In today’s composite materials field, carbon fiber and glass fiber dominate high-end sectors such as aerospace and automotive industries due to their excellent mechanical properties.However, the production of these synthetic fibers often requires temperatures exceeding 1000K and lengthy processing times, resulting in enormous energy consumption and high costs. When we talk about breakthroughs in composite 3D printing materials, few would think of bamboo.Can the performance of bamboo fiber composites compare with other composites?The latest research results published by the team from Soochow University in the international materials journal “Materials” breathe new life into this ancient plant.

When we talk about breakthroughs in composite 3D printing materials, few would think of bamboo.Can the performance of bamboo fiber composites compare with other composites?The latest research results published by the team from Soochow University in the international materials journal “Materials” breathe new life into this ancient plant. This research innovatively combines bamboo fiber with 3D printing technology, achieving a leap in performance and providing a new approach for the green transformation of additive manufacturing.A revolution in material thinkingWhy bamboo? Can bamboo work?This may be the first reaction of many people.In fact, against the backdrop of the global push for dual carbon goals, this choice reflects a vision for sustainability.While traditional carbon fibers have excellent performance, their production requires high temperatures and lengthy processes, leading to significant energy consumption and environmental burdens.In contrast, the remarkable aspect of bamboo fiber is that it can achieve a tensile strength of 1.9GPa comparable to carbon fiber, but importantly, its production only consumes 8% of the cost and 3% of the energy required for carbon fiber.However, applying bamboo fiber in 3D printing is not an easy task.

This research innovatively combines bamboo fiber with 3D printing technology, achieving a leap in performance and providing a new approach for the green transformation of additive manufacturing.A revolution in material thinkingWhy bamboo? Can bamboo work?This may be the first reaction of many people.In fact, against the backdrop of the global push for dual carbon goals, this choice reflects a vision for sustainability.While traditional carbon fibers have excellent performance, their production requires high temperatures and lengthy processes, leading to significant energy consumption and environmental burdens.In contrast, the remarkable aspect of bamboo fiber is that it can achieve a tensile strength of 1.9GPa comparable to carbon fiber, but importantly, its production only consumes 8% of the cost and 3% of the energy required for carbon fiber.However, applying bamboo fiber in 3D printing is not an easy task. Traditional mixing-injection molding processes can lead to severe fiber breakage, with 5mm natural fibers often shortening to 0.28mm during processing, losing the advantage of continuous reinforcement.Although resin transfer molding (RTM) technology can maintain fiber continuity, the high viscosity characteristics of thermoplastic resins (nearly three orders of magnitude higher than epoxy resins) make this technical route difficult to sustain.Illuminating insight: From bamboo to high-performance compositesFaced with this technical challenge, the research team from Soochow University innovatively proposed a two-step process of “alkali treatment + 3D printing”.

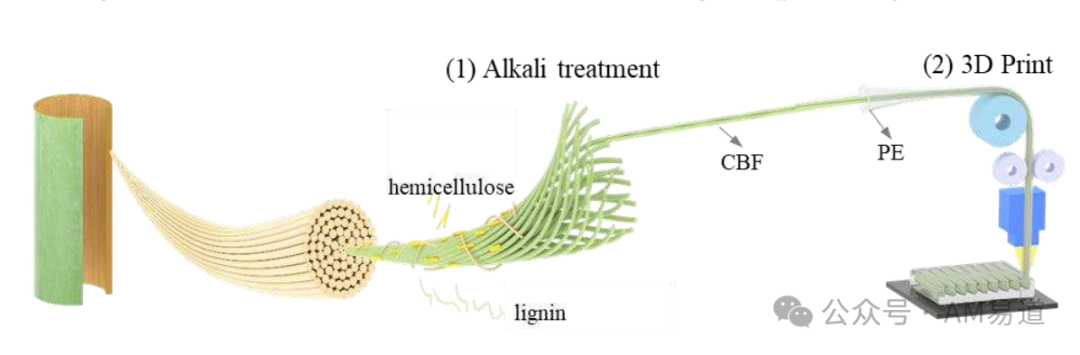

Traditional mixing-injection molding processes can lead to severe fiber breakage, with 5mm natural fibers often shortening to 0.28mm during processing, losing the advantage of continuous reinforcement.Although resin transfer molding (RTM) technology can maintain fiber continuity, the high viscosity characteristics of thermoplastic resins (nearly three orders of magnitude higher than epoxy resins) make this technical route difficult to sustain.Illuminating insight: From bamboo to high-performance compositesFaced with this technical challenge, the research team from Soochow University innovatively proposed a two-step process of “alkali treatment + 3D printing”. This seemingly simple combination actually solves a series of technical challenges in the preparation of continuous fiber-reinforced composites.The first step is alkali treatment.The team selected high-quality bamboo fibers with an initial length of 9cm and a diameter between 0.12-0.30mm.These fibers were immersed in a specially formulated mixed solution (2.5M NaOH and 0.4M Na2SO3, pH 14.4) and subjected to precise treatment at 80℃ for 24 hours.In a constant temperature environment of 80℃, after 24 hours, the microstructure of the bamboo fibers underwent remarkable changes:The surface roughness increased from 6.98μm to 11.01μm, and the diameter was optimized from 240μm to 200μm.

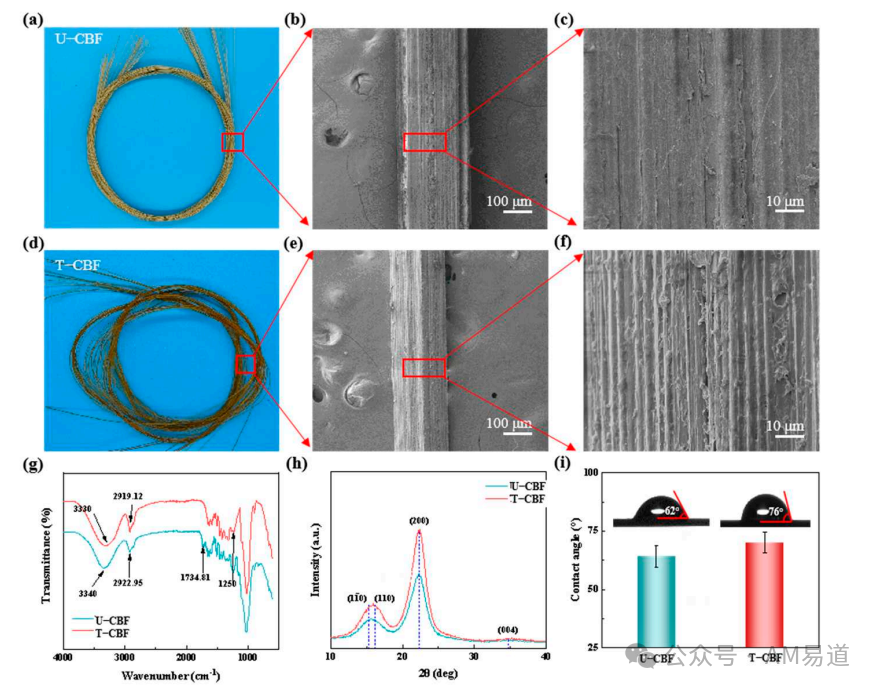

This seemingly simple combination actually solves a series of technical challenges in the preparation of continuous fiber-reinforced composites.The first step is alkali treatment.The team selected high-quality bamboo fibers with an initial length of 9cm and a diameter between 0.12-0.30mm.These fibers were immersed in a specially formulated mixed solution (2.5M NaOH and 0.4M Na2SO3, pH 14.4) and subjected to precise treatment at 80℃ for 24 hours.In a constant temperature environment of 80℃, after 24 hours, the microstructure of the bamboo fibers underwent remarkable changes:The surface roughness increased from 6.98μm to 11.01μm, and the diameter was optimized from 240μm to 200μm. Through scanning electron microscopy observation (Figure 2), we can clearly see the significant changes before and after treatment: untreated bamboo fibers (U-CBF) appear light yellow and have a relatively smooth surface;while treated bamboo fibers (T-CBF) appear dark yellow with significantly increased surface roughness.This change not only enhances the mechanical properties of the fibers but also creates ideal conditions for subsequent bonding with the PE matrix.More in-depth characterization results (Figures 2g-i) reveal the microstructural changes of the material:FT-IR spectra show a significant reduction in the peaks at 1734cm⁻¹ (hemicellulose characteristic peak) and 1250cm⁻¹ (lignin characteristic peak)XRD analysis indicates an increase in the intensity of crystalline peaks and a decrease in half-peak width, indicating improved crystallinity of celluloseContact angle tests show that T-CBF’s hydrophobicity is enhanced, which is beneficial for interfacial bonding with the PE matrixSubsequently, the fibers were washed three times with distilled water and finally dried at 75℃ for 12 hours.Mechanical performance tests (Figure 3) demonstrate the effects of treatment:Tensile strength increased from 553.7±59.7MPa to 672.3±49.6MPa, an increase of 21%Toughness increased from 666.3J/m³ to 1067.2J/m³, nearly a 60% increaseYoung’s modulus increased by 30%

Through scanning electron microscopy observation (Figure 2), we can clearly see the significant changes before and after treatment: untreated bamboo fibers (U-CBF) appear light yellow and have a relatively smooth surface;while treated bamboo fibers (T-CBF) appear dark yellow with significantly increased surface roughness.This change not only enhances the mechanical properties of the fibers but also creates ideal conditions for subsequent bonding with the PE matrix.More in-depth characterization results (Figures 2g-i) reveal the microstructural changes of the material:FT-IR spectra show a significant reduction in the peaks at 1734cm⁻¹ (hemicellulose characteristic peak) and 1250cm⁻¹ (lignin characteristic peak)XRD analysis indicates an increase in the intensity of crystalline peaks and a decrease in half-peak width, indicating improved crystallinity of celluloseContact angle tests show that T-CBF’s hydrophobicity is enhanced, which is beneficial for interfacial bonding with the PE matrixSubsequently, the fibers were washed three times with distilled water and finally dried at 75℃ for 12 hours.Mechanical performance tests (Figure 3) demonstrate the effects of treatment:Tensile strength increased from 553.7±59.7MPa to 672.3±49.6MPa, an increase of 21%Toughness increased from 666.3J/m³ to 1067.2J/m³, nearly a 60% increaseYoung’s modulus increased by 30% The second step is the innovation of the 3D printing process.The research team selected PE tubes with an outer diameter of 2mm and an inner diameter of 1mm as the carrier material for the matrix, filling the treated bamboo fibers into them and optimizing the process using an FDM printer.

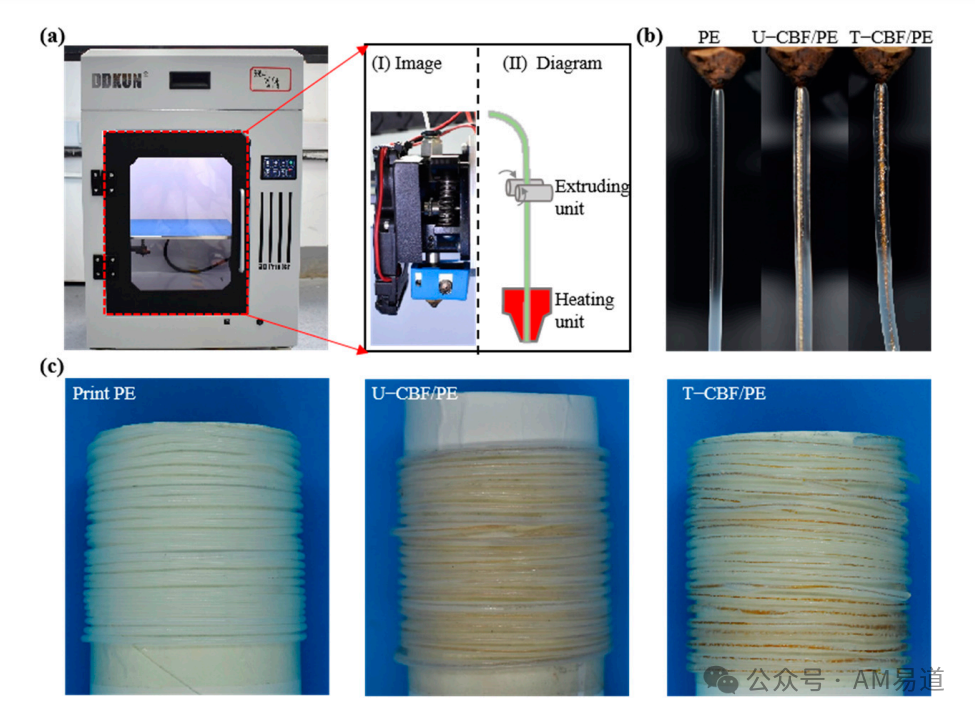

The second step is the innovation of the 3D printing process.The research team selected PE tubes with an outer diameter of 2mm and an inner diameter of 1mm as the carrier material for the matrix, filling the treated bamboo fibers into them and optimizing the process using an FDM printer. As shown in Figure 4, the entire printing system includes an extrusion unit and a heating unit, achieving ideal wetting of the bamboo fibers by the PE matrix through precise control of process parameters (Table 1):Printing speed: 5, 10, 15mm/sNozzle diameter: 0.8mmNozzle temperature: 190℃Heated bed temperature: 50, 60, 70℃

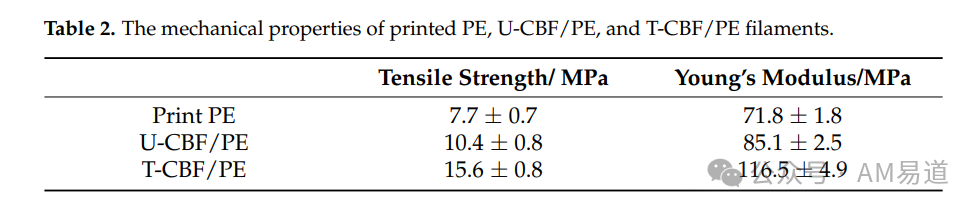

As shown in Figure 4, the entire printing system includes an extrusion unit and a heating unit, achieving ideal wetting of the bamboo fibers by the PE matrix through precise control of process parameters (Table 1):Printing speed: 5, 10, 15mm/sNozzle diameter: 0.8mmNozzle temperature: 190℃Heated bed temperature: 50, 60, 70℃ Amazing performance improvement: from micro-mechanisms to macro-characterizationThe performance tests of the composite material filaments (Figures 5 and Table 2) demonstrate significant performance improvements:

Amazing performance improvement: from micro-mechanisms to macro-characterizationThe performance tests of the composite material filaments (Figures 5 and Table 2) demonstrate significant performance improvements: The tensile strength of T-CBF/PE reached 15.6±0.8MPa, which is 2.03 times that of pure PE (7.7±0.7MPa); while Young’s modulus increased to 116.5±4.9MPa, a 62% increase over pure PE.

The tensile strength of T-CBF/PE reached 15.6±0.8MPa, which is 2.03 times that of pure PE (7.7±0.7MPa); while Young’s modulus increased to 116.5±4.9MPa, a 62% increase over pure PE. Interfacial analysis (Figure 6) reveals the micro-mechanisms behind the performance improvements:

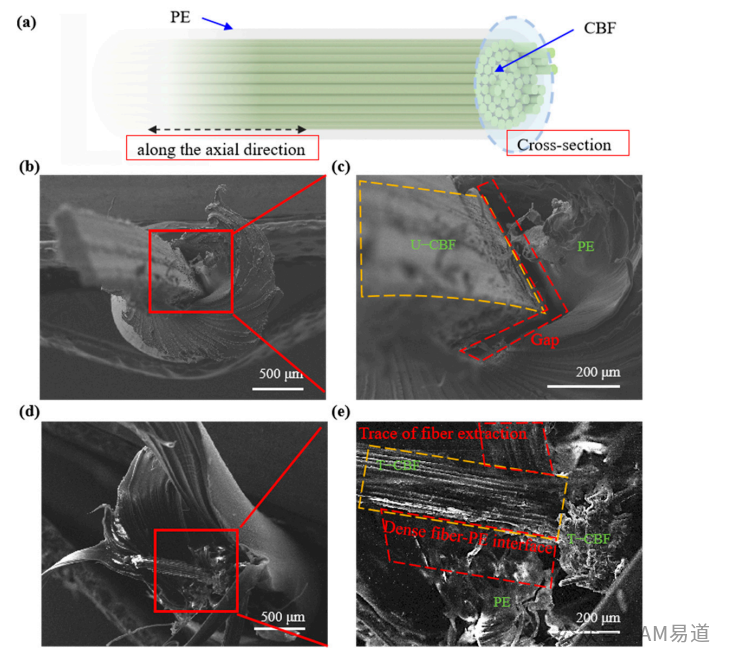

Interfacial analysis (Figure 6) reveals the micro-mechanisms behind the performance improvements: A dense interfacial structure forms between T-CBF and PE, with the fiber surface covered by a uniform PE layer, ensuring effective stress transfer.The performance tests of the 3D printed samples (Figures 7 and Table 3) are equally excellent:

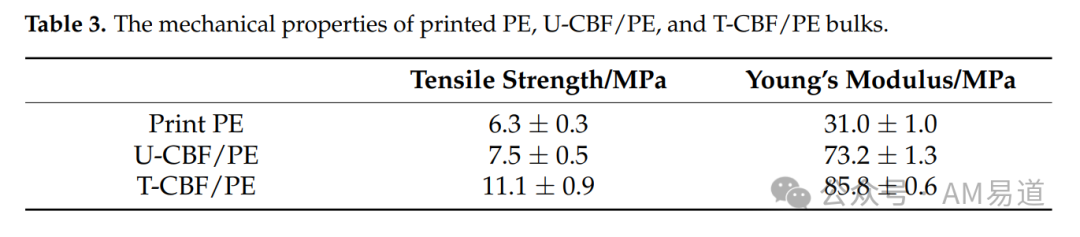

A dense interfacial structure forms between T-CBF and PE, with the fiber surface covered by a uniform PE layer, ensuring effective stress transfer.The performance tests of the 3D printed samples (Figures 7 and Table 3) are equally excellent: The tensile strength of T-CBF/PE printed parts reached 11.1±0.9MPa, a 77% increase over pure PE; Young’s modulus reached 85.8±0.6MPa, an increase of 1.76 times

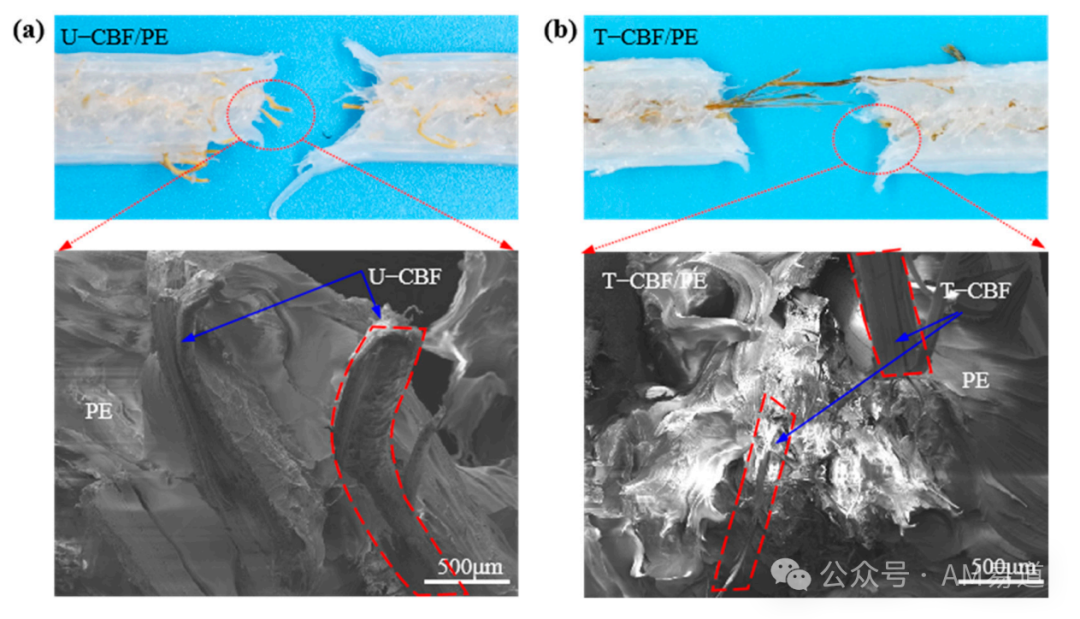

The tensile strength of T-CBF/PE printed parts reached 11.1±0.9MPa, a 77% increase over pure PE; Young’s modulus reached 85.8±0.6MPa, an increase of 1.76 times Fracture surface analysis (Figure 8) shows that T-CBF/PE composites exhibit more fiber pull-out and plastic deformation upon fracture, indicating that at the interface between T-CBF and PE:The micro-roughness of the fiber surface closely adheres to the PE matrix, ensuring efficient stress transfer from the matrix to the fiber, which may be the micro-foundation for the excellent performance of the material.

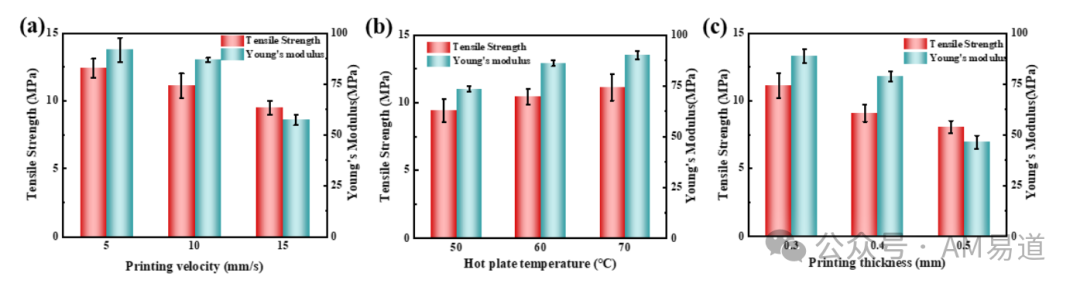

Fracture surface analysis (Figure 8) shows that T-CBF/PE composites exhibit more fiber pull-out and plastic deformation upon fracture, indicating that at the interface between T-CBF and PE:The micro-roughness of the fiber surface closely adheres to the PE matrix, ensuring efficient stress transfer from the matrix to the fiber, which may be the micro-foundation for the excellent performance of the material. Research on process parameter optimization (Figures 9 and Table 4) reveals the impact of three key factors on performance:

Research on process parameter optimization (Figures 9 and Table 4) reveals the impact of three key factors on performance: Printing speed: Best performance achieved at 5mm/s (tensile strength 12.4±0.7MPa)Heated bed temperature: Best interlayer bonding at 70℃ (tensile strength 11.1±0.9MPa)Layer thickness: Best compaction effect at 0.3mm (tensile strength 11.1±0.9MPa)

Printing speed: Best performance achieved at 5mm/s (tensile strength 12.4±0.7MPa)Heated bed temperature: Best interlayer bonding at 70℃ (tensile strength 11.1±0.9MPa)Layer thickness: Best compaction effect at 0.3mm (tensile strength 11.1±0.9MPa) This research showcases to the world that through intelligent design and precise process control, renewable natural materials can compete with traditional materials in high-performance fields.This not only provides new possibilities for green materials in the additive manufacturing industry but also brings new inspiration to the entire field of materials science.The research team stated that they are advancing technology upgrades in two directions: one is to develop new printing equipment that can accommodate more fibers, and the other is to explore the synergistic effects of functional additives.With continuous optimization of technology and gradual improvement of the industrial chain, this innovative bio-based composite material is expected to shine alongside traditional fiber composites in industrial applications.The resilience and wisdom that bamboo has infused into Chinese culture for thousands of years, empowered by 3D printing, may inject new innovative momentum into global green manufacturing.

This research showcases to the world that through intelligent design and precise process control, renewable natural materials can compete with traditional materials in high-performance fields.This not only provides new possibilities for green materials in the additive manufacturing industry but also brings new inspiration to the entire field of materials science.The research team stated that they are advancing technology upgrades in two directions: one is to develop new printing equipment that can accommodate more fibers, and the other is to explore the synergistic effects of functional additives.With continuous optimization of technology and gradual improvement of the industrial chain, this innovative bio-based composite material is expected to shine alongside traditional fiber composites in industrial applications.The resilience and wisdom that bamboo has infused into Chinese culture for thousands of years, empowered by 3D printing, may inject new innovative momentum into global green manufacturing.

Source: AM Yidao

▼For more exciting recommendations, please follow us▼

▼For more exciting recommendations, please follow us▼

Bamboo Fiber Preparation | Bamboo Fiber Applications | Bamboo Fiber Industry

WeChat Official Account: Bamboo Fiber Industry Network

Long press the QR code to follow us↙ClickRead the original textto participate in bamboo fiber project investment cooperation

Long press the QR code to follow us↙ClickRead the original textto participate in bamboo fiber project investment cooperation