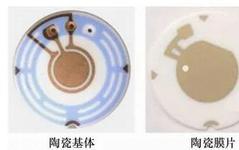

Methods for Controlling Dimensional Accuracy of Dry Pressed Ceramic Sensors

1. Mold Design and Optimization In the production process of dry pressed ceramic sensors, the design and optimization of molds have a crucial impact on the dimensional accuracy of the products. The mold not only determines the shape and size of the product but also directly affects the flowability of the powder and the uniformity … Read more