A metal wound gasket is a high-performance sealing element made of high-quality stainless steel (commonly used materials include SUS304, SUS316) interleaved with flexible filler materials such as graphite, polytetrafluoroethylene, non-asbestos, or asbestos, wound in a spiral. It typically adopts a “V” or “W” shaped steel strip structure, with the starting and ending points fixed by spot welding, forming a structurally stable composite gasket. The basic type of wound gasket has no inner or outer rings and is mainly used for sealing on tongue-and-groove surfaces, flat surfaces, or raised face flanges under medium to low pressure conditions.

Performance Advantages

-

Excellent Sealing Performance: It has good compression and rebound capabilities, forming a multi-layer sealing structure with a certain self-tightening effect;

-

Strong Adaptability: Insensitive to minor defects on the flange sealing surface, avoids bonding, and facilitates disassembly and maintenance;

-

Resistance to Operating Condition Fluctuations: Effectively responds to pressure fluctuations, temperature changes, and mechanical vibrations, suitable for stable sealing under high temperature, low temperature, high vacuum, and alternating load conditions;

-

Long Service Life: Maintains sealing integrity even in harsh environments, reducing maintenance costs.

Typical Applications

Widely used in static sealing connections in industries such as petroleum, chemical, electric power, metallurgy, shipping, nuclear energy, aerospace, textiles, pharmaceuticals, and machinery, such as:

-

Flange connections (pipes, valves, etc.)

-

Pressure vessels, manholes, handholes

-

Sealing parts of equipment such as heat exchangers, condensers, and towers

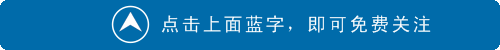

Structure Types and Codes of Wound Gaskets and the Types of Flanges Used:

Basic Type:

With Inner Ring Type:

With Positioning Ring Type:

With Inner Ring and Positioning Ring Type:

Materials:1. Basic Type Wound Metal StripA. Made of cold-rolled steel strips such as SUS304, SUS316L, SUS321 with a thickness of 0.15mm to 0.25mm, or determined through negotiation between the supplier and the buyer.B. The metal strip is a pre-formed narrow strip in a V or W shape, with a smooth and clean surface, free from defects such as roughness, cracks, scratches, pits, and rust spots.C. The hardness value of stainless steel is HV≤200.

2. Basic Type Wound Non-Metal Strip A Non-metal fillers include specially made asbestos strips, flexible graphite strips, polytetrafluoroethylene strips, non-asbestos fiber strips, and mica strips. The thickness of the strips is 0.3-1.0mm.B. The loss on ignition of specially made asbestos must be ≤25%.C. The chloride ion content of non-metal strips must be ≤100PPM.D. The recommended temperature and pressure for various media and non-metal strips are as follows:

Main Technical Parameters of Various Non-Metal Materials for Wound Gaskets:

The following table is for selecting materials for the inner ring and wound metal strip:

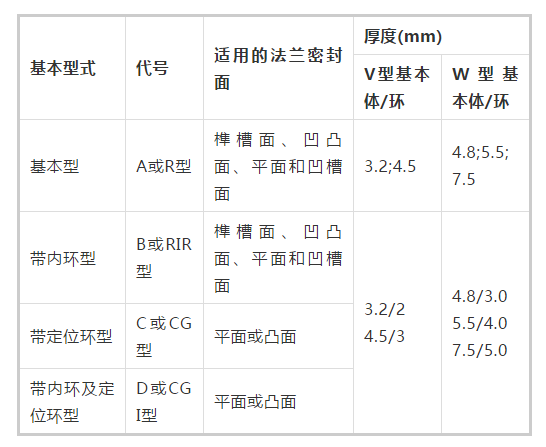

Basic Thickness Tolerance of Metal Wound Gaskets:

The following table shows the diameter tolerances of wound gaskets (i.e., the nominal pipe diameter for flanges):

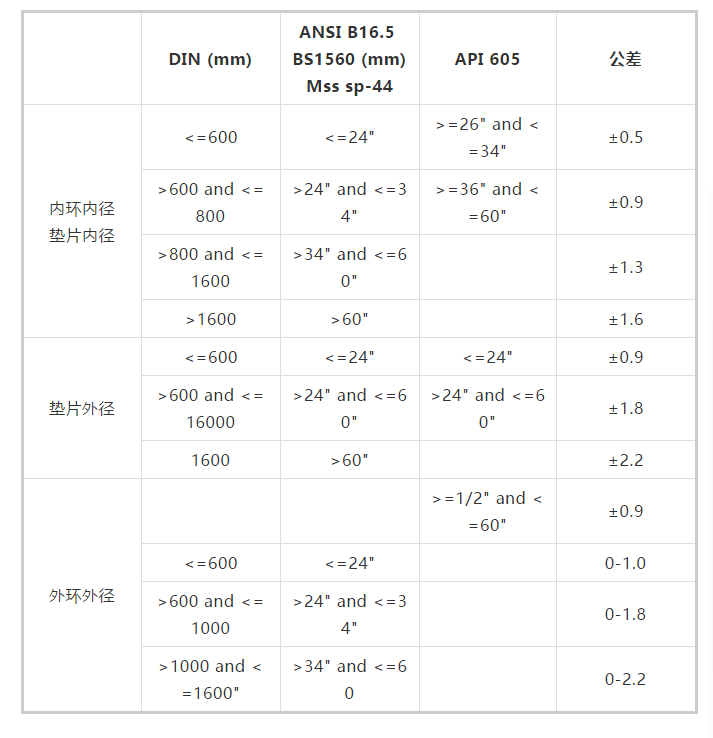

Main Performance Parameters of Metal Graphite Wound Gaskets:

Technical Standards:1. The international manufacturing standards for metal wound gaskets include: ASME B 16.20, ASME B 16.5, ASME B 16.47 A (B), BS EN1092, JIS, and NF, etc.2. Domestic standards includeHG/T20610-2009 Wound Gaskets for Steel Pipe Flanges Chemical Industry European System HG/T20631-2009 Wound Gaskets for Steel Pipe Flanges Chemical Industry American System GB/T4622.2-97 Wound Gaskets for Pipe Flanges National Standard JB/T4719-92 Wound Gaskets for Shell and Tube Heat Exchangers Mechanical Industry Standard JB/T90-2015 Wound Gaskets for Pipeline Flanges Mechanical Industry Standard JB/T4705-2000 Wound Gaskets for Pressure Vessel Flanges

DisclaimerThe source of this article is the internet for reference only. This platform maintains neutrality regarding reprints, sharing, statements, and viewpoints, with the sole purpose of conveying more information and does not represent the platform’s endorsement of its viewpoints or responsibility for its authenticity. If any political, factual, technical errors, or copyright issues are found, please contact us promptly for deletion. Thank you for your support!

For more updates, please follow us on WeChat, Douyin, Kuaishou, and other platforms:[ Asimi ] Editor WeChat ID: asimi888, and we welcome everyone to submit articles.

Asimi thanks you for your continued support, thank you!

If you need to purchase international standards and overseas books, please contact the editor.

Welcome to follow Asimi

Long press the QR code