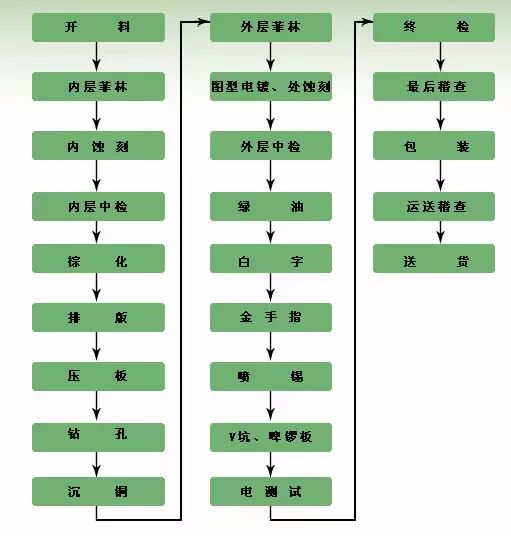

Most engineers send the PCB files or Gerber files to the manufacturer and then wait for the boards to be returned. However, many hardware development professionals may work for years without the opportunity to visit a PCB manufacturing facility to see the entire production process.

Today, I will take you on a tour to see the complete process. (Source: Hardware’s Ten Thousand Whys)

Step 1: Material Preparation

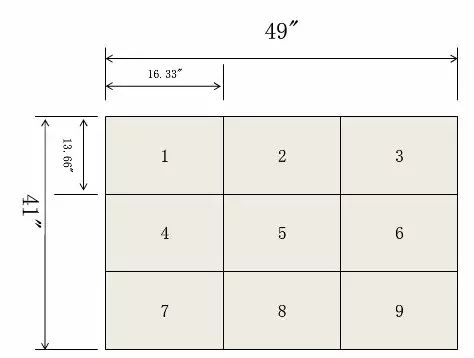

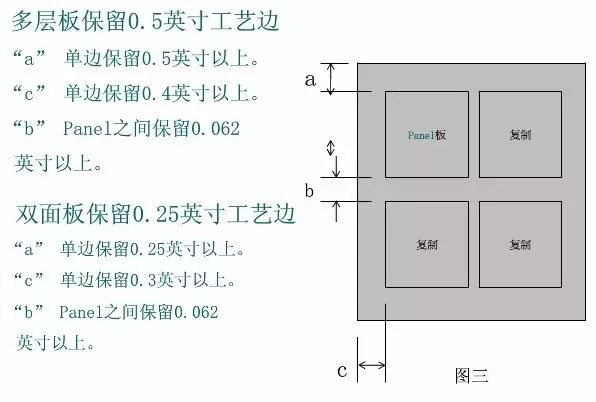

The raw materials for PCB manufacturing are generally in sizes of 1020mm×1020mm and 1020mm×1220mm. If the dimensions of the single board or panel do not fit well, a lot of raw material waste will be generated during the PCB production process. The PCB manufacturer will add the cost of this waste to your board, making your PCB unit price higher. If the board size is well designed, and the dimensions of the single board or panel are a fraction of the raw material size, then the utilization rate of the raw material will be maximized. The PCB manufacturer can cut the material easily, producing the most boards from the same raw material size, resulting in the lowest unit price for the single board.

We cut the purchased copper-clad laminate into the required sizes, which is called material preparation.

Material preparation equipment: (cutting large boards into smaller ones)

The earliest copper-clad laminate consists of a dielectric layer with copper on both sides.

The above image shows a cross-section of the copper-clad laminate.

Step 2: Layout

Step 3: Film Generation

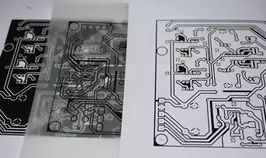

The graphic files provided by the customer are imported and modified using software, and the final graphics are output onto film. This means converting the Gerber files you provided to the manufacturer into film.

Film refers to photosensitive film, also known as film, made from PC/PP/PET/PVC materials. It generally refers to photographic film, but can also refer to the negatives used in printing. The film is always black.

Step 4: Exposure

A layer of photosensitive liquid is coated on the surface of the copper-clad laminate, dried at 80 degrees Celsius, and then the film is applied to the PCB board. It is then exposed using a UV exposure machine, and the film is removed.

The image below shows the exposure machine:

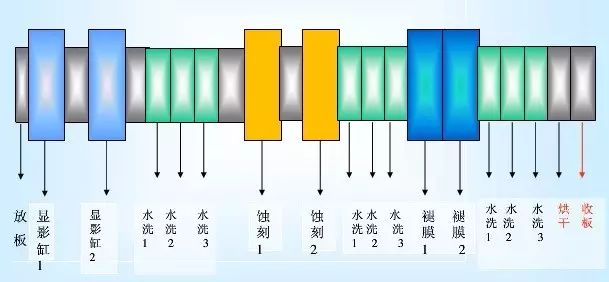

Step 5: Etching

The etching process can be broken down into the following steps:

PCB etching machine

The board flows under the rollers

Why are the etching methods for inner and outer layers of PCB different?

Inner layer: Development → Etching → Stripping

Outer layer: Development → Copper plating → Stripping → Etching → Stripping

Why is this done? Isn’t the outer layer etching process more complicated?

The inner layer generally has larger line widths and spacing, so the ring is sufficient; the outer layer generally has denser lines with limited space, so it is necessary to find a way to achieve the purpose of making lines in the limited space. Alkaline etching can achieve a ring of 1~2 mils, but acid etching requires about 5 mils, so it is necessary to use tin to protect the required lines. Alkaline etching should be avoided wherever possible because it is more expensive than acid etching. The etching factor is a factory’s manufacturing capability and cannot be improved through processes. The etching capabilities of acid and alkaline etching are simply different.

Step 6: Drilling

The machine drills holes in the PCB according to the sizes and coordinates specified in the files.

For non-metallic holes, the PCB factory must use dry film or perform secondary drilling or plug with glue particles. Regardless of the method, it will increase the cost for the board factory. Therefore, if you do not specify, the factory will generally make metallized holes for you.

Step 7: Copper Plating

Copper plating involves depositing a layer of chemical copper on the non-conductive substrate (hole walls) and copper surfaces.

Step 8: Green Oil and Characters

PCB Low-Temperature UV Machine,Purpose: Ultraviolet (UV) Coating Curing

Character brushing:

Character screen printing

Final Step: Comprehensive Inspection

During sample processing, the factory generally does not use fixtures for testing, relying on manual testing; if in small batches, the factory needs to create test fixtures to test the impedance and connectivity of all traces.

ITTBANK Classic Original Recommended Articles (Reply with the corresponding red number to view)

Mobile:

A1, 2015 well-known domestic mobile ODM/OEM solution companies, have you seen it?

A2, Summary of Qualcomm, MTK, Spreadtrum, and Hisilicon mobile main control chips

A3, Overview of the entire mobile industry chain (very comprehensive, highly recommended)

A4, Supply chain revelations of Apple, Samsung, Coolpad, and Xiaomi

A5, Comprehensive summary of Apple’s supply chain

A6, iPhone 6s chip suppliers and component suppliers (worth collecting)

Tablets:

B1, Summary of the domestic tablet industry chain

B2, Top 100 domestic MID (tablet) solution companies

B3, Comparison table of five major tablet processors: Intel, Rockchip, Allwinner, Amlogic, and MediaTek

Set-top Boxes:

C1, Detailed introduction of digital set-top box and OTT set-top box manufacturers (about 100)

C2, Comparison of main control chip manufacturers for network players

Security:

D1, Top 100 domestic security companies and their detailed introductions (Top 100)

Smart Wearables:

E1, 2015 wearable device manufacturers (including representative works and solutions) and their chip supply chains

E2, Recently popular smartwatch companies and their representative products (including solutions) (65 companies)

E3, Smart bracelet companies and their representative products (including solution introductions) (mainstream 50 companies)

Dash Cameras:

F1, Main control chip companies for dash cameras and their solution introductions

Drones:

G1, Overview of the drone industry chain (including representative manufacturers and their representative products)

Robots:

H1, 2016 Top 50 most influential robot companies (Top 50)

Internet of Things:

I1, Summary of IoT WiFi/BT/ZigBee chips or modules

VR:

J1, 2016 hot VR industry chain and its manufacturers

K1, 2015 Top 100 Shenzhen enterprises (Top 100)

K2, 2015 Top 50 global electronic manufacturing services (EMS) factories (Top 50)

K3, Ranking of China’s printed circuit industry (Top 100 PCB companies)

K4, Top 60 integrated circuit design companies and original manufacturers in mainland China (collectible)

K5, Top 20 global semiconductor packaging and testing factories (Top 20)

K6, Top 30 global integrated circuit wafer foundries (Top 30)

K7, Top 50 electronic component distributors in mainland China

LCD Screens:

L1, Top 40 global LCD panel manufacturers (Top 40)

L2, Domestic LCD module manufacturers in China

L3, LCD display driver chip manufacturers and their IC model parameters

L4, Global LCD screen and module manufacturers (including small and medium-sized models, parameters, applications)

L5, Comparison table of vehicle-mounted display manufacturers and model parameters

L6, Manufacturers of small-sized screens used in smart wearables and their model introductions

Capacitive Touch:

M1, Top 50 touch screen manufacturers (Top 50)

M2, Touch control chip design original manufacturers and their specific chip model specifications

Cameras:

N1, Top 30 camera module manufacturers (Top 30)

N2, Global camera lens manufacturers (25 companies)

N3, Global camera motor manufacturers (Top 20)

Storage:

O1, Memory storage manufacturers and the differences between ROM, SDRAM, RAM, DRAM, SRAM, FLASH, EMMC

WiFi:

P1, WiFi module manufacturers and their solution providers (Top 30) (including chip original manufacturers)

GPS:

Q1, GPS manufacturers and their product introductions

Fingerprint Recognition:

R1, Top 20 fingerprint recognition chip manufacturers (Top 20)

Batteries:

S1, Introduction to power IC original manufacturers (Top 80)

S2, 2015 global BMS (Battery Management System) manufacturers

S3, Overview of the lithium battery industry chain and the top 10 competitive brands in 2015

Wireless Charging:

T1, Summary of six major wireless charging technologies, how many do you know?

MCU:

U1, Overview of globally renowned MCU manufacturers and their detailed introductions

LED:

V1, LED chip manufacturers (with detailed introductions)

Connectors:

W1, Ranking of global connector manufacturers and their detailed introductions

Crystal Oscillators/Capacitors/Inductors:

X1, Overview of global crystal oscillator manufacturers

X2, Ranking of global capacitor manufacturers

X3, Global inductor manufacturers and companies (50 companies)

Sensors:

Y1, Mainstream sensor manufacturers and foundries

AB1, Detailed introduction to optical modules (collectible)

AB2, What is Industry 4.0? This down-to-earth article tells you!

AB3, The ADAS market is huge, are you in the right position?

ITTBANK : Our world is changing because of technology!

Cloud Egg (ittstore)

IC Bank: There is no inventory in this world, just misplaced items!

Global Maker Conference (ITTChina): If you are a maker, please come in!

Welcome to join the ITTBANK QQ group QQ group

Note: Each person is limited to join one group (you can only join one group, if you join multiple groups you will be rejected, please understand!)

Welcome to join QQ group 199699487 — Amlogic S802/S805/S812 and other solution platform network players

Welcome to join the dash camera QQ group: 294132591 — The most professional dash camera review group

1. Mobile industry technology exchange group 3 (134917677)

2. Tablet technology exchange group (378173769)

3. Set-top box OTT box exchange group (361764225)

4. Capacitive touch technology exchange group 2 (257209943)

5. Camera technology exchange group (377648136)

6. LCD screen technology exchange group 2 (249572580)

7. Wireless WiFi technology exchange group 2 (416431905)

8. Security technology exchange group (308535073)

9. Memory storage exchange group (204191613)

10. Mobile, MID, capacitive touch, LCD screen trading group (374763457) — Exclusive sales and procurement group

11. Cross-border e-commerce exchange (384299409)

12. Global maker space (188561451)

13. Global electronic technology exchange platform (370733047) — (This group is purely a technical exchange group, exclusive for technical engineers, traders are not allowed! Thank you! When joining the group, please add a standard note, region + industry + nickname, for example, Shenzhen – Bluetooth WiFi solution – Engineer Xie!)

Submission email: [email protected]

ITTBANK Customer Service Hotline:

400-0933-666

Click “Read the original text” to enter the ITTBANK micro mall