Video Recommendations

In the field of industrial control, the core board is the “heart” of the system, and its selection is crucial. Today, we will discuss how to choose a suitable and reliable industrial control core board to make your product stand out in terms of performance and stability.

1. Processor

The processor is key to the core board, including the processor architecture and performance. There are various architectures available on the market, such as ARM, MIPS, and RISC-V. Regardless of the architecture, the performance must meet the product planning requirements; otherwise, it should be excluded. Different processor architectures have their advantages in power consumption, performance, and compatibility, which need to be weighed according to specific application scenarios.

2. Operating System

The choice of operating system has a profound impact on software development, involving software ecosystem, boot speed, system security, power consumption control, and real-time response. Different operating systems perform differently in these aspects; for example, Linux is widely popular for its open-source nature and strong community support, but it is relatively weak in real-time performance; while some real-time operating systems (RTOS) excel in real-time response but may lack in software ecosystem.

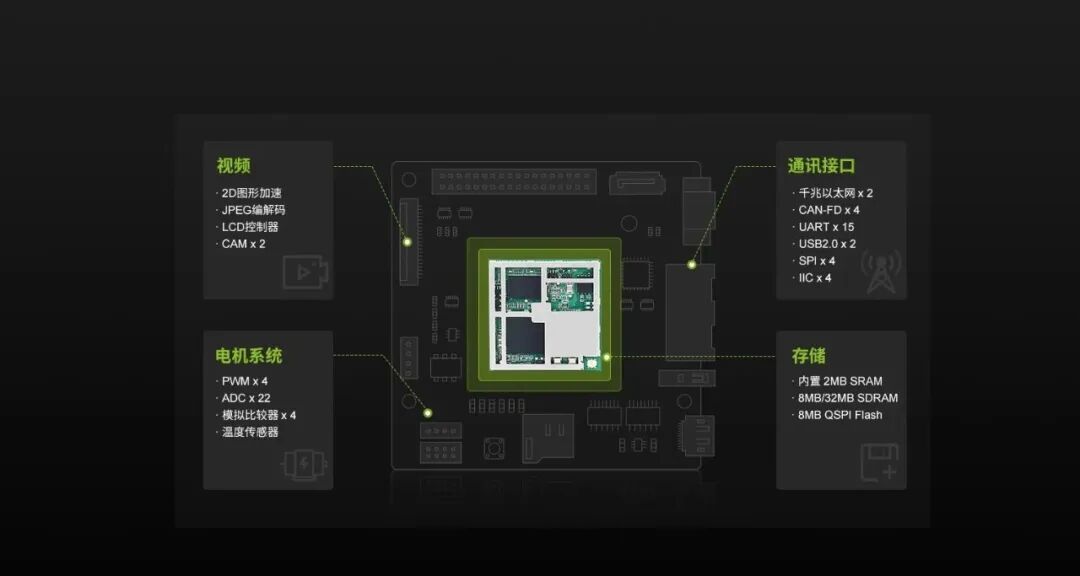

3. Peripheral Interfaces

The compatibility of peripheral interfaces is very important, including the number of interfaces, interface performance, and the ability to expand, as well as the cost of expansion. One point to note is that the number of interfaces listed in the core board parameters is the maximum number, but chips often have pin multiplexing, and there may be functional conflicts between interfaces, which must be confirmed.

4. Product Price

When selecting a core board, one should not only look at the price of the core board itself but also consider the overall product cost, including BOM costs and other hidden costs such as software development, technical support, and after-sales service.

5. Product Stability

Industrial products have extremely high stability requirements. The core board must undergo rigorous stability testing, such as high and low temperature tests and anti-interference tests, and provide relevant reports; this is very important.

6. Product Compliance

Product compliance should not be overlooked, such as RoHS and REACH certifications. These certifications are basic requirements for products entering the market, especially in industries with high environmental and safety requirements, compliance certification is essential.

7. Supplier Reputation

The reputation of the supplier is crucial, including their scale, technical research and development capabilities, production processing capabilities, quality control capabilities, technical service capabilities, and supply capabilities. Choosing a reliable manufacturer means you will gain not just a supplier but a partner who can provide comprehensive assistance in product development.

END

Source:ZLG Zhiyuan Electronics

Copyright belongs to the original author. If there is any infringement, please contact for deletion..▍Recommended ReadingSharing several BootLoaders suitable for MCUWhy some domestic chips do not disclose data sheets?Incredible! These 17 C pointer tricks have made countless programmers collect them overnight→ Follow for more updates ←