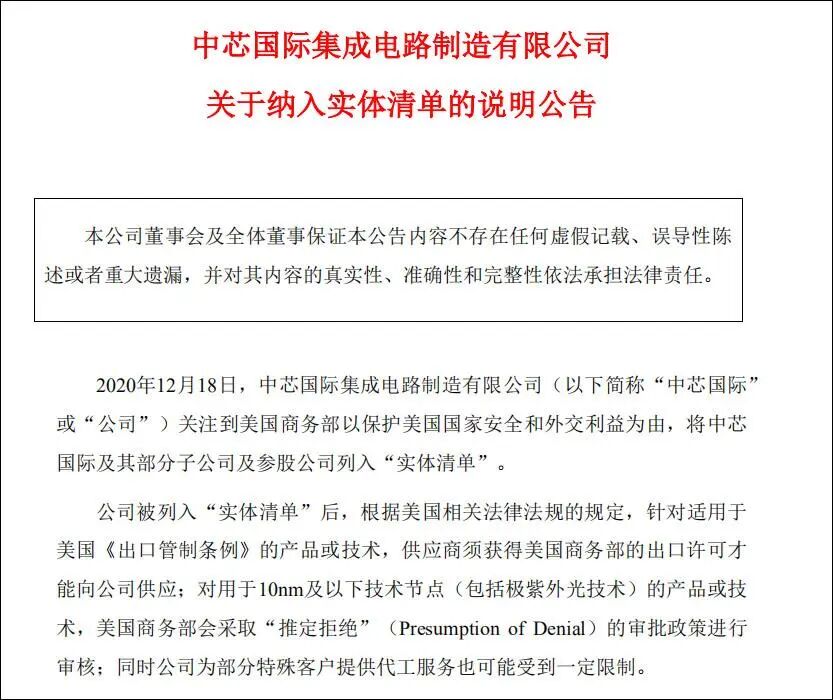

Under the multifaceted pressure from the US government, the procurement of EUV equipment by Chinese companies from ASML was successfully intercepted.

Not only was SMIC’s equipment intercepted, but South Korean company SK Hynix also attempted to purchase an EUV device for its factory in Wuxi, China, but under pressure from the US government, this lithography machine was also halted.

03

Technical Solutions

Although China’s EUV equipment has been completely intercepted, Chinese companies still possess immersion DUV equipment previously purchased from ASML, which can manufacture more advanced chips through multiple exposure techniques.

However, to achieve mass production of advanced chips using multiple exposure technology, the backend deposition and etching equipment must have sufficiently strong technical levels.

According to Heijink’s professional market analysis, a chip manufacturer using immersion DUV equipment to produce more advanced chips through multiple exposures will invest 20% of the total investment in lithography machines, while the remaining 80% will be invested in backend manufacturing technology.

If EUV technology is adopted, then 30% of resources will be invested in lithography machines, and 70% will be invested in backend equipment.

Establishing a DUV + multiple exposure wafer production line will cost over 15 billion US dollars and will soon face technical bottlenecks and subsequent technological development difficulties.

From a long-term perspective, using EUV equipment offers the best cost-performance ratio, while the DUV + multiple exposure solution can only be considered a desperate technical means.

The way Chinese companies achieve mass production of 7nm chips is by adopting the DUV + multiple exposure solution. Although Chinese companies cannot obtain front-end EUV equipment, they have strong explosive power in backend manufacturing equipment.

Local equipment companies from China, such as North Huachuang, Shengmei Semiconductor, Zhongwei Semiconductor, and Shenzhen Xinkailai, have achieved independent technological output in various backend manufacturing equipment such as deposition equipment, etching machines, cleaning machines, and testing machines, realizing a complete process integration of the backend manufacturing industry chain.

Heijink clearly stated in his interview with Yang Rui: The US policy of restricting China from using certain technologies is the best motivation for Chinese engineers to develop domestic semiconductor toolkits. I believe this has actually stimulated the Chinese, forcing them to find their own technological path.

Classic Review of Previous Issues: 200,000+ Reads

Chinese Academy of Engineering Academician: Only 4% Stay in China, Serious Talent Shortage

Chinese-American: China’s 7nm is playing a digital game, with a 10-year gap from the US

Former TSMC R&D Director: China is being choked because the industry is not profitable, and no one is making equipment

USTC Professor: Making 5nm chips is more than ten times harder than making atomic bombs

Classic Review of Previous Issues: 400,000+ Reads

A Chinese who once contributed to American chips was strangled by the US for helping China develop technology

He is a Chinese expert in lithography machines, who has never interacted with the mainland

Chinese Academy of Engineering Academician: 85% choose to work in the US, serious talent shortage

Classic Review of Previous Issues: 1,000,000+ Reads

Academician of the Chinese Academy of Sciences Criticizes Engineering Academician: No ability, no achievements after leaving Lenovo