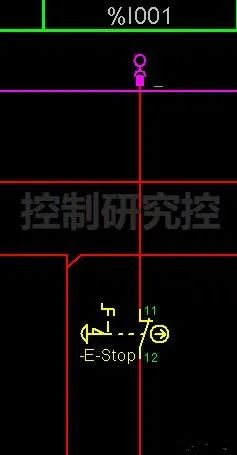

In PLC programming, the physical contact of the stop button is generally connected as normally closed, while in the program, it is written as normally open. This type of stop button only serves as a signal in this equipment.Why is the emergency stop in PLC programming opposite to that of a regular emergency stop button? In fact, writing it as normally open is not only for the emergency stop but also for thermal relays, temperature control, and other contacts with protective functions. The specific reasons are detailed below:First, the emergency stop button is also connected to the PLC’s DI point as a normally closed point: The above image shows part of the wiring diagram for the emergency stop button connected to the PLC! It can be seen that it is connected with normally closed contacts! The advantage of connecting with normally closed contacts is that when the circuit of the emergency stop button is broken, the program can immediately reflect this, or it can be said that it is equivalent to the emergency stop button being pressed, turning the normally closed contact into a normally open contact, thus achieving monitoring of the disconnection state!Next, let’s take a look at the PLC program:

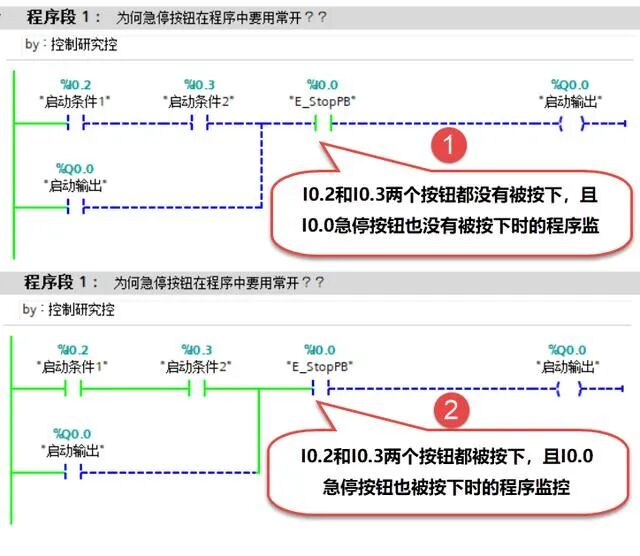

The above image shows part of the wiring diagram for the emergency stop button connected to the PLC! It can be seen that it is connected with normally closed contacts! The advantage of connecting with normally closed contacts is that when the circuit of the emergency stop button is broken, the program can immediately reflect this, or it can be said that it is equivalent to the emergency stop button being pressed, turning the normally closed contact into a normally open contact, thus achieving monitoring of the disconnection state!Next, let’s take a look at the PLC program: This segment of the program shows that the start condition 1 (I0.2) and start condition 2 (I0.3) are both connected to the PLC as normally open buttons, while the emergency stop button (E_StopPB) is connected to the PLC as a normally closed button! — From the circle ① in the image, it can be seen that when none of the three buttons are pressed, only E_StopPB is connected. When all three buttons are pressed, as shown in circle ②, the states of start conditions 1 and 2 are connected, while the state of E_StopPB shows disconnection!The difference in these two states explains why the emergency stop button is wired as normally closed at the PLC hardware level, while it is used as normally open in the PLC program! — This is because the digital input (DI) points of the PLC module are designed such that when the peripheral circuit is connected, the program internally shows connected, and when the peripheral circuit is disconnected, the program internally shows disconnected. This is due to the hardware circuit design of the PLC’s DI points!Additionally, because the emergency stop signal is a very important point, people utilize the hardware characteristics of the PLC’s digital input (DI) points to stipulate that the wiring of the emergency stop button should be connected as normally closed! — Because the normally closed point keeps the circuit continuously connected, the program must use normally open points, ensuring that when there is no emergency stop, the program logic can remain connected!Source: Internet, copyright belongs to the original authorPrevious Recommendations

This segment of the program shows that the start condition 1 (I0.2) and start condition 2 (I0.3) are both connected to the PLC as normally open buttons, while the emergency stop button (E_StopPB) is connected to the PLC as a normally closed button! — From the circle ① in the image, it can be seen that when none of the three buttons are pressed, only E_StopPB is connected. When all three buttons are pressed, as shown in circle ②, the states of start conditions 1 and 2 are connected, while the state of E_StopPB shows disconnection!The difference in these two states explains why the emergency stop button is wired as normally closed at the PLC hardware level, while it is used as normally open in the PLC program! — This is because the digital input (DI) points of the PLC module are designed such that when the peripheral circuit is connected, the program internally shows connected, and when the peripheral circuit is disconnected, the program internally shows disconnected. This is due to the hardware circuit design of the PLC’s DI points!Additionally, because the emergency stop signal is a very important point, people utilize the hardware characteristics of the PLC’s digital input (DI) points to stipulate that the wiring of the emergency stop button should be connected as normally closed! — Because the normally closed point keeps the circuit continuously connected, the program must use normally open points, ensuring that when there is no emergency stop, the program logic can remain connected!Source: Internet, copyright belongs to the original authorPrevious Recommendations

1. 2021 Latest Complete Electrical Engineering Question Bank (National Version)

2. Electrical Expert’s Private Tool Kit (Electrical Simulation Software + 16 Sets of Electrical Industry PPT)

3. Master Says: If You Don’t Know CAD, Don’t Expect to Become an Electrical Engineer (Includes CAD Software Package)

Click here if you like

Click here if you like Learn PLC and Electrical Courses for Free, click to read the original text

Learn PLC and Electrical Courses for Free, click to read the original text