1. Background and Application Value of MBD Technology

In the field of automotive electronics, Model-Based Design (MBD) has become the mainstream method for embedded system development. Compared to traditional handwritten code development, MBD achieves algorithm visualization design through graphical modeling (such as Simulink/Stateflow). Its core advantages include:

– Early design verification: Algorithm logic can be verified during the simulation phase, reducing the risk of real vehicle debugging.

– Automatic code generation: Tools like Embedded Coder generate ISO 26262 compliant code.

– Multi-domain collaboration: Supports co-simulation of control algorithms and physical modeling (such as Simscape).

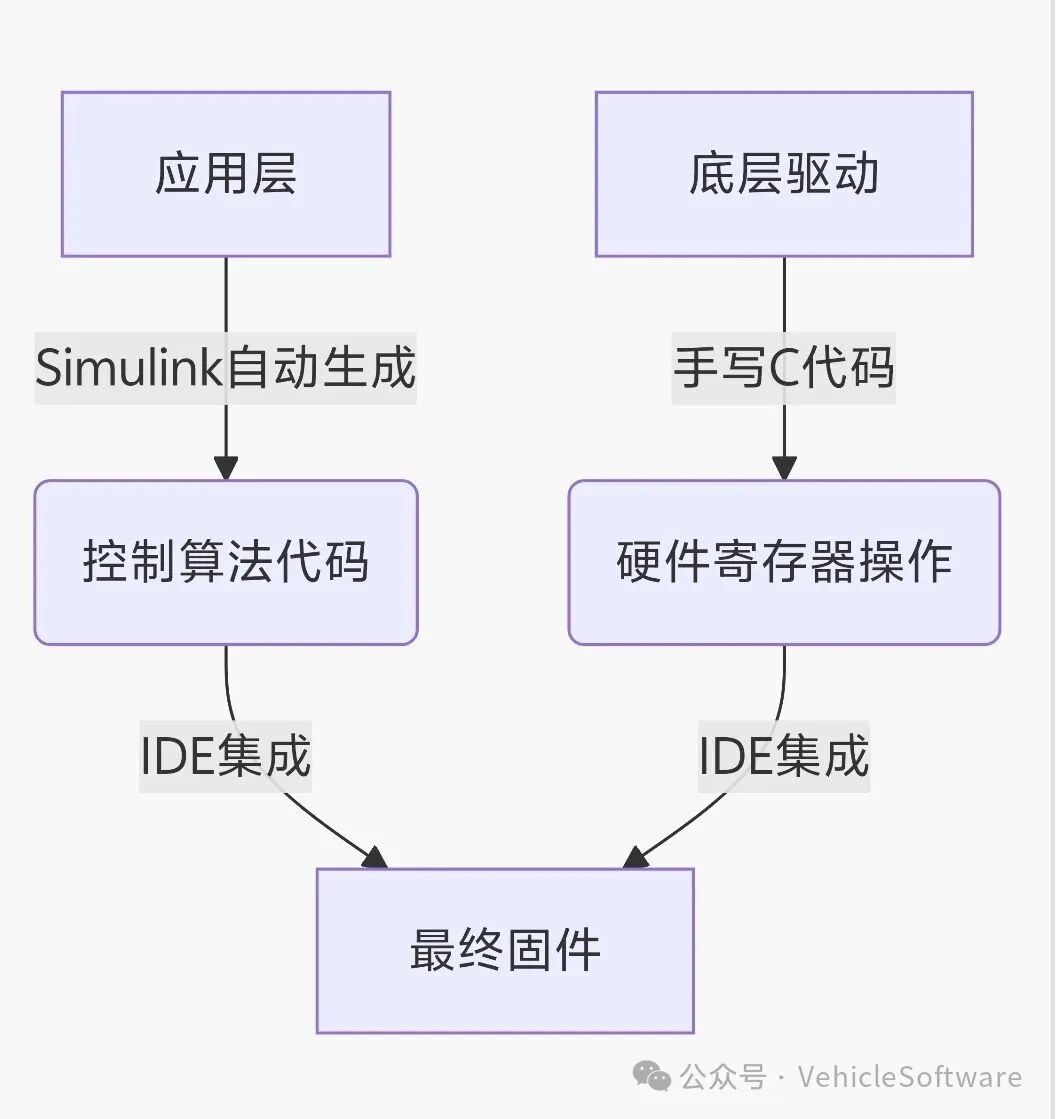

Currently, a layered architecture has become the industry standard in automotive electronic development:

2. Detailed Explanation of Simulink Model Construction

1. Requirement Analysis and Model Architecture

This example implements the core logic for blinking an LED connected to P1.0 at a frequency of 1Hz:

Period T=1s:

First 0.5s → P1.0=1 (LED on)

Last 0.5s → P1.0=0 (LED off)

The corresponding Simulink model needs to include two key modules:

– Pulse Generator: Generates a square wave with a 50% duty cycle.

– Data Type Conversion: Converts boolean values to uint8 for hardware interface.

2. Hardware Interface Mapping

Associate hardware resources through the GPIO Write module:

// Low-level register mapping (implemented in Keil project)

sfr P1 = 0x90; // SFR address of P1 port for 8051

Common mistake avoidance: Ensure to set the port number (Port) of the GPIO Write module to 1 (corresponding to P1), and the pin number (Pin) to 0 (i.e., P1.0).

3. In-depth Configuration of Automatic Code Generation

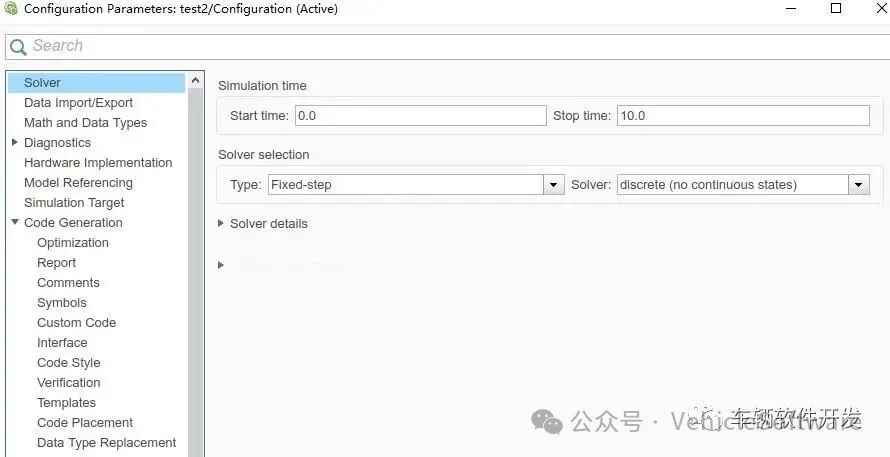

1. Key Considerations for Solver Selection

Embedded systems should choose a fixed-step solver:

– Real-time assurance: Avoid timing jitter caused by variable step sizes.

– Resource optimization: Fixed execution cycles reduce CPU usage.

2. Target System Configuration

Three main reasons for selecting the ert.tlc target file:

1. Generates code that complies with MISRA-C standards.

2. Supports code efficiency optimization (e.g., inline functions).

3. Provides comprehensive code comments for traceability.

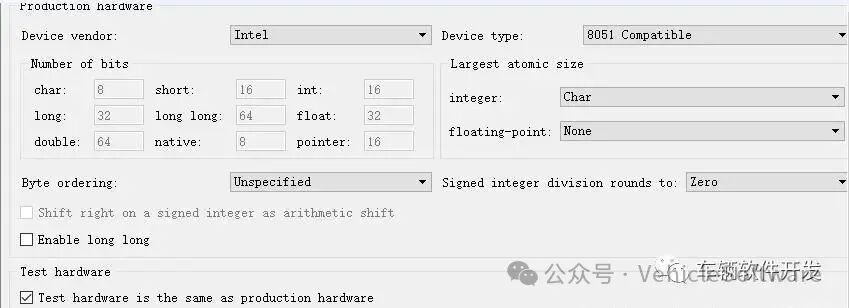

3. Hardware Device Specification

The 8051 Device option directly affects the generated port operation code:

// Example of automatically generated code

void LED_step(void) {

P1 &= 0xFE; // Clear P1.0 bit (generated by Embedded Coder based on hardware configuration)

}

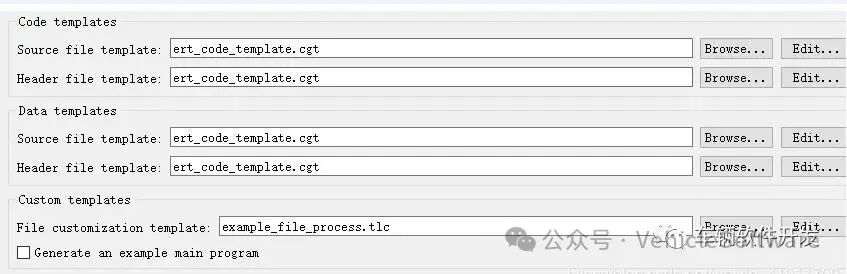

4. Customization of Interface Settings

Uncheck the option to generate the main function example to fit the existing project framework:

– Avoid conflicts with the startup files in the Keil project.

– Retain custom initialization processes.

4. Key Technologies for Keil Project Integration

1. File Organization Structure

Project/

├── App/

│ ├── LED_generated.c // Simulink auto-generated code

│ └── LED.h

├── Driver/

│ ├── GPIO.c // Handwritten low-level driver

│ └── Timer.c

└── main.c // Main scheduling program

2. Example of Handwritten Low-Level Driver

// GPIO.c

void GPIO_Init() {

P1 = 0x00; // Initialize P1 port to low level

P1M0 = 0x01; // Set P1.0 as push-pull output (specific configuration for STC89C52)

}

// main.c

extern void LED_initialize(void);

extern void LED_step(void);

void main() {

GPIO_Init();

LED_initialize(); // Model initialization function

while(1) {

LED_step(); // Model step function

Timer_Delay(1); // 1ms delay

}

}

Reusable design: If the same hardware interface is maintained, subsequent model modifications only require replacing the

“LED_generated.*” files and recompiling.

5. Full Process Verification with Proteus Simulation

1. Circuit Design Specifications

– Microcontroller Model: AT89C52 (compatible with 8051 instruction set)

– LED Connection: P1.0 → 220Ω current limiting resistor → LED anode → GND

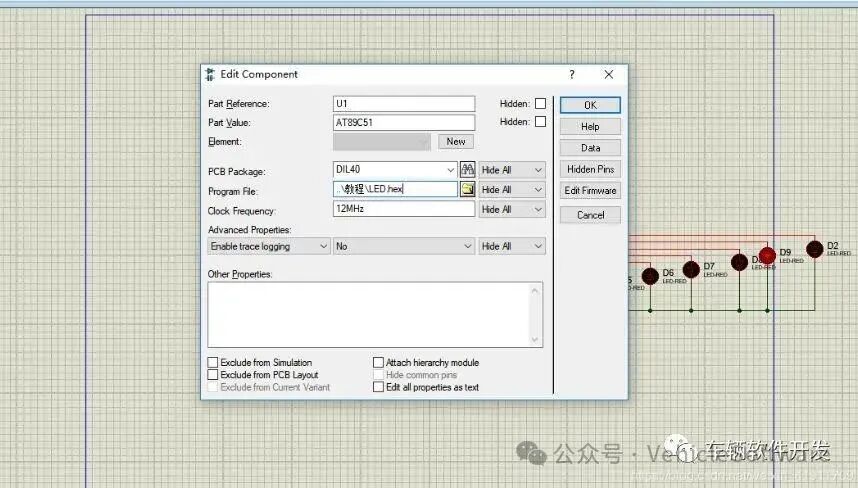

2. HEX File Loading Steps

Double-click the microcontroller chip in Proteus:

– Select the path of the HEX file generated by Keil.

– Set the clock frequency (default 11.0592MHz).

3. Simulation Verification Indicators

– Timing accuracy: Use an oscilloscope to detect that the P1.0 waveform period should be 1s ±5%.

– Power consumption performance: The current meter detects the LED circuit current to be about 3mA (compliant with safety standards).

Debugging tip: If the LED does not blink, check if the “Digital Animation” in Proteus is enabled.

6. Engineering Experience Expansion

1. Special Requirements for Automotive Electronic Development

– Timing constraints: Adjust task scheduling order through Simulink’s Execution Order.

– Code safety: Enable CRC check function in Embedded Coder (ISO 26262 requirement).

2. Mass Production Optimization Solutions

// Encapsulate low-level drivers as Simulink S-Function (advanced usage)

static void mdlOutputs(SimStruct *S, int_T tid) {

uint8_T *y = ssGetOutputPortSignal(S,0);

P1 = (P1 & 0xFE) | (*y & 0x01); // Only modify P1.0

}

3. Common Problem Troubleshooting Table

Phenomenon Possible Cause Solution

Code compilation error Model header file not included Add inc path in Keil

LED always on/off GPIO initialization configuration error Check P1M0 register configuration

Flashing frequency deviation >10% Timer interrupt not enabled Confirm Timer_Delay.