The so-called backlight source (BackLight) is a type of light source located behind the liquid crystal display (LCD), and its luminous effect directly affects the visual effect of the liquid crystal module (LCM).The liquid crystal itself does not emit light; it displays graphics or characters as a result of modulating light.The development of backlight sources can be traced back to World War II.At that time, ultra-small tungsten filament lamps were used as backlight sources for aircraft instruments.This was the initial stage of the development of backlight sources.After half a century of development, backlight sources have become an independent electronic discipline and gradually formed a hotspot for research and development.

With the continuous development of liquid crystal display technology, the application fields of liquid crystal displays, especially color liquid crystal displays, are also constantly expanding.Driven by the market for liquid crystal displays, the backlight source industry is flourishing.LCDs are non-emissive display devices that require backlight sources to achieve display functionality.

The performance of backlight sources not only directly affects the imaging quality of LCDs but also accounts for 30-50% of the cost of LCD modules, with power consumption accounting for 75% of the module, making it a crucial component in LCD modules.High-resolution, large-size LCDs must be paired with high-performance backlight technologies; therefore, as the LCD industry strives to explore new application fields, the high performance of backlight technology (such as high brightness, low cost, low power consumption, and slimness) also plays a crucial role behind the scenes.

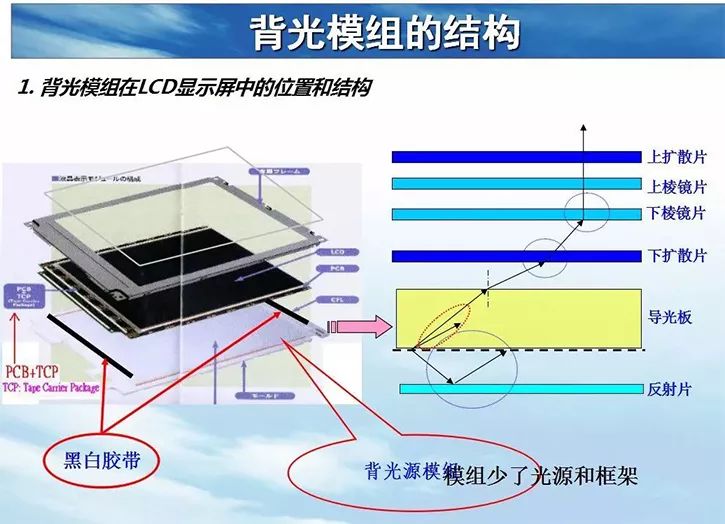

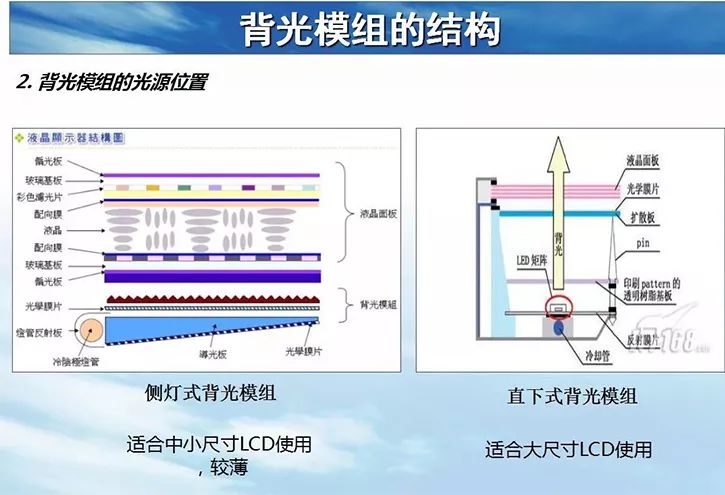

The backlight source provides the light source for the LCD panel.It mainly consists of a light source, light guide plate, optical film, and plastic frame.Backlight sources feature high brightness, long lifespan, and uniform light emission.Currently, there are three main types of backlight sources: EL, CCFL, and LED, which can be classified into edge-lit and direct-lit (bottom-backlit) based on the distribution of the light source.As LCD modules continue to develop towards brighter, lighter, and thinner designs, edge-lit CCFL backlight sources have become the mainstream in the development of backlight sources.

Role of LCD Backlight Modules

The backlight module (Backlight Module) is a rear light source component in LCD display products, generally composed of backlight sources, multilayer backlight materials, and support frames.The quality of the backlight determines the brightness, light uniformity, color gradation, and other important parameters of the liquid crystal display, significantly influencing the luminous effect of the liquid crystal display.

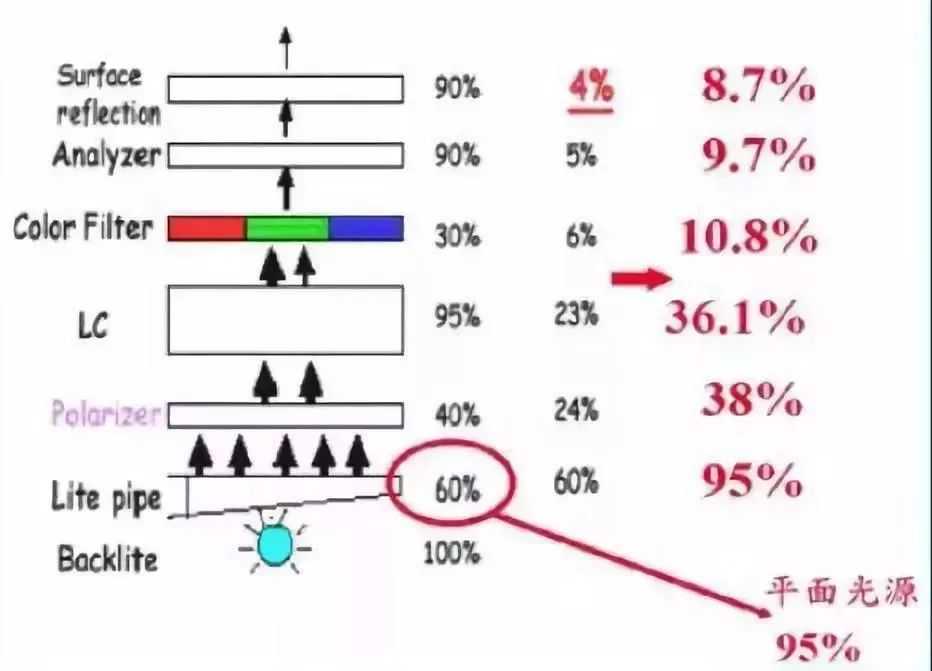

Light loss:According to research, only about 60% of the light emitted from traditional backlight sources passes through the reflective film, diffusion film, and other optical films to enter the polarizing film, and finally, only 4% of the light remains after passing through the LC and surface.Therefore, the design of backlight and the selection of materials are crucial.

LED Backlight Sources and Emission Principles

LED (Light Emitting Diode) is a type of semiconductor solid-state light-emitting device.It utilizes solid semiconductor chips as the light-emitting material, where excess energy is released as photons through the recombination of carriers in the semiconductor, emitting red, yellow, blue, green, cyan, orange, purple, and white light directly.

The core part of the light-emitting diode consists of a chip made of P-type and N-type semiconductors, with a transition layer between the P-type and N-type semiconductors, known as the PN junction.In certain semiconductor materials’ PN junctions, when injected minority carriers recombine with majority carriers, excess energy is released in the form of light, thus converting electrical energy directly into light energy.The PN junction does not emit light when a reverse voltage is applied, making it difficult for minority carriers to inject.

What is Mini LED?

As the name suggests, “Mini” in Chinese means “miniature”.If small-pitch LED displays focus on the “small” between pixel distances, then Mini LED naturally reaches a smaller level, truly qualifying as miniature.If we trace back, we will find that the term Mini LED originated from Crystal Display, which has recently revealed information about the “mass production” progress of Mini LED.

The concept of Mini LED was first proposed by Crystal Display, and it has gradually been accepted by manufacturers on the mainland, although the Mini LED referred to by both parties is slightly different.

Specifically, the “Mini LED” referred to in the industry differs from “Mini LED display”.The Mini LED proposed by Taiwanese manufacturers purely refers to the spacing of crystalline particles, while the Mini LED introduced by mainland LED display industry emphasizes a different packaging form.One refers to a type of new packaging form product, while the other refers to a classification of displays.

Mini LED has two main applications in displays: one is as self-emitting LED displays, similar to small-pitch LEDs; due to the packaging form not requiring wire bonding, Mini LED can achieve smaller pixel pitch displays even with the same chip size compared to small-pitch LEDs.The other application is in backlighting.Compared to traditional backlight LED modules, Mini LED backlight modules will use a denser arrangement of chips to reduce the mixing distance, achieving ultra-thin light source modules.Additionally, combined with local dimming control, Mini LED will offer better contrast and HDR display effects.

Due to the size and packaging technology limitations of Mini LED chips, the current pixel pitch limit for RGB self-emitting display applications is approximately 0.5 mm. When made into a 4K screen, the entire screen size reaches over 85 inches, and the large number of LED chips (~24 million) makes the cost of the screen exceptionally high. To enhance the competitiveness of LEDs in the display market and improve the display quality of existing LCD backlights, the application of Mini LED in the backlight field (hereinafter referred to as Mini BLU) has increasingly attracted industry attention and is often compared with AMOLED.

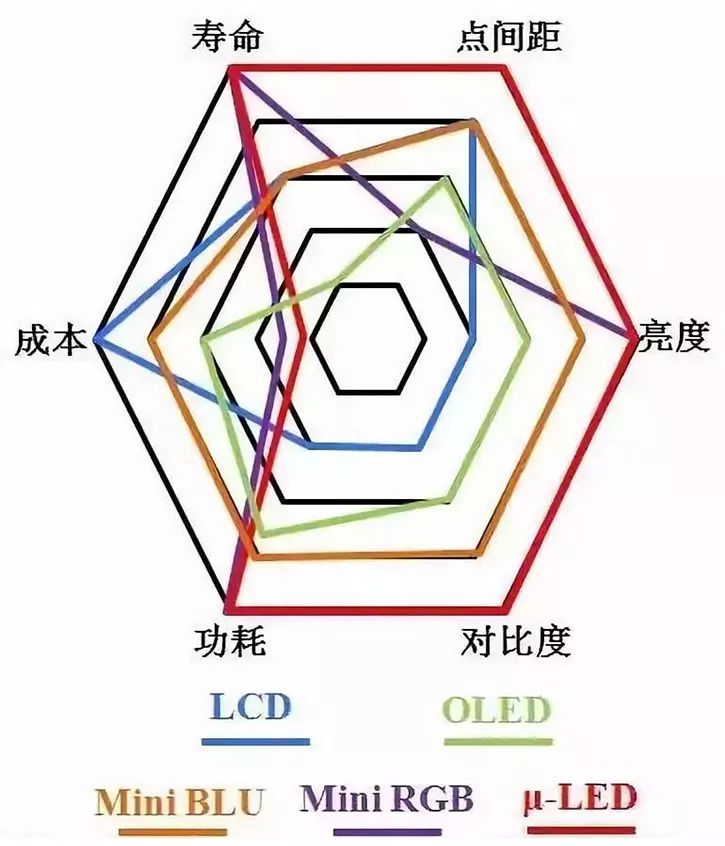

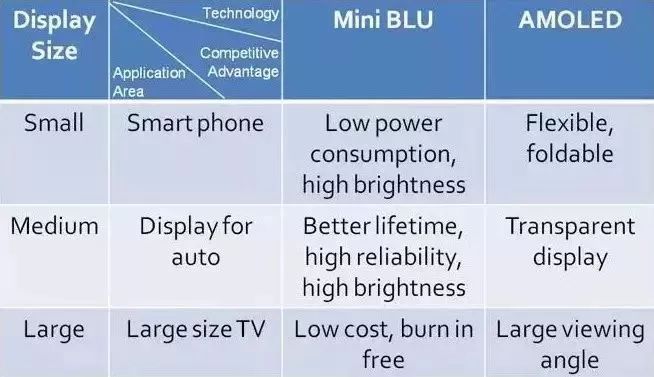

The comparison of Mini BLU with several other display technologies is illustrated in the following figure.In terms of basic elements of display including power consumption, cost, lifespan, pixel pitch, brightness, and contrast, Mini LED is essentially an all-rounder.However, in the current landscape where AMOLED has already gained significant popularity, products applying Mini LED in the backlight field are still under scrutiny and have yet to enter the market.This is primarily due to the relatively late technological reserves of Mini BLU (mainly starting in the second half of 2017) and partly because it still relies on LCD display technology.Even practitioners of LED chips may understandably assume that its display effect will not be as good as AMOLED, hesitantly positioning it below AMOLED.

But the reality is otherwise.Compared to AMOLED, Mini BLU undoubtedly has advantages in cost and lifespan.Due to LED chips having higher optoelectronic conversion efficiency than OLEDs, along with local dimming control, Mini BLU can achieve comparable or even lower power consumption, thus achieving higher contrast and brightness.Pixel pitch is mainly limited by LCD technology, and it can currently outperform self-emitting AMOLED.

Based on these advantages, Mini BLU will always find its place in suitable fields; regardless of whether AMOLED suffers from production capacity shortages, it is certainly reliable.Of course, in today’s consumer market that increasingly pursues personalization, Mini BLU has a fatal weakness: it cannot be made flexible (though it can still be made curved), which is primarily due to limitations of LCD technology.

In terminal applications, from small screens like mobile phones and tablets to medium screens like automotive displays and monitors, and large screens like TVs, Mini BLU and AMOLED each have their competitive advantages, and for the time being, neither can completely replace the other.Especially in automotive and medium-to-large screen displays, Mini BLU will have more evident cost advantages as well as better lifespan and reliability, which are currently irreplaceable advantages for AMOLED.

Mini LED Backlight Technology

Compared to traditional LED backlight sources, Mini LED has more advantages, suitable for high-end LCD display solutions:

1. It can directly adopt RGB three-color LED modules to achieve a display effect without loss of RGB primary colors, covering 100% of the BT2020 wide color gamut, with color vibrancy comparable to OLED.

2. Mini LED can achieve uniform heat dissipation at high brightness (>1000nit), which is unattainable with traditional discrete LED solutions.

3. Mini LED backlight can achieve ultra-thin direct-lit LCD displays, with OD≈0mm, which has broad applications in lightweight portable consumer electronics, such as AR/VR glasses, mobile phones, and laptops.

4. Mini LED, combined with fine local dimming, can achieve ultra-high contrast (1000000:1), making blacks deeper and whites brighter.

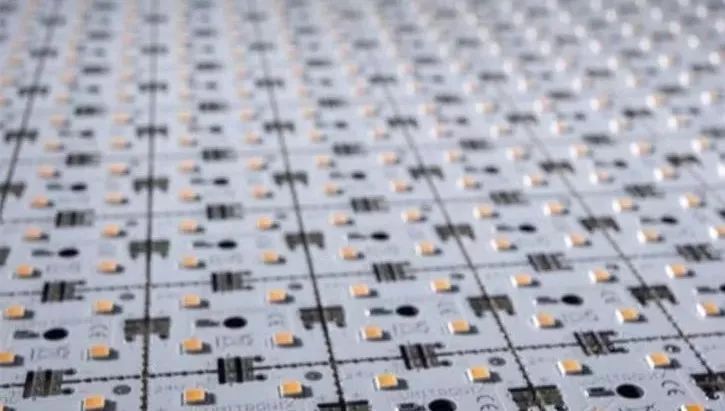

The Mini LED backlight packaging uses flip-chip Mini LED chips to achieve uniform light mixing without the need for lenses for secondary optical design. Due to the small chip structure itself, it is conducive to making the number of local dimming zones more detailed, thereby achieving a higher dynamic range (HDR) and higher contrast effects; on the other hand, it can also shorten the optical mixing distance (OD) to reduce the overall thickness, achieving ultra-thin designs.

Mini LED backlight can combine local dimming technology to control the switch and brightness adjustment of corresponding backlight areas in real-time according to the brightness and darkness of the images in the TV signal, making blacks darker, whites whiter, and colors more natural and vivid, providing the best immersive experience.

▲ During CES 2019, ASUS unveiled its new flagship professional display “ProArt Studio PA32UCX”, a 32-inch Mini LED backlit 4K gaming LCD display, with its BLU using over 10,000 Mini LEDs produced by Longda Electronics.

Mini LED Technology Challenges and Market Applications, Trends

Following Apple’s decision not to use Micro LED in the new generation iWatch, opinions on its technology and applications have become more rational, and related manufacturers are actively collaborating to advance towards application.

Meanwhile, Mini LED has gradually entered reality, with manufacturers following suit. After a year of trials, major terminal application manufacturers have basically completed prototype designs. Recent exhibitions have shown that manufacturers like Samsung and Lumens have introduced Mini LED applications.

However, whether it is the Mini LED products from mainland manufacturers or the Mini LED displays referred to by Taiwanese manufacturers, discussions about both cannot avoid Micro LED.

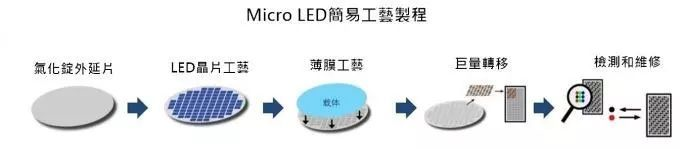

Micro LED is considered the next generation of display products, and it does have its own advantages compared to current LCD and OLED technologies. However, it is well known that Micro LED has not yet achieved substantial breakthroughs in the crucial “mass transfer” stage and key equipment.Moving millions or even tens of millions of micron-level LED crystals correctly and efficiently onto circuit substrates is a massive challenge currently faced by Micro LED.

The industry generally believes that Micro LED will take at least two to three more years to break through the bottleneck of mass production.However, the development of display technology is very rapid, and in the face of the strong rise of OLED, some companies developing Micro LED are watching with concern and urgency.Once OLED gains the upper hand and captures a significant market share, even if Micro LED can overcome technical difficulties in a few years, it may be too late.

In other words, no matter how good Micro LED is, it ultimately cannot quench immediate thirst. In light of this situation, related manufacturers are certainly not going to sit idly by, and thus began to seek a compromise route.It is in this urgent context that Mini LED, regarded as a transitional technology route, has emerged.Mini LED generally refers to LED chips with a size of 50-100 microns.Compared to Micro LED, Mini LED is much more feasible in terms of processing, with lower technical difficulty, making mass production easier and allowing for rapid market entry.

Compared to current conventional applications, Mini LED indeed has its unique advantages:

(1) For backlight applications, Mini LED generally adopts a direct-lit design, utilizing a large number of densely packed chips to achieve localized dimming within a smaller range. Compared to traditional backlight designs, it can achieve better brightness uniformity and higher color contrast within a smaller mixing distance, leading to ultra-thin, high-color-rendering, and energy-saving terminal products.

Additionally, due to its design, it can be paired with flexible substrates, enabling curved displays similar to OLED while ensuring image quality. On the other hand, since OLEDs are self-emitting organic materials, Mini LED also has significant advantages in reliability; based on the mature industrial chain of LEDs, the cost of Mini LED backlights is only about 60% of that of OLEDs of the same size, making it highly competitive across various aspects.

(2) For display applications, RGB Mini LED overcomes the wiring and reliability defects of surface-mounted chips, and combined with the advantages of COB packaging, it makes it possible to further reduce pixel pitch, significantly enhancing the visual effect of terminal products while drastically reducing viewing distances, allowing indoor displays to further replace existing LCD markets.

On the other hand, the use of RGB Mini LED with flexible substrates can also achieve high-quality curved display effects. Coupled with its self-emitting characteristics, it has a vast market in special shape requirements (such as automotive displays).

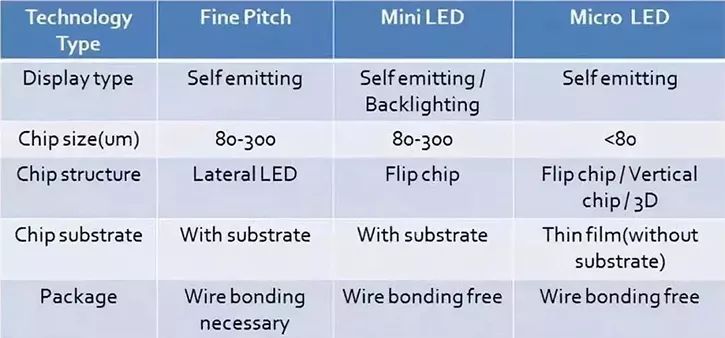

As can be seen, Mini LED has significant advantages over other competitors in the current LED landscape, and based on this, manufacturers are actively researching. Currently, although its chip size is similar to that of small-pitch chips, there are many differences.

Its technology has the following characteristics and challenges:

1. Chip Side

a. Chip miniaturization: Since Mini LED requires pixel pitch to be below 1mm, this requires Mini LED chips to be smaller, with current Mini LED chips generally required to be below 200um. This poses higher demands on photolithography and etching during the production process of LED chips, especially since existing mature production equipment struggles to meet the requirements for producing chips below 100um. In the case of small-sized chips, the flatness of the soldering surface, the design of the electrode structure, solderability, adaptability to soldering parameters, and packaging tolerance are all critical challenges in chip design.Moreover, Mini LED chips currently adopt a low-efficiency full-measurement full-separation mode during production, which poses efficiency issues in processing a large number of high-density, high-precision chips, increasing the cost of Mini LED chips.

b. Red flip-chip: Since flip-chip structures do not require wire bonding, they are suitable for the dense requirements of Mini LED. Therefore, all current Mini LEDs adopt flip-chip structures, while blue and green flip-chip LED chip production is relatively mature. However, the technology difficulty for red flip-chip LED chips is high, requiring substrate transfer, and the production yield and reliability during the transfer process are still not high.

c. Consistency and reliability: As display chips, Mini LED chips have high requirements for product consistency and reliability. Key indicators of consistency include small current consistency, consistency under different currents, high-low consistency, color uniformity, and small and consistent capacitance. Due to the complex usage environments of Mini LED displays and the high difficulty of maintenance, this places high reliability demands on Mini LED chips. Overall, Mini LED chip manufacturers must implement strict production controls to ensure the stability of various indicators.

2. Packaging Side

a. High-efficiency die bonding and placement: Since the chip size of Mini LED is mainly 50-200um, and the unit area usage of Mini LED chips and lamps is massive and tightly packed, this places higher demands on the flatness of the soldering surface and line precision, as well as stricter requirements for soldering parameter adaptability and packaging tolerance. Therefore, achieving high efficiency and high precision in Mini LED chip bonding poses a challenge.Traditional solder paste bonding can lead to chip soldering drift and increased hole rates, failing to meet the high precision bonding requirements of Mini LEDs. Higher precision bonding substrates and bonding equipment are urgently needed solutions.Traditional placement machines must reduce the placement speed to 30-50% of their original speed when placing Mini LED packaging devices below P1.0 due to precision requirements below 25um, significantly reducing the manufacturing efficiency of displays. More efficient placement machines are one of the major challenges that Mini LED will face in the future.

b. Thin packaging: Mini LEDs, when used as backlights, require products to be as thin as possible. However, when the PCB thickness is below 0.4mm, during reflow soldering and molding processes, differences in thermal expansion coefficients between resin substrates and copper layers can induce chip cold soldering. Additionally, during the molding packaging process, differences in thermal expansion coefficients between packaging adhesives and PCBs can lead to adhesive cracking.

c. Light mixing consistency: Variations in light color or circuit issues can cause differences in display or backlight effects, adversely affecting the display quality of Mini LEDs.

d. Reliability and yield: The operating environment for Mini LED displays is relatively complex. If moisture in the air penetrates through packaging materials or supports and contacts the LED chip’s electrodes, it can easily cause short circuits and other issues. Moreover, as Mini LED products are densely packed, the number of packaging devices used increases exponentially, necessitating that Mini LED packaging devices possess relatively high reliability due to the high maintenance difficulty and cost.

3. Driver ICs

a. Current control and heat dissipation: As the pixel pitch of Mini LEDs decreases, the number of LED chips used increases, and chip sizes decrease, leading to smaller driving currents. This makes precise current control by driver ICs increasingly challenging. Future designs will require new circuit designs for precise control of small currents. Additionally, the use of numerous driver ICs and LED chips makes rapid heat dissipation on PCBs difficult, and excess heat can cause color shifting in driver IC modules. Thus, high-integration and low-power driver ICs will be the development direction for display screen driver ICs.

b. Local dimming: For backlight applications of Mini LEDs, current static dimming technologies are difficult to meet the new Mini LED backlight technology requirements due to the high costs of driver circuits requiring numerous ICs in series, the large number of I/O controls, and the large volume of driver circuits. The refresh rate of backlighting is low and prone to flicker. Therefore, driver ICs for local dimming can compensate for the shortcomings of static dimming, but implementing local dimming solutions still faces challenges in improving brightness uniformity and consistency, refresh rates, backlight efficiency, high integration, and fine dimming resolution.

4. PCB Backplane

Under the premise of Mini LED miniaturization, the high requirements for display and backlight effects pose new challenges for the processing precision of PCB backplane thickness uniformity, flatness, and alignment. Additionally, since the PCB backplane contains numerous LED chips and driver ICs, the Tg point must exceed 220°C. During the Mini LED processing, the backplane must withstand various external forces, requiring high tear strength, moisture resistance, and other physical properties to maintain the uniformity of thickness and dimensional stability of the backplane.

To expand the application of Mini LED, upstream and downstream manufacturers in the Mini LED industry are actively working on new technologies and cost reductions. Currently, domestic and foreign Mini LED manufacturers focus on developing or expanding new technologies, including light output adjustment chips, COB and IMD packaging, Mini LED mass transfer, TFT circuit backplanes, and flexible substrates.

1. Light output adjustment chips: When Mini LED is used as a backlight, it often employs a large number of LED chips as direct-lit backlight sources. To adjust the chip output for easier ultra-thin design, Huacan Optoelectronics adds optimized layers to traditional backlight chips to enhance the chip output angle, thereby improving the uniformity of LED chip output and effectively enhancing display effects.

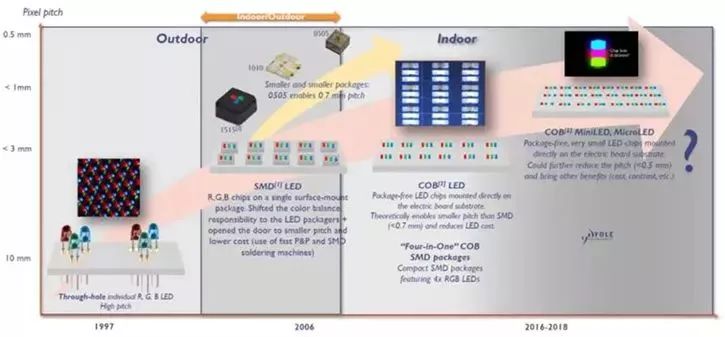

2. COB and IMD packaging: Currently, COB (Chip-On-Board) packaging directly encapsulates LED bare chips onto the module substrate and then performs overall molding. Compared to traditional SMD packaging, this COB packaging of full-color LED modules features fewer manufacturing process steps, lower packaging costs, higher packaging integration, better reliability of displays, and more uniform and delicate display effects, making it a promising important packaging form for future high-density LED display modules.

However, since the COB industrial chain has not yet been fully established, the cost per unit area of COB products is higher than that of SMD. In the future, as the COB display packaging industrial chain matures, the market share of COB display packaging will rapidly increase. In Mini LED applications, COB packaging has higher reliability and stability, making it easier to achieve ultra-small pitch displays, aligning with the technological trends of Mini LED; thus, COB packaging is one of the technological trends for Mini LED.

3. Mini LED mass transfer: Compared to the mass transfer technology of Micro LED, the chip size of Mini LED is larger, making the transfer difficulty relatively lower. Combining mass transfer and COB packaging technologies can effectively improve the production cycle of Mini LEDs. Currently, Uniqarta’s laser transfer technology can transfer approximately 14 million pieces of 130×160 micron LED chips per hour using single or multiple laser beams.

4. TFT backplane: To compete with OLED in terms of image display effects, Mini LED backlight + LCD must achieve top-level HDR, meaning that the number of local dimming zones must reach hundreds or even thousands to be sufficient. However, if driven by traditional LED backlight circuit architectures, this idea may sacrifice cost and slim design due to excessive component usage. In light of this, Innolux proposed using active matrix TFT circuits to drive the AM Mini LED architecture.

5. Flexible substrates: Mini LED backlights generally adopt direct-lit designs, utilizing a large number of densely packed chips to achieve localized dimming. Due to its design, it can be paired with flexible substrates, enabling LCDs to achieve curved displays similar to OLED while ensuring image quality. However, due to the large number of Mini LEDs generating significant heat, developing flexible substrates with high heat resistance will also be a future technological trend.

Market Applications and Trends of Mini LED

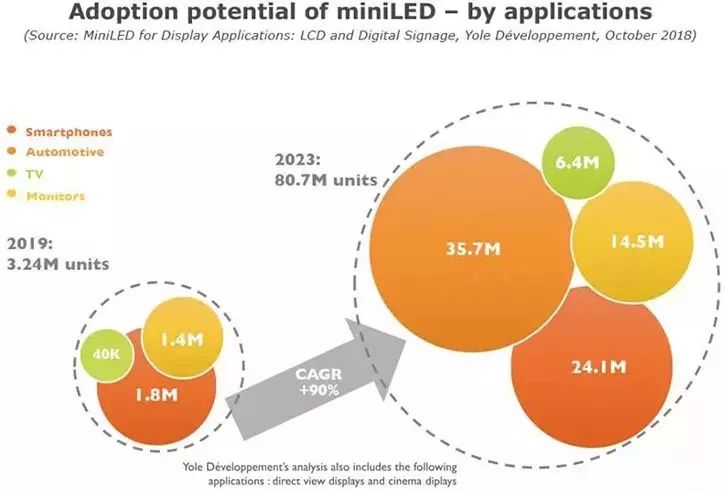

In terms of market applications, the application of Mini LED will inevitably cover part of the current small-pitch LED display market.From the relevant information released by major companies regarding Mini LED, we can see that its applications mainly focus on two directions:one is the LED display market; the other is the backlight application market.

According to GGII’s prediction, the market size for Mini LED applications is expected to reach 500 million yuan in 2018.Among them, mobile phone backlighting will become the vanguard of Mini LED applications. As costs decrease, Mini LED will gradually penetrate into display and medium-to-large size backlighting.

For small-pitch LED displays, the clear target naturally points to commercial indoor applications.Currently, small-pitch LED displays are continuously expanding in this field. However, as the pixel pitch of small-pitch LED displays continues to shrink, they face numerous challenges. Due to inherent issues, the technological process and cost may reach a bottleneck.

Faced with a commercial display market worth hundreds of billions, if some of the problems with small-pitch LED displays cannot be effectively resolved, their hard-earned advantages in competing with LCD, DLP, or OLED display products may gradually diminish, or at least restrict the further expansion of small-pitch LED displays in the commercial display market.

In this context, whether companies launch COB small-pitch displays or Mini LEDs, their original intention is to better address the current challenges faced by small-pitch LED displays.

The backlight application market also holds vast development prospects for Mini LED.According to TrendForce’s estimates, as the next generation of backlight technology, Mini LED is expected to reach an overall output value of 1 billion USD by 2023.Moreover, due to limited production capacity of OLED panels, Mini LED is expected to be first applied in well-known consumer electronics terminals like Huawei, OPPO, and VIVO in 2018.

In the LED display field, we have yet to see actual application cases of Mini LED, but some companies have stated that Mini LED has already received customer orders and is currently shipping, with expected application cases to emerge by the end of September.So what impact will Mini LED have on LED displays once it starts large-scale application?

For Mini LED, some view it as a product transitioning LED displays towards Micro LED, while others hold differing opinions, believing Mini LED is not merely a transitional technology but has a long lifecycle.After all, the trend of shrinking pixel pitch in LED displays is quite evident, but as small-pitch LED displays develop below P1.0, they indeed face severe challenges in technology and cost, and the pain points of small-pitch LED displays undoubtedly present significant opportunities for Mini LED.With the promotion of both display and backlight technological applications, the future of Mini LED looks promising, which is also a key reason for its popularity among Taiwanese and mainland manufacturers.

Indeed, while Mini LED is promising and has a broad market outlook, we should not overly exaggerate its influence on LED displays.From the current development status, small-pitch LED displays have not yet reached an insurmountable bottleneck, and there remains ample room for technical optimization, as well as potential for further cost reduction.Moreover, small-pitch LED displays are still in a rapid development phase.

High-end LCD Displays Leading the Push for Mini LED Applications

In terms of smartphone applications, Mini LED faces the formidable strength of OLED, as the cost-performance ratio of OLED has already positioned it favorably in the high-end/flagship niche market.With the dramatic increase in the number of OLED suppliers and global production capacity expected in the next five years, OLED costs will continue to decline, and its market share is anticipated to further increase, gradually dominating the market.

However, Mini LED has the potential to shine in various medium and small-sized high-value-added display fields, where the weaknesses of OLED, such as cost, availability, and longevity issues (like burn-in or image retention), still need to be resolved.In tablets, laptops, and high-end displays used for gaming applications, Mini LED can deliver excellent contrast, high brightness, and a slim profile at a lower cost than OLED.

The automotive segment is particularly attractive, primarily due to the strong growth potential in quantity and revenue, as well as Mini LED’s ability to meet various requirements desired by automakers:extremely high contrast and brightness, longevity, adaptability to curves, and durability.

Regarding the last point of durability, Mini LED offers significant advantages over OLED, as it utilizes proven technologies with LED backlights and liquid crystal units, which bear little difference from mature LCDs.Thus, automakers do not need to take risks and hope that new technologies can meet their stringent requirements for longevity, environmental conditions, and operating temperatures.

In the television sector, Mini LED can help LCDs bridge the gap and regain market share in high-end, large-size, high-profit segments above 65 inches from OLED.For panel and display manufacturers who have not invested in OLED technology, this opportunity is particularly appealing, as it allows them to extend the lifespan and profitability of their LCD factories and technologies.

Direct View LED Technology

For direct view LED displays, Mini LED combined with Chip-On-Board (COB) architecture can achieve higher penetration rates of narrow pixel pitch LED displays across various applications, thereby expanding the addressable market.Chip sizes will continue to decrease, potentially down to 30-50um, to further reduce costs.The application in cinemas still has high uncertainty, but even slight adoption will present significant growth opportunities.

Market Size Forecast for Mini LED by Application from 2019 to 2023

Incremental Innovation and Limited Investment Amid Supply Chain Disruptions

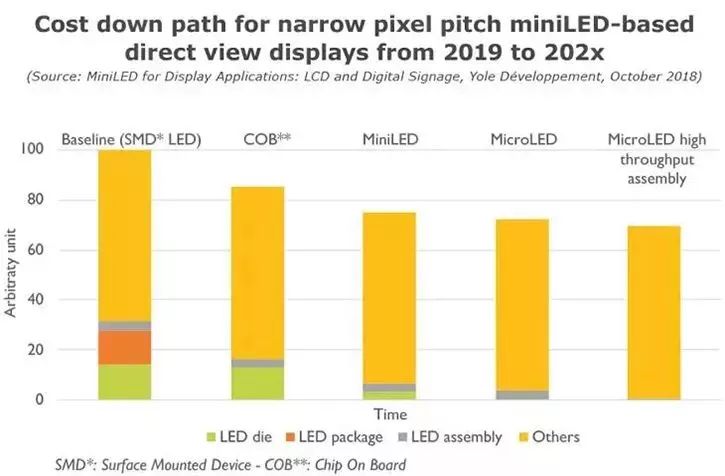

Unlike Micro LED, which requires substantial investments, Mini LED can be produced by established LED chip manufacturers in existing wafer fabs without any major investments.However, they may potentially displace LED packaging factories from the supply chains of LCDs and large LED video wall digital signage, causing significant disruptions.For many major LED packaging manufacturers, these applications represent a significant portion of their revenue.

Manufacturers facing early exposure to these issues are rapidly responding by moving up the supply chain and providing complete Mini LED backlight modules (such as Refond and Lextar), or by developing new innovative packaging to continue riding the wave of the Mini LED trend.For instance, new “4-in-1” surface-mounted devices (SMD) packaging from companies like Harvatek or Nationstar helps LED direct view display manufacturers overcome key barriers to Mini LED applications:the need to update equipment and transition from SMD to direct chip bonding assembly.

Mini LED should benefit chip manufacturers by expanding their available markets.Some manufacturers are attempting to seize market opportunities and upgrade their supply chains by offering Mini LED packaging and/or BLU modules.For example, Epistar is spinning off while still controlling its Mini LED business.

The remaining question is how quickly equipment manufacturers can develop the next generation of Mini LED-specific assembly equipment, which will help accelerate Mini LED applications by lowering manufacturing costs.The key requirements for these devices are higher throughput and the ability to handle chips of 100um and smaller.

The first to enter the market is Kulicke & Soffa, which recently launched equipment developed in collaboration with startup Rohinni.

Efficient processing of smaller chips will enable LCD and LED direct view display manufacturers to reduce chip sizes to the lowest levels for each application, further lowering costs.

Finally, for most target segments, the performance offered by miniLED is already close to that of existing technologies, such as OLED for high-end consumer displays and SMD LED for narrow pitch digital signage.Therefore, cost will be the main factor hindering or promoting miniLED applications.

Cost Reduction Paths for Narrow Pixel Pitch Mini LED Direct View Displays from 2019 to 202x

Overall, Mini LED currently has advantages over OLED in terms of cost, brightness, energy consumption, and product lifespan in the backlight field, but its impact on LED displays is still quite limited.Only when Mini LED matures and enters the market on a large scale will it create a collision with current display products and pose challenges.

Source:Optoelectronics and Display