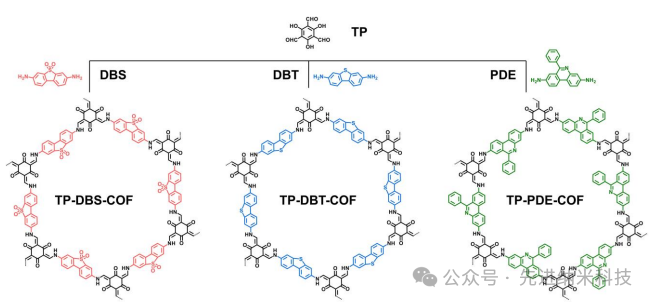

Research BackgroundHydrogen peroxide (H₂O₂), as a green oxidant, has wide applications in bleaching, disinfection, environmental remediation, and green energy storage. However, traditional methods for producing hydrogen peroxide (such as the anthraquinone process) are energy-intensive and generate a large amount of harmful waste. Therefore, developing sustainable photocatalytic methods for H₂O₂ production has become a research hotspot. Covalent organic frameworks (COFs) have emerged as promising photocatalysts due to their high porosity and tunable structures, but their hydrophobicity limits mass transfer efficiency in water, affecting photocatalytic performance. Combining COFs with hydrophilic zeolites is expected to enhance H₂O₂ production efficiency, but effectively integrating these two types of porous materials poses a challenge.The team led by Ji Hong and Jin Enquan from Jilin University has successfully utilized 3D printing technology to prepare COF/zeolite composite photocatalysts. By precisely optimizing the binder and prepolymerization conditions, they developed a uniform ink with appropriate rheological properties, enabling the in-situ growth and crystallization of COFs within the 3D printed structure. The study found that the introduction of zeolites significantly improved the hydrophilicity and oxygen adsorption capacity of the composite material, thereby promoting the photocatalytic generation of H₂O₂. Experimental results indicated that the H₂O₂ production efficiency of the COF/zeolite composite material increased by 52% compared to pure COFs. This work was published under the title “3D-Printed COF/Zeolite Composites for Augmented Photocatalytic Hydrogen Peroxide Production” in the journal Angewandte Chemie International Edition.

Research BackgroundHydrogen peroxide (H₂O₂), as a green oxidant, has wide applications in bleaching, disinfection, environmental remediation, and green energy storage. However, traditional methods for producing hydrogen peroxide (such as the anthraquinone process) are energy-intensive and generate a large amount of harmful waste. Therefore, developing sustainable photocatalytic methods for H₂O₂ production has become a research hotspot. Covalent organic frameworks (COFs) have emerged as promising photocatalysts due to their high porosity and tunable structures, but their hydrophobicity limits mass transfer efficiency in water, affecting photocatalytic performance. Combining COFs with hydrophilic zeolites is expected to enhance H₂O₂ production efficiency, but effectively integrating these two types of porous materials poses a challenge.The team led by Ji Hong and Jin Enquan from Jilin University has successfully utilized 3D printing technology to prepare COF/zeolite composite photocatalysts. By precisely optimizing the binder and prepolymerization conditions, they developed a uniform ink with appropriate rheological properties, enabling the in-situ growth and crystallization of COFs within the 3D printed structure. The study found that the introduction of zeolites significantly improved the hydrophilicity and oxygen adsorption capacity of the composite material, thereby promoting the photocatalytic generation of H₂O₂. Experimental results indicated that the H₂O₂ production efficiency of the COF/zeolite composite material increased by 52% compared to pure COFs. This work was published under the title “3D-Printed COF/Zeolite Composites for Augmented Photocatalytic Hydrogen Peroxide Production” in the journal Angewandte Chemie International Edition.

Article Highlights

-

Innovative 3D Printing Technology: This is the first application of 3D printing technology in the preparation of COF/zeolite composites, achieving precise structural design and efficient mass transfer channels.

-

Significantly Enhanced Photocatalytic Performance: By optimizing the zeolite content, a significant increase in H₂O₂ production efficiency was achieved, reaching up to 52%.

-

Enhanced Hydrophilicity and Oxygen Affinity: The introduction of zeolites significantly improved the hydrophilicity and oxygen adsorption capacity of the composite material, facilitating the photocatalytic reaction pathway.

Scientific Problems Addressed

-

Hydrophobicity Limitation: The introduction of hydrophilic zeolites addressed the low mass transfer efficiency of COFs in water.

-

Material Integration Challenge: Using 3D printing technology, the successful integration of COFs and zeolites was achieved, avoiding phase separation issues common in traditional methods.

-

Balance of Crystallinity and Porosity: 3D printing technology enabled high crystallinity and porosity of COFs, enhancing photocatalytic performance.

Application Prospects

-

Environmental Remediation: The efficient H₂O₂ generation capability offers broad application prospects in water treatment and environmental remediation.

-

Green Chemical Synthesis: Provides a green and efficient alternative for sustainable H₂O₂ production.

-

Materials Science: The application of 3D printing technology offers new ideas for the preparation of other functional materials, potentially advancing the field of materials science.

Original Article Information:

J. Feng, Y. Wei, X. Li, et. al., 3D-Printed COF/Zeolite Composites for Augmented Photocatalytic Hydrogen Peroxide Production, Angew. Chem. Int. Ed., 2025, e202508226.

Original Link:https://doi.org/10.1002/anie.202508226

The above content represents the personal views of the author and is for reference only. Please feel free to provide criticism and corrections if there are any inaccuracies!