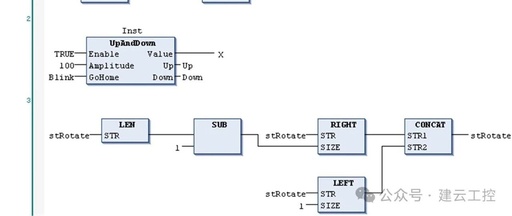

Intermediate PLC Programming: Mastering Finite State Machine Design for Complex Processes!

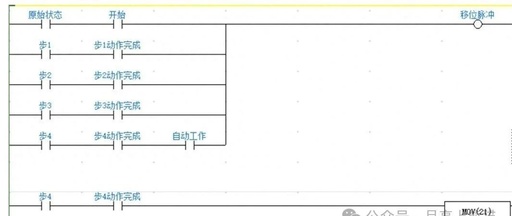

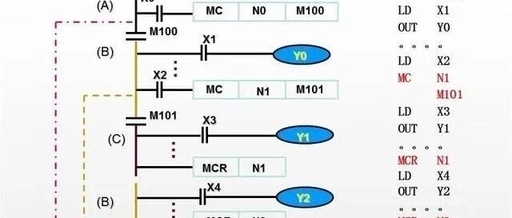

🔥 What Are the Limits of Traditional Logic Programming? The Magical Charm of Finite State Machines! Is your PLC program bloated due to complex process flows? Difficult to debug? Frequent failures? Is every upgrade like defusing a bomb? Today, I will reveal a programming tool known as Finite State Machine (FSM) that will help you … Read more