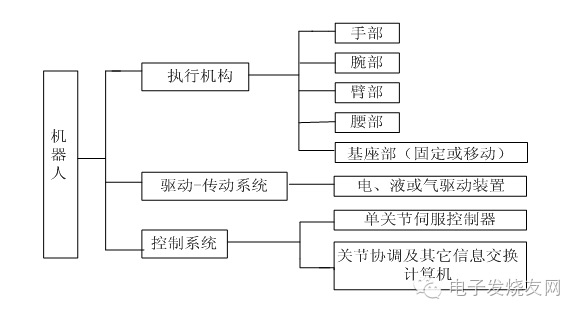

The history of robots is not very long. In 1959, American engineers George Devol and Joe Engelberger created the world’s first industrial robot, marking the true beginning of robotics. Engelberger studied servo theory in college, which is a theory that explores how motion mechanisms can better track control signals. Devol invented a system in 1946 that could “replay” the recorded movements of machines. In 1954, Devol obtained a patent for a programmable robotic arm, which could operate according to different programs tailored to various tasks, thus demonstrating versatility and flexibility. Both Engelberger and Devol believed that the automotive industry was most suitable for robots, as it involved heavy machinery and a relatively fixed production process. In 1959, Engelberger and Devol collaborated to manufacture the first industrial robot. 1. Milestones in Robot DevelopmentAccording to Techworld, the history of robots can be traced back to ancient Greece, where philosopher Aristotle discussed automated tools. The modern origins of robotics can be attributed to Henry Ford’s invention of the Model T assembly line.In Webster’s Dictionary, the definition of a robot is divided into three categories:First, a machine that resembles a human and can perform various complex human actions (such as walking and speaking), but often lacks human emotions.Second, a device capable of automatically executing complex tasks, adept at performing repetitive tasks.Third, a mechanism guided by automatic control. It is tempting to outline the history of robots in a linear fashion, from robotic arms manufacturing cars (definition 2) to humanoid robots exploring their surroundings (definition 3), ultimately leading to machines that can solve problems independently and defeat humans in games where humans excel (definition 1). However, the development of robots is not that simple.Recently, Techworld reviewed the milestone moments in the development of robots over the past 100 years, from industrial robotic arms to the birth of complex artificial intelligence. The concept of humanoid robots originates from science fiction, primarily from the works of American author Isaac Asimov.Asimov proposed the three laws of robotics in 1942:First Law: A robot may not injure a human being or, through inaction, allow a human being to come to harm.Second Law: A robot must obey the orders given it by human beings, except where such orders would conflict with the First Law.Third Law: A robot must protect its own existence as long as such protection does not conflict with the First or Second Law.1950: The Turing TestThe term Turing Test comes from a paper written by computer science and cryptography pioneer Alan Turing in 1950 titled “Computing Machinery and Intelligence.” Turing believed that if a machine could engage in conversation with a human without being distinguishable from a human, then that machine possessed intelligence. Although Turing’s method has been criticized for being overly simplistic, it has had a significant impact on human thought regarding artificial intelligence.1948: William Grey Walter Creates the Turtle RobotWalter is regarded as the first scientist to create an electronic robot, which he named machina speculatrix. Whenever its battery ran low, this turtle-like robot could find its way to a charging station. Walter’s creation laid the foundation for BEAM (Biology, Electronics, Aesthetics, and Mechanics) robots, which do not require microprocessors for computational power.1954: George Devol Applies for a Patent for a Programmable Robotic ArmDevol, along with Norman Heroux and Joe Engelberger, designed and manufactured the first programmable robotic arm, which they named Unimate, and sold it to General Motors in 1960. The birth of this industrial robot laid the groundwork for robots capable of performing repetitive, difficult, or dangerous tasks.1966: Stanford Research Institute Develops the Robot ShakeyBetween 1966 and 1972, the Stanford Research Institute designed the robot Shakey, a milestone event in the field of robotics as it combined hardware and software to perceive its environment. Shakey gained widespread media attention, bringing robots into public consciousness.1996: The Deep Blue Robot Defeats Chess Master Garry KasparovIn May 1997, IBM’s robot Deep Blue defeated world chess champion Kasparov in a formal match. In 1996, it had already defeated Kasparov in a private match.2000: Honda Launches the ASIMO RobotHonda introduced the classic humanoid robot ASIMO, designed as a personal assistant capable of understanding voice commands, gestures, and interacting with its environment.2004: IBM’s Watson SupercomputerWatson, the successor to Deep Blue, made headlines in 2008 when it defeated humans in the quiz show “Jeopardy!” This competition required the robot to possess complex natural language understanding capabilities. In 2011, Watson defeated human champions Ken Jennings and Brad Rutter.2016: Google’s AI System AlphaGo Defeats Go Champion Lee SedolIn a Go match held on March 15, 2016, Google’s subsidiary, British AI startup DeepMind, developed the AI system AlphaGo, which defeated world Go champion Lee Sedol. This was a significant milestone for the DeepMind development team, indicating that human-created AI can learn how to solve problems in any situation, whereas Deep Blue could only be pre-programmed for specific scenarios.2. Basic Components of RobotsCurrently, robots are typical mechatronic products, generally composed of four parts: the mechanical body, control system, sensors, and actuators. To achieve precise control of the body, sensors must provide information about the robot’s body or its environment. The control system generates command signals based on the control program, driving the actuators to move each joint according to the required trajectory, speed, and acceleration to reach a specified position in space. The actuators convert the signals output by the control system into high-power signals to drive the executors.1. Mechanical BodyThe mechanical body is the execution mechanism that allows the robot to complete its tasks, typically a robotic arm, also known as an end effector or manipulator, which can perform operations specified by the control system in a defined environment. The mechanical body of a typical industrial robot generally consists of a hand (end effector), wrist, arm, waist, and base. Robotic arms often use a jointed mechanical structure, typically having six degrees of freedom, with three used to determine the position of the end effector and the other three used to determine the orientation (posture) of the end effector. The end effector on the robotic arm can be replaced with various tools such as welding guns, suction cups, or wrenches according to operational needs.2. Control SystemThe control system is the command center of the robot, analogous to the brain’s function in humans, responsible for processing operational command information and internal and external environmental information, making decisions based on predetermined body models, environmental models, and control programs, generating corresponding control signals to drive the joints of the actuators in the required sequence along specified positions or trajectories to complete specific tasks. From the perspective of the control system’s composition, there are open-loop control systems and closed-loop control systems; from the control method, there are program control systems, adaptive control systems, and intelligent control systems.3. ActuatorsThe actuator is the power system of the robot, analogous to the cardiovascular system in humans, generally composed of a driving device and a transmission mechanism. Depending on the driving method, the driving device can be divided into electric, hydraulic, and pneumatic types. The motors, hydraulic cylinders, and pneumatic cylinders in the driving device can be directly connected to the manipulator or connected to the executors through the transmission mechanism. The transmission mechanism typically includes gear transmission, chain transmission, harmonic gear transmission, screw transmission, and belt transmission.4. SensorsSensors are the sensing system of the robot, analogous to the sensory organs in humans, and are an important component of the robot system, including internal sensors and external sensors. Internal sensors are mainly used to detect the robot’s own state, providing necessary body state information for the robot’s motion control, such as position sensors and speed sensors. External sensors are used to perceive the working environment or working condition information of the robot, which can be further divided into environmental sensors and end effector sensors. The former is used to identify objects and detect the distance between objects and the robot, while the latter is installed on the end effector to detect sensory information for delicate operations. Common external sensors include tactile sensors, proximity sensors, and visual sensors.

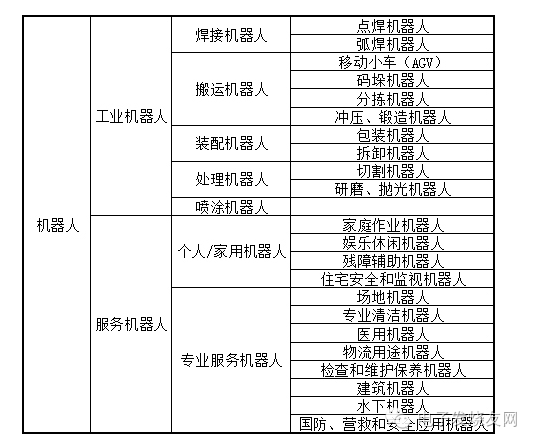

1. Milestones in Robot DevelopmentAccording to Techworld, the history of robots can be traced back to ancient Greece, where philosopher Aristotle discussed automated tools. The modern origins of robotics can be attributed to Henry Ford’s invention of the Model T assembly line.In Webster’s Dictionary, the definition of a robot is divided into three categories:First, a machine that resembles a human and can perform various complex human actions (such as walking and speaking), but often lacks human emotions.Second, a device capable of automatically executing complex tasks, adept at performing repetitive tasks.Third, a mechanism guided by automatic control. It is tempting to outline the history of robots in a linear fashion, from robotic arms manufacturing cars (definition 2) to humanoid robots exploring their surroundings (definition 3), ultimately leading to machines that can solve problems independently and defeat humans in games where humans excel (definition 1). However, the development of robots is not that simple.Recently, Techworld reviewed the milestone moments in the development of robots over the past 100 years, from industrial robotic arms to the birth of complex artificial intelligence. The concept of humanoid robots originates from science fiction, primarily from the works of American author Isaac Asimov.Asimov proposed the three laws of robotics in 1942:First Law: A robot may not injure a human being or, through inaction, allow a human being to come to harm.Second Law: A robot must obey the orders given it by human beings, except where such orders would conflict with the First Law.Third Law: A robot must protect its own existence as long as such protection does not conflict with the First or Second Law.1950: The Turing TestThe term Turing Test comes from a paper written by computer science and cryptography pioneer Alan Turing in 1950 titled “Computing Machinery and Intelligence.” Turing believed that if a machine could engage in conversation with a human without being distinguishable from a human, then that machine possessed intelligence. Although Turing’s method has been criticized for being overly simplistic, it has had a significant impact on human thought regarding artificial intelligence.1948: William Grey Walter Creates the Turtle RobotWalter is regarded as the first scientist to create an electronic robot, which he named machina speculatrix. Whenever its battery ran low, this turtle-like robot could find its way to a charging station. Walter’s creation laid the foundation for BEAM (Biology, Electronics, Aesthetics, and Mechanics) robots, which do not require microprocessors for computational power.1954: George Devol Applies for a Patent for a Programmable Robotic ArmDevol, along with Norman Heroux and Joe Engelberger, designed and manufactured the first programmable robotic arm, which they named Unimate, and sold it to General Motors in 1960. The birth of this industrial robot laid the groundwork for robots capable of performing repetitive, difficult, or dangerous tasks.1966: Stanford Research Institute Develops the Robot ShakeyBetween 1966 and 1972, the Stanford Research Institute designed the robot Shakey, a milestone event in the field of robotics as it combined hardware and software to perceive its environment. Shakey gained widespread media attention, bringing robots into public consciousness.1996: The Deep Blue Robot Defeats Chess Master Garry KasparovIn May 1997, IBM’s robot Deep Blue defeated world chess champion Kasparov in a formal match. In 1996, it had already defeated Kasparov in a private match.2000: Honda Launches the ASIMO RobotHonda introduced the classic humanoid robot ASIMO, designed as a personal assistant capable of understanding voice commands, gestures, and interacting with its environment.2004: IBM’s Watson SupercomputerWatson, the successor to Deep Blue, made headlines in 2008 when it defeated humans in the quiz show “Jeopardy!” This competition required the robot to possess complex natural language understanding capabilities. In 2011, Watson defeated human champions Ken Jennings and Brad Rutter.2016: Google’s AI System AlphaGo Defeats Go Champion Lee SedolIn a Go match held on March 15, 2016, Google’s subsidiary, British AI startup DeepMind, developed the AI system AlphaGo, which defeated world Go champion Lee Sedol. This was a significant milestone for the DeepMind development team, indicating that human-created AI can learn how to solve problems in any situation, whereas Deep Blue could only be pre-programmed for specific scenarios.2. Basic Components of RobotsCurrently, robots are typical mechatronic products, generally composed of four parts: the mechanical body, control system, sensors, and actuators. To achieve precise control of the body, sensors must provide information about the robot’s body or its environment. The control system generates command signals based on the control program, driving the actuators to move each joint according to the required trajectory, speed, and acceleration to reach a specified position in space. The actuators convert the signals output by the control system into high-power signals to drive the executors.1. Mechanical BodyThe mechanical body is the execution mechanism that allows the robot to complete its tasks, typically a robotic arm, also known as an end effector or manipulator, which can perform operations specified by the control system in a defined environment. The mechanical body of a typical industrial robot generally consists of a hand (end effector), wrist, arm, waist, and base. Robotic arms often use a jointed mechanical structure, typically having six degrees of freedom, with three used to determine the position of the end effector and the other three used to determine the orientation (posture) of the end effector. The end effector on the robotic arm can be replaced with various tools such as welding guns, suction cups, or wrenches according to operational needs.2. Control SystemThe control system is the command center of the robot, analogous to the brain’s function in humans, responsible for processing operational command information and internal and external environmental information, making decisions based on predetermined body models, environmental models, and control programs, generating corresponding control signals to drive the joints of the actuators in the required sequence along specified positions or trajectories to complete specific tasks. From the perspective of the control system’s composition, there are open-loop control systems and closed-loop control systems; from the control method, there are program control systems, adaptive control systems, and intelligent control systems.3. ActuatorsThe actuator is the power system of the robot, analogous to the cardiovascular system in humans, generally composed of a driving device and a transmission mechanism. Depending on the driving method, the driving device can be divided into electric, hydraulic, and pneumatic types. The motors, hydraulic cylinders, and pneumatic cylinders in the driving device can be directly connected to the manipulator or connected to the executors through the transmission mechanism. The transmission mechanism typically includes gear transmission, chain transmission, harmonic gear transmission, screw transmission, and belt transmission.4. SensorsSensors are the sensing system of the robot, analogous to the sensory organs in humans, and are an important component of the robot system, including internal sensors and external sensors. Internal sensors are mainly used to detect the robot’s own state, providing necessary body state information for the robot’s motion control, such as position sensors and speed sensors. External sensors are used to perceive the working environment or working condition information of the robot, which can be further divided into environmental sensors and end effector sensors. The former is used to identify objects and detect the distance between objects and the robot, while the latter is installed on the end effector to detect sensory information for delicate operations. Common external sensors include tactile sensors, proximity sensors, and visual sensors. 3. Classification of RobotsChinese robotics experts classify robots into two main categories based on their application environment: industrial robots and special robots. Industrial robots refer to multi-joint mechanical arms or multi-degree-of-freedom robots aimed at the industrial sector. Special robots, on the other hand, are various advanced robots used in non-manufacturing sectors to serve humans, including service robots, underwater robots, entertainment robots, military robots, agricultural robots, and robotic machines.Among special robots, some branches are developing rapidly and tend to form independent systems, such as service robots, underwater robots, military robots, and micro-operation robots.The International Federation of Robotics classifies robots into two categories: industrial robots and service robots. Industrial robots are defined as “a type of robot used in industrial automation, containing three or more programmable axes, automatically controlled, programmable, and multifunctional executors, which can be either fixed or mobile.” Service robots are defined as “a robot that works semi-autonomously or fully autonomously, capable of performing beneficial service work for human health, but not including production equipment.” This classification is generally consistent with that of China.

3. Classification of RobotsChinese robotics experts classify robots into two main categories based on their application environment: industrial robots and special robots. Industrial robots refer to multi-joint mechanical arms or multi-degree-of-freedom robots aimed at the industrial sector. Special robots, on the other hand, are various advanced robots used in non-manufacturing sectors to serve humans, including service robots, underwater robots, entertainment robots, military robots, agricultural robots, and robotic machines.Among special robots, some branches are developing rapidly and tend to form independent systems, such as service robots, underwater robots, military robots, and micro-operation robots.The International Federation of Robotics classifies robots into two categories: industrial robots and service robots. Industrial robots are defined as “a type of robot used in industrial automation, containing three or more programmable axes, automatically controlled, programmable, and multifunctional executors, which can be either fixed or mobile.” Service robots are defined as “a robot that works semi-autonomously or fully autonomously, capable of performing beneficial service work for human health, but not including production equipment.” This classification is generally consistent with that of China. There are also classifications based on load weight, control methods, degrees of freedom, structure, and application fields.Common classification methods:Teaching Reproduction Robots:These robots learn actions through guidance or other means, input work programs, and then automatically repeat tasks.CNC Robots:These robots do not require physical movement; they are taught through numerical or language inputs and perform tasks based on the taught information.Sensing Control Robots:These robots control their actions using information obtained from sensors.Adaptive Control Robots:These robots can adapt to changes in the environment and control their own actions.Learning Control Robots:These robots can “experience” work and possess a certain learning function, applying the learned experience to their tasks.Intelligent Robots:These robots determine their actions based on artificial intelligence.4. Advantages and Disadvantages of RobotsAdvantages of Using RobotsRobots and automation technology can often improve productivity, safety, efficiency, product quality, and uniformity;Robots can work in hazardous environments without concerns for life support or safety needs;Robots do not require comfortable environments, such as considerations for lighting, air conditioning, ventilation, or noise isolation;Robots can work tirelessly and without boredom; they do not experience psychological issues, do not procrastinate, and do not require medical insurance or vacations;Robots maintain precision consistently, except for failures or wear;Robots have a much higher precision than humans. Linear displacement accuracy can reach thousandths of an inch (1 inch = 2.54 cm), and new semiconductor chip processing robots have micro-inch level precision;Robots and their associated devices and sensors possess certain capabilities that humans do not;Robots can respond to multiple stimuli or handle multiple tasks simultaneously, while humans can only respond to one current stimulus.Disadvantages of Using RobotsRobots replace workers, leading to economic and social issues;Robots lack emergency capabilities; unless the emergency situation can be anticipated and a response plan has been set in the system, they cannot handle emergencies well. Additionally, safety measures are needed to ensure that robots do not harm operators or the machines (equipment) they work with. These situations include inappropriate or incorrect responses, lack of decision-making ability, power outages, damage to robots or other equipment, and personnel injuries;Although robots excel in certain situations, their capabilities still have limitations compared to humans, manifested in degrees of freedom, dexterity, sensor capabilities, visual systems, and real-time responses.5. Performance Indicators of RobotsThe following are used to define the performance indicators of robots:Load Capacity:Load capacity is the weight a robot can bear while meeting other performance requirements. For example, a robot’s maximum load capacity may be much greater than its rated load capacity, but when reaching maximum load, the robot’s working accuracy may decrease, and it may not be able to move accurately along the predetermined trajectory or may produce additional deviations. The load capacity of robots is often very small compared to their own weight. For example, the Fanuc Robotics LR Mate robot weighs 86 pounds, while its load capacity is only 6.6 pounds; the M16 robot weighs 594 pounds, while its load capacity is only 35 pounds.Range of Motion:The range of motion is the maximum distance a robot can reach within its working area. Robots can reach many points within their working area in any posture (these points are called dexterous points). However, for some points close to the limits of the robot’s range of motion, their posture cannot be arbitrarily specified (these points are called non-dexterous points). Note: The range of motion is a function of the robot’s joint lengths and configuration.Accuracy:Accuracy refers to the degree of precision with which a robot reaches a specified point. Note: It is related to the resolution of the actuators and the feedback devices. Most industrial robots have an accuracy of 0.001 inches or higher.Repeatability:Repeatability refers to the degree of precision with which a robot can reach the same position if the action is repeated multiple times. For example, if a robot is driven to the same point 100 times, due to various factors affecting the robot’s positional accuracy, it cannot reach the exact same point every time, but should fall within a circular area centered on that point. The radius of this circle is formed by a series of repeated actions, and this radius is the repeatability. Note: Repeatability is more important than accuracy; if a robot’s positioning is not precise enough, it usually shows a fixed error that can be predicted and thus corrected through programming. For example, if a robot consistently deviates to the right by 0.01mm, all position points can be specified to shift left by 0.01mm, thus eliminating the deviation. Note: If the error is random, it cannot be predicted and therefore cannot be eliminated. The repeatability limits the range of such random errors, usually determined by running the robot a certain number of times.

There are also classifications based on load weight, control methods, degrees of freedom, structure, and application fields.Common classification methods:Teaching Reproduction Robots:These robots learn actions through guidance or other means, input work programs, and then automatically repeat tasks.CNC Robots:These robots do not require physical movement; they are taught through numerical or language inputs and perform tasks based on the taught information.Sensing Control Robots:These robots control their actions using information obtained from sensors.Adaptive Control Robots:These robots can adapt to changes in the environment and control their own actions.Learning Control Robots:These robots can “experience” work and possess a certain learning function, applying the learned experience to their tasks.Intelligent Robots:These robots determine their actions based on artificial intelligence.4. Advantages and Disadvantages of RobotsAdvantages of Using RobotsRobots and automation technology can often improve productivity, safety, efficiency, product quality, and uniformity;Robots can work in hazardous environments without concerns for life support or safety needs;Robots do not require comfortable environments, such as considerations for lighting, air conditioning, ventilation, or noise isolation;Robots can work tirelessly and without boredom; they do not experience psychological issues, do not procrastinate, and do not require medical insurance or vacations;Robots maintain precision consistently, except for failures or wear;Robots have a much higher precision than humans. Linear displacement accuracy can reach thousandths of an inch (1 inch = 2.54 cm), and new semiconductor chip processing robots have micro-inch level precision;Robots and their associated devices and sensors possess certain capabilities that humans do not;Robots can respond to multiple stimuli or handle multiple tasks simultaneously, while humans can only respond to one current stimulus.Disadvantages of Using RobotsRobots replace workers, leading to economic and social issues;Robots lack emergency capabilities; unless the emergency situation can be anticipated and a response plan has been set in the system, they cannot handle emergencies well. Additionally, safety measures are needed to ensure that robots do not harm operators or the machines (equipment) they work with. These situations include inappropriate or incorrect responses, lack of decision-making ability, power outages, damage to robots or other equipment, and personnel injuries;Although robots excel in certain situations, their capabilities still have limitations compared to humans, manifested in degrees of freedom, dexterity, sensor capabilities, visual systems, and real-time responses.5. Performance Indicators of RobotsThe following are used to define the performance indicators of robots:Load Capacity:Load capacity is the weight a robot can bear while meeting other performance requirements. For example, a robot’s maximum load capacity may be much greater than its rated load capacity, but when reaching maximum load, the robot’s working accuracy may decrease, and it may not be able to move accurately along the predetermined trajectory or may produce additional deviations. The load capacity of robots is often very small compared to their own weight. For example, the Fanuc Robotics LR Mate robot weighs 86 pounds, while its load capacity is only 6.6 pounds; the M16 robot weighs 594 pounds, while its load capacity is only 35 pounds.Range of Motion:The range of motion is the maximum distance a robot can reach within its working area. Robots can reach many points within their working area in any posture (these points are called dexterous points). However, for some points close to the limits of the robot’s range of motion, their posture cannot be arbitrarily specified (these points are called non-dexterous points). Note: The range of motion is a function of the robot’s joint lengths and configuration.Accuracy:Accuracy refers to the degree of precision with which a robot reaches a specified point. Note: It is related to the resolution of the actuators and the feedback devices. Most industrial robots have an accuracy of 0.001 inches or higher.Repeatability:Repeatability refers to the degree of precision with which a robot can reach the same position if the action is repeated multiple times. For example, if a robot is driven to the same point 100 times, due to various factors affecting the robot’s positional accuracy, it cannot reach the exact same point every time, but should fall within a circular area centered on that point. The radius of this circle is formed by a series of repeated actions, and this radius is the repeatability. Note: Repeatability is more important than accuracy; if a robot’s positioning is not precise enough, it usually shows a fixed error that can be predicted and thus corrected through programming. For example, if a robot consistently deviates to the right by 0.01mm, all position points can be specified to shift left by 0.01mm, thus eliminating the deviation. Note: If the error is random, it cannot be predicted and therefore cannot be eliminated. The repeatability limits the range of such random errors, usually determined by running the robot a certain number of times.