Heat Shrink Tubing Kits for DIY Robotics and Automation Projects

The fun of robotics and automation work can quickly become dull due to loose connections. Frustrating? Absolutely frustrating. However, such issues are common in DIY robotics and automation projects. Fortunately, there is a simple solution—heat shrink tubing.

Heat shrink tubing kits can make a significant difference. They help protect your components, reduce troubleshooting hassles, and give your project a clean, professional finish. Read this article to understand why heat shrink tubing kits are essential for anyone involved in robotics and automation work.

Wiring Challenges in DIY Robotics/Automation

Wiring is often one of the most tedious and error-prone aspects of electronic projects. It’s not just about connecting components; it’s also about ensuring connections are secure, organized, and easy to maintain.

Traditional electrical tape is not a long-term solution for protecting, insulating, and identifying wires. Unprotected wires and cables may require frequent repairs and replacements. Additionally, whether it’s a sensor failure or an unresponsive actuator, messy wiring increases troubleshooting time.

What is a Heat Shrink Tubing Kit? What are its Advantages?

Heat shrink tubing is a thermoplastic cylindrical protector, insulator, and identifier suitable for wires, cables, joints, connectors, and other electrical components. Heat shrink tubing comes in single-wall and double-wall types, with the shrink ratio referring to the reduction in size of the tubing relative to its original size after heating. The most common shrink ratios are 2:1 and 3:1, meaning the tubing shrinks to half and one-third of its original size, respectively. Heat shrink tubing with adhesive lining provides additional protection against environmental factors.

Main Advantages:

Ⅰ. Wire insulation and protection

Ⅱ. Organization and cable management

Ⅲ. Stress relief and durability

Ⅳ. Professional surface finish

Ⅴ. Waterproof options with adhesive

Practical Applications in DIY Robotics and Automation

Heat shrink tubing is not only versatile but also nearly essential for various DIY projects. Here’s how to effectively use it in different applications:

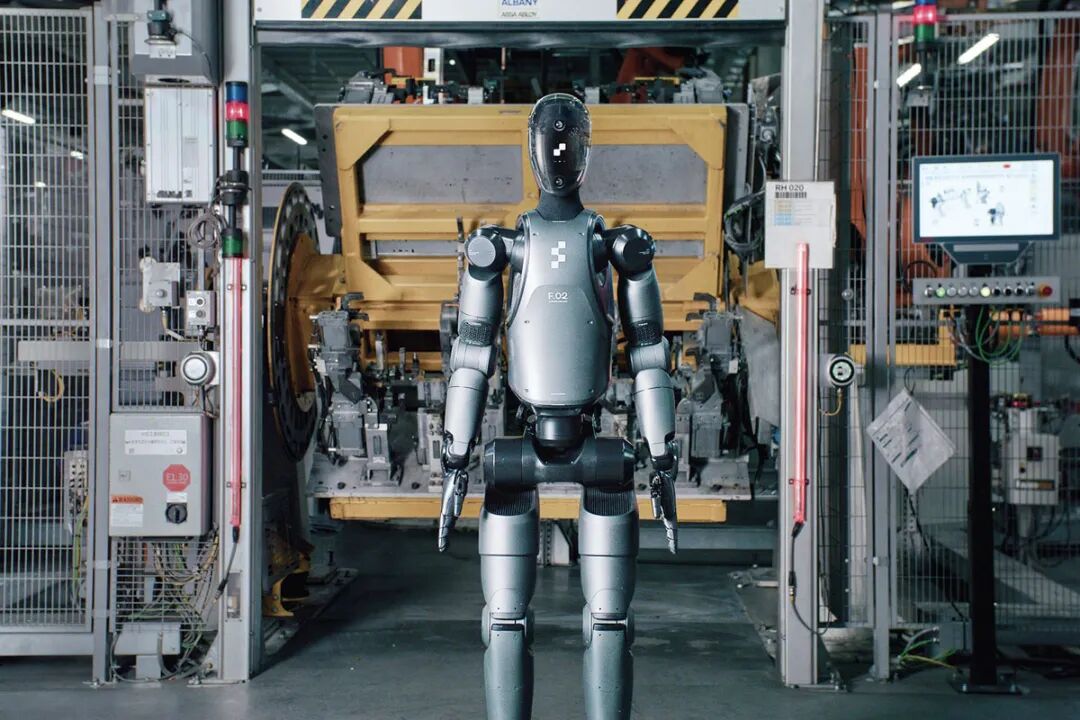

Robotics:

Ⅰ. Protect motor connections

Ⅱ. Organize wiring for sensors and actuators

Ⅲ. Form durable wire harnesses

3D Printing:

Ⅰ. Secure, protect, and insulate hot end wiring

Ⅱ. Manage cable routing for stepper motors

Ⅲ. Enhance the overall aesthetics of the printer

Home Automation:

Ⅰ. Protect connections in custom lighting projects

Ⅱ. Organize wiring for sensor networks

Ⅲ. Ensure reliable connections with custom controllers

Drones:

Ⅰ. Protect connections on flight controllers

Ⅱ. Keep wiring organized in tight spaces

Ⅲ. Provide moisture protection for connections during outdoor flights

Step-by-Step Guide: Effectively Using Heat Shrink Tubing Kits

Here’s a simple step-by-step guide to help you make the most of your heat shrink tubing kit:

1. Choose the right tubing: Select tubing with a diameter suitable for your wires. For waterproofing, choose heat shrink tubing with adhesive.

2. Prepare the wires: Strip the outer insulation from the wires and make necessary connections (e.g., soldering). Ensure connections are secure before proceeding.

3. Slide on the tubing: Place the tubing over the wire or connector before heating.

4. Heat: Use a heat gun, lighter, or other heat source to evenly shrink the tubing. Handle with care to avoid overheating.

5. Finish precisely: Ensure the tubing adheres tightly to the wire for optimal results.

Tips and Tricks:

Ⅰ. Use a heat shrink label maker for a personalized, professional look.

Ⅱ. Wear heat-resistant gloves for safety.

Ⅲ. Avoid open flames, as they can overheat the tubing and compromise its integrity.

Ⅳ. For long wires, slide all necessary tubing into place before making connections.

Choosing the Right Heat Shrink Tubing Kit

When selecting a heat shrink tubing kit, the G-APEX heat shrink tubing set offers exceptional quality and durability to meet the needs of any robotics and automation project. We provide a variety of sizes, colors, and adhesives to create the professional-grade experience you desire.

Double-wall tubing can form a barrier against liquids and moisture, preventing corrosion. This tubing kit offers a shrink ratio of up to 4:1, with a temperature range of -40 °C to 130 °C (-40 °F to 266 °F), providing excellent protection.

Incorporating Heat Shrink Tubing into Your Robotics and Automation Projects

G-APEX offers heat shrink tubing in various colors and packaging sizes to meet your robotics and automation needs. Integrate the G-APEX heat shrink tubing kit into your next project.

This article is originally from Dongguan Yunlin, welcome to follow for more knowledge!