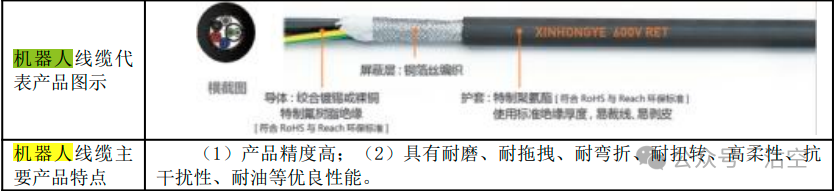

China Dingli Co., Ltd.The humanoid robot is the core strategic business for the company’s future development. The company’s subsidiary, Anhui Ruisi Bo Co., Ltd., focuses on expanding the business related to humanoid robot component assemblies. The company’s current technical team possesses core competitive advantages in the field of harmonic drive products, and the relevant production line equipment is currently being debugged. At the same time, the company’s existing sealing, rubber, and lightweight businesses are also applied in the robotics field. Sealing products, rubber products, and connecting rod products related to humanoid robots are also being developed simultaneously, with some products already completed for designated matching. The company is currently focused on producing harmonic reducers and will gradually expand into related product areas such as force sensors, ultimately achieving the production and manufacturing of robot joint assembly products. Currently, the company and its subsidiaries have signed strategic cooperation agreements with Zhejiang Wuzhou Xinchun Group Co., Ltd., Shenzhen Zhongqing Robot Technology Co., Ltd., and Aifute Intelligent Equipment Co., Ltd. to enhance the company’s core advantages in humanoid robot component assembly products and accelerate the production support of the company’s robot harmonic reducers and component assembly products. Relevant businesses are currently being accelerated.In March 2025, Anhui Zhongding Sealing Co., Ltd. signed an “Investment Agreement” with the People’s Government of Baohe District, Hefei City, planning to build a headquarters for intelligent robot projects and a core component R&D and manufacturing center in Baohe District, with a total investment expected to be 1 billion yuan.AmperelongThe company’s force sensors include unidirectional force sensors and torque sensors, which can be used in robotics and automotive fields. In the field of force sensors for robots, the company collaborates with Tianji Intelligent to develop force sensors based on MEMS silicon strain gauges + glass micro-melting technology. These products can be widely applied to the joint modules of robots, capable of real-time sensing the torque of each joint and controlling the end force, improving the safety and interaction performance of robots to meet the precise measurement needs of force for industrial robots, collaborative robots, and can also be applied in humanoid robots. During the reporting period, the company’s unidirectional force sensors and torque sensors have completed development.Ke Li SensorsIn the first quarter of 2025, a strategic investment in Kepler Robotics was completed.During the reporting period, the company’s six-dimensional force/torque sensors have completed the product series development for humanoid robot wrists, ankles, industrial arms, and collaborative arm ends, mastering key technical points such as structural decoupling, algorithm decoupling, and high-speed sampling communication, and have provided samples to over 50 domestic humanoid robot, collaborative robot, and industrial robot customers, with some customers entering the bulk order stage.Zhaomin TechnologyLeveraging years of development experience in special engineering plastics and precision component manufacturing, the company actively responds to customer needs, using precision molds and advanced processes to solve manufacturing challenges, successfully developing multiple new precision components for humanoid robots in collaboration with customers.Xinhongye In the field of humanoid robots: the company accurately perceives the stringent requirements for high-precision movements in humanoid robots and has successfully developed a series of ultra-flexible cable products. This series has achieved significant technological breakthroughs, focusing on lightweight, high flexibility, anti-interference, and environmental resistance, greatly exceeding the dynamic bending life limits of ordinary industrial robot cables in confined spaces, and can perfectly adapt to various complex application scenarios such as industrial production and medical services. Currently, the company has successfully entered the supply chain system of leading humanoid robot companies, providing highly customized cable solutions for their joint drive systems and dexterous hands.Jiangnan YifanThe company has currently established a specialized motor R&D team covering robotics, barrier gates, logistics, and E-bikes, laying a solid foundation for subsequent product iterations and technical reserves through optimized resource allocation.Donghua TestingThe Donghua Calibration Laboratory has become one of the first CNAS laboratories in China capable of testing multi-dimensional force/torque sensors for robots.

In the field of humanoid robots: the company accurately perceives the stringent requirements for high-precision movements in humanoid robots and has successfully developed a series of ultra-flexible cable products. This series has achieved significant technological breakthroughs, focusing on lightweight, high flexibility, anti-interference, and environmental resistance, greatly exceeding the dynamic bending life limits of ordinary industrial robot cables in confined spaces, and can perfectly adapt to various complex application scenarios such as industrial production and medical services. Currently, the company has successfully entered the supply chain system of leading humanoid robot companies, providing highly customized cable solutions for their joint drive systems and dexterous hands.Jiangnan YifanThe company has currently established a specialized motor R&D team covering robotics, barrier gates, logistics, and E-bikes, laying a solid foundation for subsequent product iterations and technical reserves through optimized resource allocation.Donghua TestingThe Donghua Calibration Laboratory has become one of the first CNAS laboratories in China capable of testing multi-dimensional force/torque sensors for robots.