Source:China and Foreign Highways, Asphalt Pavements

Recommended Read: Micro Civil Engineer, welcome to submit!

【Abstract】 With the continuous increase in the total mileage of roads in China, the repair of road surface disasters has become increasingly important for the operation of the transportation system. However, traditional road repair methods require long traffic control times, which can easily cause traffic congestion and even lead to accidents and casualties. As a new rapid manufacturing technology, 3D printing technology can shorten the time required for road repair projects and avoid significant economic losses. This paper first summarizes several traditional repair methods for cracks and potholes in road surface disasters, analyzing the shortcomings of traditional repair methods; then it outlines the current status of 3D printing technology, introducing the main application technology classifications of 3D printing and its use in the construction field. It focuses on the indirect and direct methods of applying 3D printing technology to road damage maintenance and repair, proposing directions for improvement based on referenced research backgrounds and discussing the development prospects of 3D printing technology.

【Keywords】 3D printing technology | cracks | potholes | road repair projects

With the rapid development of the transportation industry in China, the total mileage of highways has reached the highest in the world[1]. However, the increase in total mileage has also intensified the workload of road repair projects. Traditional road repair methods not only require traffic control to ensure the normal progress of repair work but also necessitate a maintenance period to ensure that the repair materials can gain strength, which is time-consuming, labor-intensive, and inefficient. This calls for a new technology that can quickly and effectively complete road maintenance work while ensuring repair quality.

The development of information technology has driven the national development direction towards intelligence. As a smart manufacturing technology that integrates research results from multiple fields, 3D printing technology has been widely applied in various fields. From the “3D Printing Technology Industry Development Action Plan” to the “Three-Year Action Plan to Enhance the Core Competitiveness of Manufacturing”, the introduction of these policies reflects the country’s emphasis on 3D printing technology. This paper narrates from the perspectives of common road diseases and traditional repair methods, key technologies of 3D printing, applications in construction, and the application of 3D printing in road repair projects, analyzing the application trends of 3D printing technology.

1. Common Road Diseases and Repair Methods

1.1 Common Road Diseases

Modern traffic pavements inevitably bear various loads after being opened to traffic, and after a period of time, some damage and deformation will occur. Nowadays, the traffic volume is increasing, and overloading is common, causing the road surface to bear both static and dynamic loads from the natural environment and vehicles, making it more prone to various road diseases. If damaged areas are not repaired in time, they will bear more impact loads, and the fractured parts will become larger, making repair work increasingly difficult. The most common road diseases are cracks and potholes[2]. Automatic identification of cracks can use image segmentation technology based on a four-stage bounding box[3]. The road surface data collection system can continuously collect 1mm of three-dimensional data of the road surface at high speed, using various sub-fusion algorithms to identify cracks.

1.2 Common Repair Methods for Cracks and Potholes

1.2.1 Crack Repair

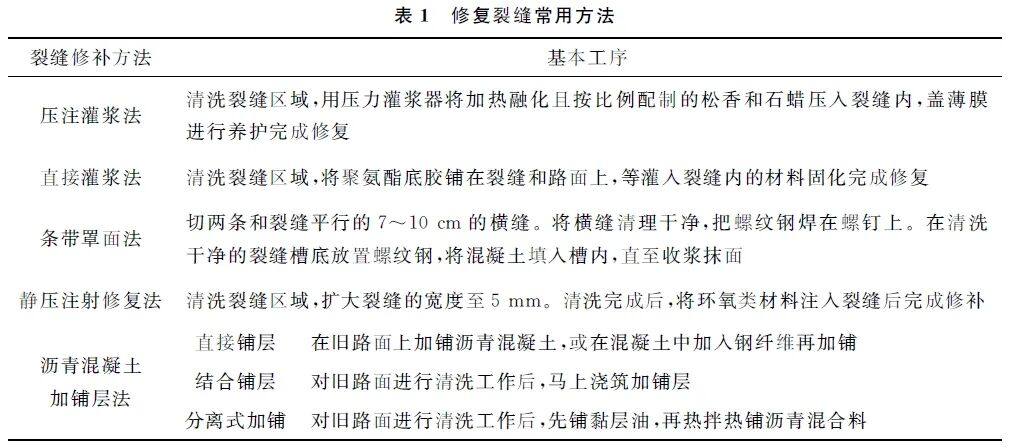

The traditional method for repairing cracks involves initially cleaning the area to be treated with a brush to remove obvious impurities such as dirt and old filler. The cleaning process of the joint groove should not damage the groove mouth. If the bonding surface of the groove mouth is too smooth, an electric saw should be used to roughen the smooth surface to increase the friction of the bonding surface, followed by washing with water to complete the cleaning. After cleaning, compressed air is used to deeply clean dust and other small impurities. The common materials for sealing cracks are hot asphalt or emulsified asphalt, and once cured, the sealing repair process is complete. Common methods for crack repair are shown in Table 1[4].

1.2.2 Pothole Repair

Potholes in asphalt pavements are formed due to the aging and shedding of asphalt[5]. Alternatively, if cracks in the asphalt pavement are not addressed in a timely manner, the asphalt layer may peel under vehicle loads, leading to the formation of potholes. When the bearing capacity of the constructed roadbed is insufficient, potholes can also occur due to uneven settlement of the asphalt pavement[6].

Pothole repair should be based on the depth of the damage. If the damage extends to the roadbed, the pothole should be excavated down to the base, and repair materials should be used to seal the base. Once the base repair is completed, the surface layer can be treated. If the surface layer is completed before the base repair, the load-bearing capacity of the new surface layer will significantly decrease because the foundation of the new surface layer is broken and unstable[7].

Potholes in cement pavements generally form due to transverse joint cracking, causing the slabs to misalign. When two slabs are not at the same elevation, vehicles passing over will cause additional impacts at the misaligned positions. The repeated application of impact loads will cause the edges of the slabs to fracture, leading to the formation of potholes.

The traditional repair method involves cleaning the damaged area thoroughly and then filling the damaged area with new concrete. Additionally, to prevent the damaged area from affecting other areas, the damaged area must be broken up with a cutting machine, cleaned, and then re-poured with concrete. The repaired area cannot be used immediately and must wait for the concrete to complete its hydration reaction to gain strength. During the maintenance period, traffic control is required to prevent vehicles from damaging the repaired area.

1.2.3 Shortcomings of Traditional Methods

(1) Because the repair materials cannot withstand large loads during the repair process, long traffic control is required before strength is formed.

(2) Regardless of the type of material being repaired, a maintenance period is required, during which traffic control is more likely to cause congestion or accidents.

(3) The economic impact caused by traffic control is significant; if cracks appear on critical highways, the impact is even more severe.

Road diseases often occur in areas with heavy vehicle traffic, and if repairs are not timely, the damaged areas will increase. This necessitates a method that can quickly complete repair work to reduce traffic control time and avoid greater losses.

2. 3D Printing Technology

2.1 Overview of 3D Printing Technology

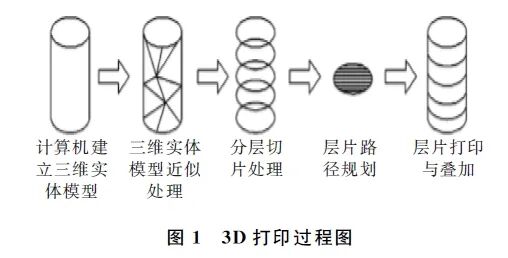

3D printing emerged in the 1990s. The first 3D printing device was created in 1986 by 3D Systems in the United States. 3D printing technology refers to the technology of rapidly printing materials based on digital models[8]. Traditional machining technology involves subtracting material to form products, while 3D printing technology is classified as “additive manufacturing”[9]. As shown in Figure 1.

3D printing technology integrates multiple technologies, achieving the transformation of products from models to entities[10]. Currently, a variety of materials can be used with this technology, and different materials can be applied in different fields. The three-dimensional scanning technology in 3D printing can also help detect the roughness of road surfaces[11], which plays an important role in road maintenance and repair.

2.2 Main Forming Technologies of 3D Printing

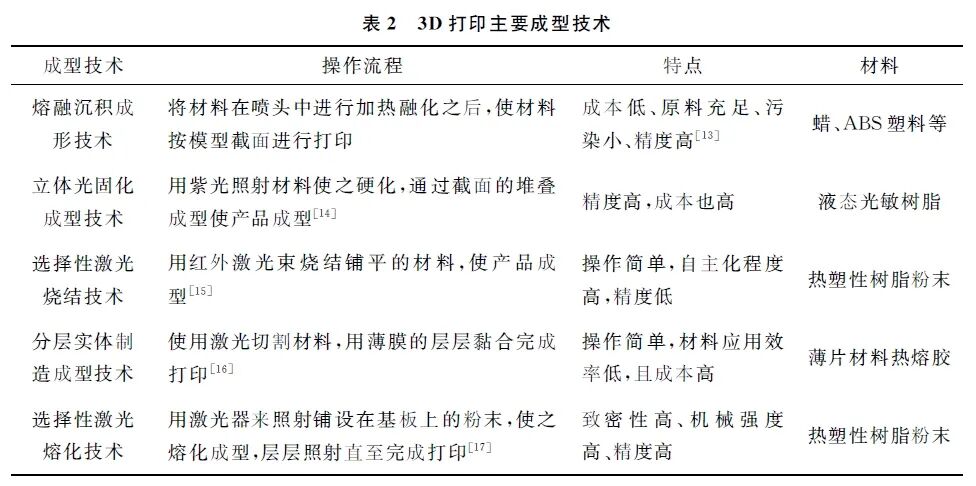

3D printing technology is a fusion of various intelligent technologies. With the development of technology, new materials are constantly emerging, and the combination of the two has given birth to various practical paths for 3D printing technology[12]. As shown in Table 2.

2.3 Applications of 3D Printing Technology in the Construction Field

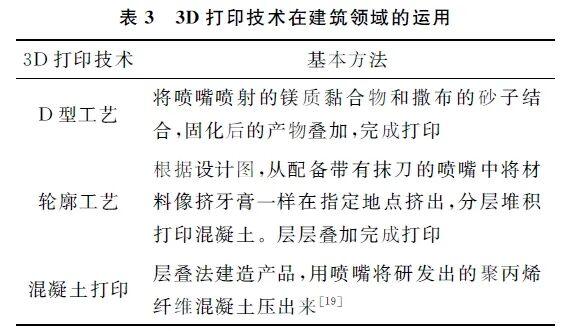

Joseph Pegna[18] was the first scientist to apply 3D printing technology in the construction field. His method involved first laying sand on the base layer and then applying layers of cement in batches for steam curing to complete the printing of building components. The three methods of applying 3D printing technology in construction are shown in Table 3.

3. Application of 3D Printing Technology in Road Repair

3.1 Differences Between 3D Printing and Traditional Methods

Currently, in urban road maintenance construction, traditional repair methods require construction vehicles and maintenance personnel to stay on the damaged road section for extended periods. However, vehicles on highways travel at high speeds, making collisions or scrapes with construction vehicles or maintenance personnel very likely, which can even lead to damage to repair equipment and results, as well as casualties. If a rear-end collision occurs, the losses will be even greater. From 2006 to 2017, there were 178 accidents caused by road maintenance work in Shanghai, resulting in 54 deaths and 106 injuries[20].

Vehicle loads are primarily concentrated on the road surface, so the proportion of diseases occurring on the road surface is the highest, making road maintenance primarily focused on repairing road diseases[21]. To reduce traffic accidents caused by road maintenance, it is essential to minimize traffic control time. Only by accelerating the repair process of road disasters and reducing maintenance time can the accident rate decrease.

The shapes of the most common road diseases, cracks, and potholes are unique, and 3D printing technology can quickly print corresponding repair blocks based on the scanned models in computer software to repair road diseases. By avoiding maintenance time for the repair area on the road, the traffic control time can also be correspondingly reduced. Compared to traditional methods, applying 3D printing in road repair not only saves road maintenance time but also ensures the normal operation of the traffic network near the damaged section. Therefore, how to better integrate 3D printing with road repair is crucial.

3.2 Methods for 3D Printing Repair of Damaged Roads

With the development of intelligent detection equipment, it is now possible to collect information on damaged areas[22]. Through precise identification of diseases by the road management system, traffic agency officials can quickly make decisions regarding the maintenance or repair of road disasters[23]. The combination of three-dimensional optical systems and printing technology can help computers better draw models of damaged areas, and the specific steps are as follows:

(1) The road disease identification module[24] scans the images of the disaster situation through digital image scanning, detecting the type of disaster using an intelligent road detection system.

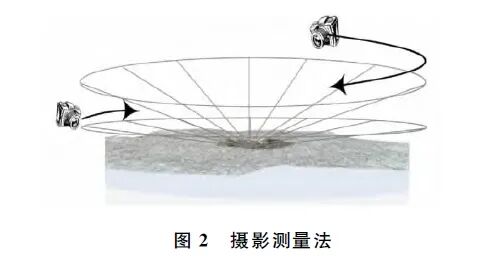

(2) A 3D scanning system measures the three-dimensional elevation of potholes or cracks, forming point cloud data. The point cloud data is stitched together to obtain a three-dimensional coordinate digital model of the disaster pothole or crack. Of course, a more cost-effective photogrammetry method can also be used to collect point clouds, but it results in fewer points and lower precision than a 3D laser scanner.

(3) The 3D printing system can repair the damaged area based on the obtained three-dimensional coordinate digital model in two ways[25]: ① by making molds to prefabricate repair blocks; ② by directly completing the repair work at the crack.

3.2.1 Indirect 3D Printing Repair Method

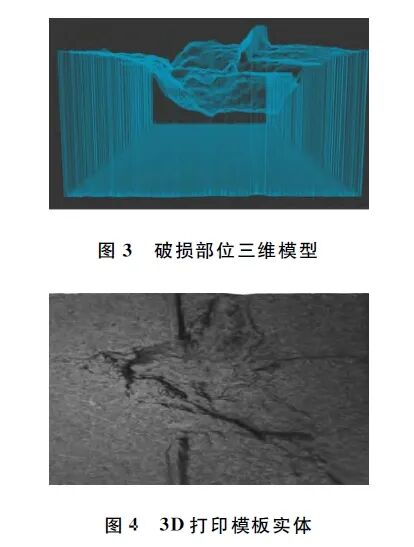

Jaeheum Yeon et al.[26] developed a new type of road repair method using 3D printed repair blocks based on the process of 3D printing teeth. The indirect 3D printing repair method involves prefabricating three-dimensional concrete repair blocks[27] and bonding the repair blocks to the damaged area to complete the repair process. The three-dimensional model of the repair block can be obtained through a three-dimensional laser scanner. The data points obtained from scanning the damaged area are connected to form many triangular surfaces, and combining these surfaces results in a high-precision three-dimensional computer model of the damaged area. Photogrammetry can also perform scanning functions, but it is relatively much cheaper, albeit with lower precision.

If a repair block is to be printed directly, the precision requirement is at least 1mm. Currently, there are two types of printers that can be used for printing construction materials: one is a contour process printer[28], but this printer uses concrete columns approximately 40mm wide and 10mm high to complete the shape printing, which is too low in precision; the other is the D-type process designed by Enrico Dini[29]. It forms the shape of each layer through the combination of adhesive and sand, layer by layer to complete the overall shape. This method can meet the precision requirements, but the combination of sand and adhesive cannot meet the strength requirements, necessitating that the produced repair blocks can withstand normal vehicle loads.

Through a 3D printer, it is possible to choose not to directly print the repair block but to use suitable materials to print molds corresponding to the repair block, completing the prefabrication in the template. The basic steps are:

(1) Clean the damaged area to prevent impurities from affecting the precision of the damaged model.

(2) Use photogrammetry to measure the damaged area. The photogrammetry technique requires taking 12 photos at a certain height of the damaged area, each differing by 30°, and then changing the height to take another 12 photos to capture vertical shape changes, as shown in Figure 2.

(3) Use computer software to create a three-dimensional model of the damaged area, adjusting its size according to the actual situation. Through the 3D printing system, the template is printed based on the three-dimensional model. The three-dimensional model is shown in Figure 3; the template is shown in Figure 4.

(4) Add concrete to the template and cure for 28 days. The shrinkage of concrete is inevitable, so on one hand, the control of temperature and humidity must be precise to minimize shrinkage; on the other hand, the volume of the three-dimensional model should be appropriately enlarged to offset the shrinkage of the concrete.

(5) Use suitable adhesives to connect the prefabricated block to the damaged area. Under the action of the adhesive, only 1 hour of traffic control time is needed to complete the repair process.

3.2.2 Direct 3D Printing Repair Method

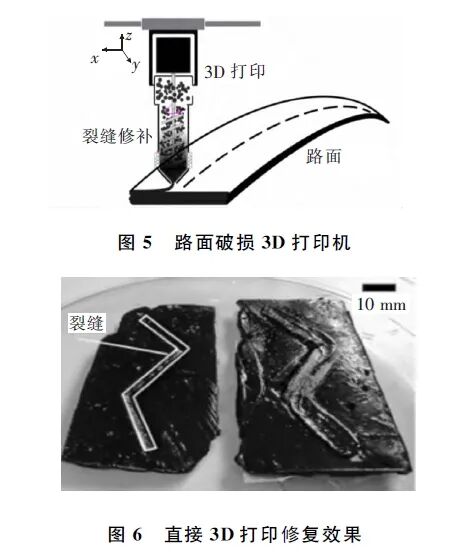

The direct 3D printing repair method has limitations on the number of materials; currently, it can only print one type of material, so direct printing of asphalt mixtures cannot be completed. The printing principle is to extract the three-dimensional profile and attributes of the crack using a laser scanning technology based on Object-Based Image Analysis (OBIA)[30]. The software in the control computer raises the temperature of the thermoresistor, and the asphalt particles are extruded through a screw extruder at high temperatures, with the nozzle injecting the softened asphalt into the crack, completing the repair of the crack. The repair of cracks has high requirements for dimensions and precision, so the nozzle size should not be too large. The 3D printer is shown in Figure 5; the repair effect is shown in Figure 6.

At this stage, the direct 3D printing repair method cannot achieve the application of composite materials, but it can meet high precision requirements. Moreover, the printing process is performed in situ at the damaged area, allowing for direct completion of repair work; the indirect method involves prefabricating repair blocks through printing molds, which has no material restrictions and can be applied to pothole repairs. However, since the prefabrication of repair blocks requires a curing time (28 days), the damaged area may change during this period, and the shrinkage during the hardening process of the prefabricated block may lead to excessive errors, failing to achieve the expected repair effect. To solve this problem, there are two methods: ① first print a plastic repair block and bond it to the damaged area to ensure that the damaged area does not suffer further damage and that the repair block is easy to remove; ② use materials that can cure faster instead of concrete, allowing the prefabricated block to be completed before the damage deforms. Gao Mingyue[32] used square sheet repair blocks made of epoxy resin concrete to achieve rapid pothole repair, as shown in Figure 7.

However, the material cost is significantly higher, and it causes greater damage to the original road structure. Therefore, the method of using 3D printing technology to repair road potholes is more economical and causes less damage to the original road.

3.3 Difficulties and Challenges

The speed of forming with 3D printing technology is fast, which can shorten a 7-day maintenance work to 1-2 hours, significantly reducing traffic control time, and the uniform stability and strength of the repair area can meet the requirements. However, the disadvantages are also evident: 3D printing technology has high material requirements. To better apply 3D printing in road engineering, material development is key. Only by breaking the limitations of materials can 3D technology develop more rapidly.

For cement concrete, under the premise of ensuring strength requirements, it is necessary to minimize curing time[32], find suitable aggregate shapes and maximum particle sizes that meet the requirements of 3D printers while considering the rheological properties of the materials; for asphalt concrete, slow forming and easy segregation hinder the application of 3D printing, so it is necessary to select warm-mix, strong adhesive, and easily solidifying asphalt while considering costs to meet the requirements of the printer. Currently, the cost of printers is high, and their size is small, making widespread application difficult. In the future, it is necessary to further reduce costs, improve precision, and integrate 3D printing with traditional manufacturing technologies to achieve large-scale production, thus enabling better application of 3D printing in road repair.

5. Conclusion

3D printing technology, with its characteristics of material savings, high precision, and three-dimensional model manufacturing, has had a significant impact on the traditional construction industry. Both methods of road damage repair based on 3D printing technology can effectively complete road repair work, greatly reducing traffic control time caused by road repairs, lowering traffic accidents and economic losses caused by road repairs, and alleviating traffic congestion. In the face of the current massive traffic network and the increasing length of roads, road repair work is becoming increasingly heavy. As a rapid repair technology, 3D printing should be applied to road repair projects as soon as possible. Although there are many limitations and shortcomings in 3D printing repair technology, as a new technology that can fundamentally change the traditional road maintenance and repair industry, its application prospects are very broad. At the same time, 3D printing technology is just one type of 3D technology, with others like 3D paving technology. With the development of technology, the application of 3D technology will become increasingly mature, and the fields of application will continue to expand.

(Source: China and Foreign Highways, Asphalt Pavements,Recommended by Micro Civil Engineer)

【Copyright Statement】Currently, “Micro Civil Engineer” is a public welfare WeChat account aimed at providing a platform for online communication for civil engineers. The articles pushed by this account are for learning, communication, and sharing purposes only, with no profit motive, and do not represent the views and positions of this account. Original articles are generally required to be marked as “original” according to the WeChat public platform service agreement; except for articles whose sources cannot be determined, all reprinted articles are marked with the author and source. If you feel that your copyright or other issues are infringed, please contact us for timely deletion. Other online media that reprint articles from this account should also indicate the source! Thank you for your understanding and support! (Micro Civil Engineer)

Welcome to follow “Micro Civil Engineer”!