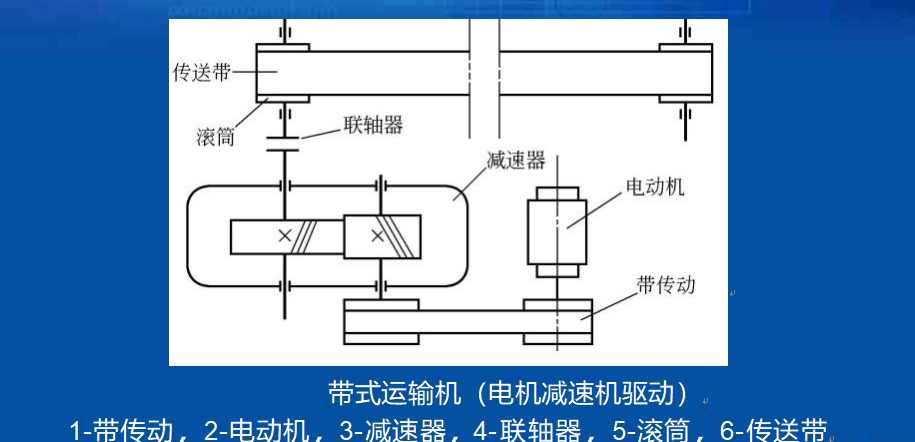

1. Types of Belt Conveyor Drive Devices:The composition forms of belt conveyor drive devices are as follows: 1. Drive device composed of motor and reducer This drive device mainly consists of a motor, hydraulic coupler, reducer, coupling, drive drum, brake, and one-way clutch. 2. Electric drum drive device The electric drum integrates the motor and reducer (planetary reducer) within the drum shell. The heat dissipation inside the shell can be achieved through air cooling or oil cooling, thus it can be classified into oil-cooled electric drums and air-cooled electric drums based on the cooling medium and method. 3. Drive device composed of motor and reduction drum This drive device consists of a motor, coupling, and reduction drum. The so-called reduction drum is where the reducer is installed inside the drive drum, while the motor is placed outside the drive drum. This configuration is beneficial for the cooling and heat dissipation of the motor, as well as for the maintenance and servicing of the motor.2. Components of the Drive Device:1. Motor Generally, a high-efficiency Y series asynchronous motor is used, which is an upgraded version.2. Hydraulic Coupler The main components of the hydraulic coupler include: pump wheel, turbine, rotating outer shell, input shaft, output shaft, spoon tube, large and small drive gears, main oil pump, and auxiliary oil pump.3. Reducer The commonly used reducer for belt conveyors is the cylindrical gear reducer. Common types include JZQ, ZQ, ZL, and ZS models. 4. Drive Drum The drive drum is the main component for power transmission. The structure of the drive drum for belt conveyors is generally a welded steel plate structure, using rolling bearings. The drum can have various surfaces such as smooth, herringbone rubber surface, diamond rubber surface, and parallel rubber surface. 5. Coupling Couplings include cross slider couplings, powder couplings, pin couplings, and brake wheel couplings.3. Methods to Enhance the Drive Capacity of Belt Conveyors:1. Increase the clamping force of the conveyor belt on the drum 2. Increase the wrap angle of the conveyor belt on the drum 3. Improve the friction coefficient between the drum and the conveyor belt.