Over the past two decades, additive manufacturing has made significant progress, evolving from a niche technology primarily used for prototyping into a manufacturing process with the potential to transform various business models and value propositions.

However, despite its immense potential, additive manufacturing excels in certain applications while underperforming in others. This paradox does not stem from inherent flaws in the technology itself, but rather from the complex interplay of factors such as material requirements, production scale, design freedom, and economic feasibility.

Let us explore why additive manufacturing performs exceptionally well in specific contexts while struggling in others.

Advantages of Additive Manufacturing

The primary advantage of additive manufacturing lies in its ability to produce highly complex, customized parts without the need for expensive molds, tooling, or complex setups. This design freedom, combined with low-volume production capabilities, makes additive manufacturing particularly suitable for applications where traditional manufacturing methods struggle. Its main advantages are reflected in:

Customization and Complexity

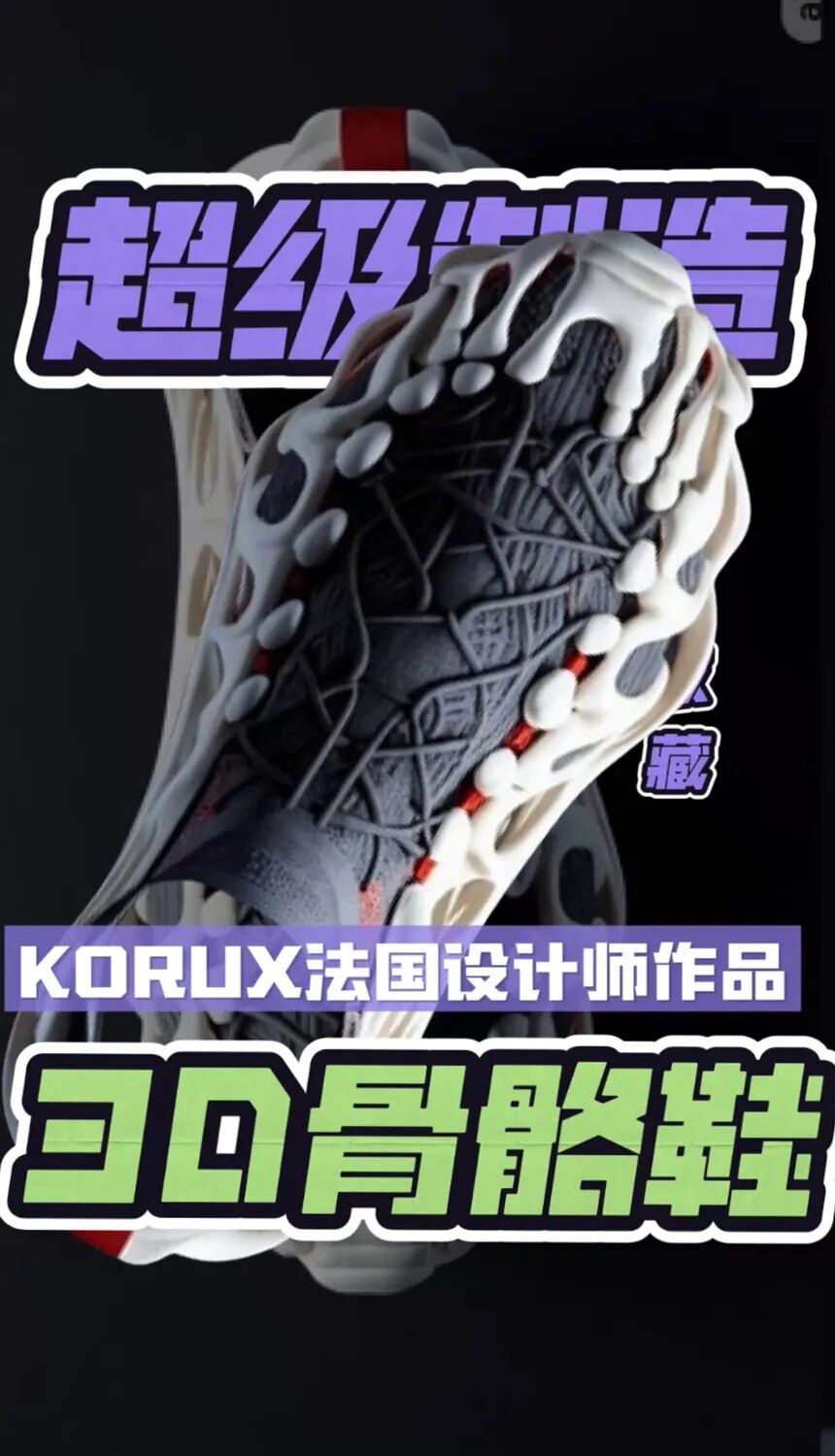

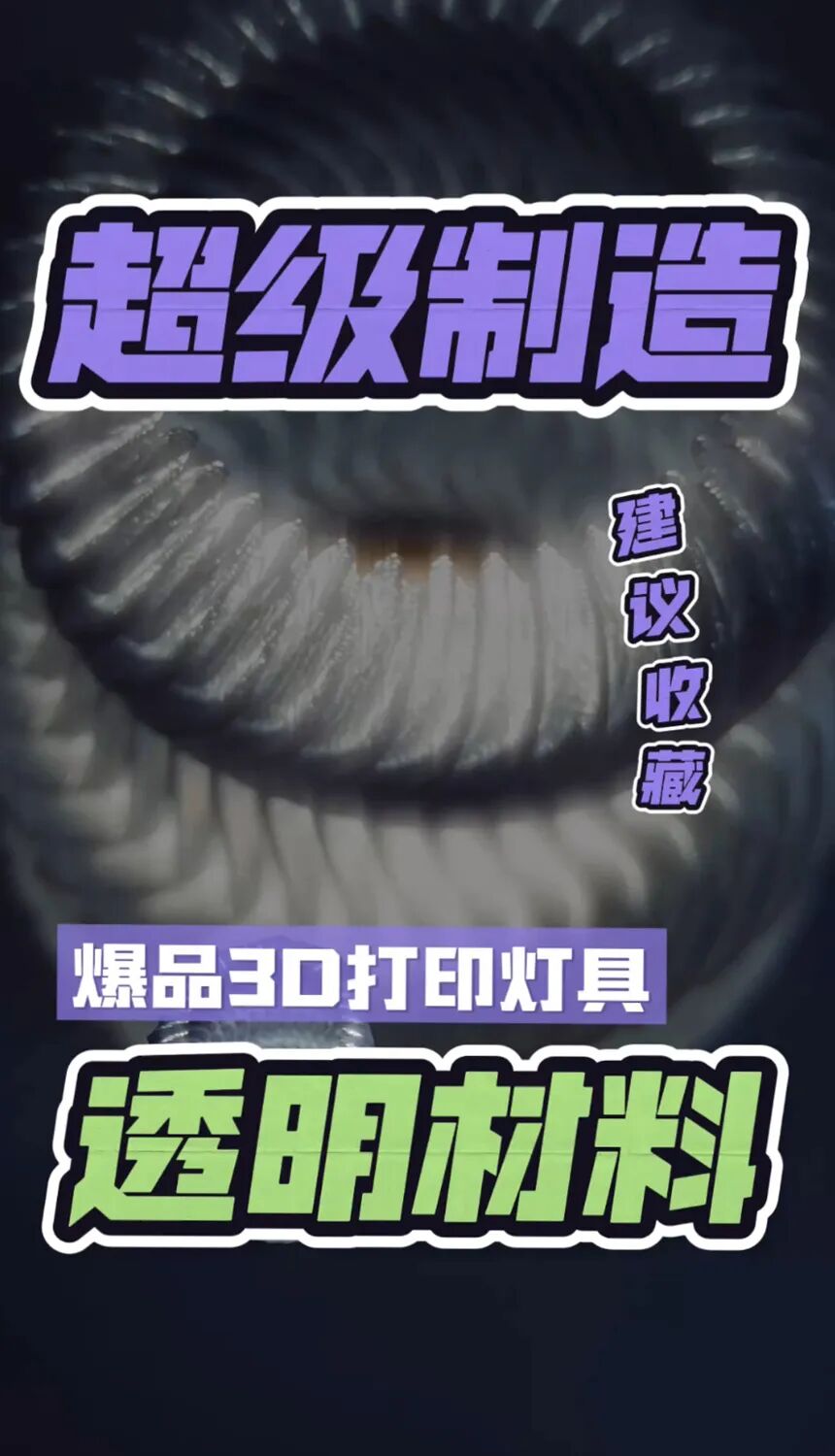

Additive manufacturing can produce parts with geometries that are extremely complex, which would be nearly impossible or prohibitively expensive to manufacture using traditional methods (such as injection molding or machining). This is particularly evident in industries such as aerospace, medical devices, and automotive, which often require complex parts that meet high-performance demands.

For example, in the aerospace industry, General Electric (GE) successfully developed a fuel nozzle for its LEAP engine using 3D printing technology in 2017. The nozzle, which traditionally required 20 separate parts, was reduced to just one part through additive manufacturing, resulting in improvements in both performance and cost. The complex internal geometry of the part (which helps improve fuel flow and cooling) would be extremely difficult to achieve using traditional methods.

Similarly, in the medical field, additive manufacturing has revolutionized the production of customized prosthetics, implants, and surgical guides. The ability to tailor devices based on a patient’s unique anatomical structure using CT scans or MRIs provides a level of personalization that traditional manufacturing cannot achieve.

Rapid Prototyping and Iteration

The iterative nature of additive manufacturing also makes it an excellent tool for rapid prototyping. This is especially valuable in industries where product design evolves quickly or requires continuous improvement, such as consumer electronics development or automotive design.

Additive manufacturing shortens the time from concept to physical prototype, allowing for faster testing, feedback, and modifications. It also eliminates the need for expensive tooling or molds, significantly lowering the barrier to trying new designs. For instance, automotive companies like Ford and BMW use 3D printing technology to quickly produce prototypes of vehicle parts, thereby shortening development cycles and accelerating the time to market for new models.

Supply Chain Flexibility

In the event of supply chain disruptions, additive manufacturing offers invaluable flexibility. During the COVID-19 pandemic, when traditional manufacturing sources could not meet demand, many manufacturers turned to 3D printing to produce critical medical supplies such as face shields, ventilator parts, and personal protective equipment.

Moreover, additive manufacturing supports decentralized production, enabling on-demand manufacturing close to the end user. This can be a game-changer for industries facing long lead times and high transportation costs. For example, aerospace companies have used additive manufacturing to produce spare parts in remote locations or military operation sites, reducing reliance on global supply chains and associated risks.

Disadvantages of Additive Manufacturing

Despite these compelling advantages, additive manufacturing is not a panacea. There are limitations that prevent it from being an ideal choice for widespread adoption, particularly in high-volume production environments or for parts requiring specific material properties. Some key areas where additive manufacturing faces challenges include:

Material Limitations

Although significant advancements have been made in material science for additive manufacturing, it still faces notable limitations compared to traditional manufacturing processes. For instance, metals like titanium and aluminum are commonly used in additive manufacturing, but their material properties may not always match those of similar materials produced through traditional methods such as casting or forging.

The thermal performance, strength, fatigue resistance, and surface finish of 3D printed metal parts often fall short of requirements in critical applications. This is why additive manufacturing is less frequently used in heavy industries, such as the production of large-volume automotive engine blocks or civil engineering structural components. In these cases, traditional methods like die casting or machining still dominate, as they can handle a wider range of materials and offer superior mechanical properties.

Speed and Cost at Scale

While additive manufacturing excels at producing low-volume, complex parts, it struggles when scaling up to high-volume production. Additive manufacturing processes, particularly metal 3D printing, are often slower and more expensive per part compared to traditional methods like injection molding or stamping.

For example, once a mold is made, a plastic part can be produced quickly and at low cost through injection molding, whereas 3D printing the same part may take hours or even days, depending on its size and complexity. In traditional methods, the cost per part decreases as production volume increases, while the cost per part in additive manufacturing remains relatively stable after exceeding a certain low-volume threshold. This makes additive manufacturing a poor choice for applications where economies of scale are critical.

In the automotive industry, for instance, thousands of identical parts are required. The high initial setup costs and slower speeds of additive manufacturing mean that unless the design involves significant complexity or customization, traditional manufacturing methods are typically more cost-effective.

Surface Finish and Post-Processing

Although additive manufacturing can produce complex geometries, the surface finish of parts often requires post-processing. Depending on the technology used (whether DED, SLS, or FDM), parts may exhibit visible layer lines, rough textures, or require additional finishing steps such as support removal, sanding, polishing, or coating.

This issue is particularly critical in industries where surface finish is paramount, such as consumer electronics or medical devices, where even minor defects can affect functionality or aesthetics. In these cases, the need for post-processing may offset some of the advantages of additive manufacturing, especially in terms of time and cost.

Value Proposition in Different Business Models

The success or failure of additive manufacturing often depends on how well it aligns with the business models of the industries in which it is applied. In certain fields, the advantages of additive manufacturing—customization, design freedom, and rapid prototyping—align perfectly with business needs. In other areas, traditional manufacturing models based on mass production and economies of scale still dominate.

Mass Customization vs. Low-Volume Manufacturing

For industries where low-volume production or customization is critical, additive manufacturing offers a compelling value proposition. For example, in medical device manufacturing, additive manufacturing allows for the creation of patient-specific implants and prosthetics, which aligns well with the trend towards personalized medicine. The aerospace and defense industries are similar, often requiring unique parts or small batch production.

These industries benefit from the flexibility and design freedom offered by additive manufacturing, even if the process is more expensive than traditional mass manufacturing. The higher cost per part can often be justified by the added value brought by customization, functionality, and performance.

Supply Chain Disruptions and On-Demand Production

Additive manufacturing’s ability to localize production and manufacture parts on demand makes it a powerful tool for industries facing supply chain disruptions or logistical challenges. Companies adopting this model are shifting from just-in-time inventory methods to more decentralized approaches.

For instance, spare parts in aerospace or military applications can be produced on-site using 3D printing, reducing the need for large inventories and minimizing downtime caused by parts shortages. For companies with extensive global supply chains, this ability to produce critical parts on demand offers significant advantages in cost reduction and supply chain risk mitigation.

Batch Production of Simple, High-Volume Parts

In industries that require large quantities of simple, identical parts, additive manufacturing struggles to provide any substantial benefits. In batch production, the economics of additive manufacturing become unfavorable, as unit costs typically decrease with increased production scale.

For example, producing millions of simple plastic bottles or caps through injection molding is an ideal task for companies like Procter & Gamble or Unilever. While the initial cost of injection molds may be high, once the molds are made, the production speed and unit costs are significantly lower than 3D printing. A mold can quickly produce hundreds of thousands of parts, with unit costs far below those of using additive manufacturing to print the same parts.

Additionally, the surface finish and consistency of injection-molded parts typically exceed those of 3D printed parts, which often require additional time and cost for post-processing. In batch production, the relatively slow speed and higher material costs of additive manufacturing make traditional methods a superior value in both cost and output.

Low-Precision Industrial Parts

In certain industrial applications where precision requirements are not high, additive manufacturing may not be able to deliver the necessary performance at a competitive cost. Additive manufacturing excels in situations requiring high precision or parts with geometries too complex to be manufactured using traditional methods, but for simple parts that only need to meet basic mechanical requirements, the technology may fall short.

A typical example is the manufacturing of low-precision industrial parts, such as certain structural components used in engineering machinery or agricultural equipment. These parts may need to meet basic strength and durability standards, but they do not require the kind of complex design or customization that additive manufacturing offers.

For these parts, traditional manufacturing methods such as forging, stamping, or casting are more cost-effective. These processes can produce durable, simple parts at a cost far lower than 3D printing. In the case of cast parts, material costs and production times are often lower, and the ability to produce parts in larger quantities makes these processes more economical for industries that prioritize sturdiness over complexity.

Strategic Approach

The key to understanding why additive manufacturing excels in some applications while falling short in others lies in matching the technology to the specific needs of the business.

Additive manufacturing is not a one-size-fits-all solution but a highly specialized tool that offers unique advantages in specific contexts. Industries that require customization, complexity, and rapid prototyping are well-suited for adopting additive manufacturing, while those focused on high-volume, cost-sensitive production still rely on traditional manufacturing technologies. It will always coexist with traditional manufacturing technologies and effectively complement them.

@ 3D Printing Insights

I am Xu Fanglei, a design professional with a PhD and a Fellow of the Royal Society of Arts in the UK, specializing in industrial design, additive manufacturing, and business models. Here, I will use my expertise and experience to take you deep into the world of 3D printing, sharing the latest industry trends, interpreting cutting-edge technologies, and discussing business applications.

END

END

Welcome to add the editor’s WeChatto learn about the latest trends in the 3D printing industry

Welcome to add the editor’s WeChatto learn about the latest trends in the 3D printing industry

About 3D Printing Technology

About 3D Printing Technology

To provide timely insights, technology trends, application scenarios, competitive strategies, and in-depth dynamics for practitioners in 3D printing and artificial intelligence, integrating industry insights from China, the US, and globally, we offer high-value information. We are passionate about 3D printing and welcome contributors from around the world.

Disclaimer:3D Printing Technology has no commercial cooperation, sponsorship, employment, or other interests with the companies mentioned in this article.3D Printing TechnologyImages and videos are sourced from the internet and are for auxiliary reading purposes only, with no commercial intent.All rights belong to the original authors. If there are any infringement issues, please contact the rights holders promptly, and we will delete them immediately. The copyright of the images in this article belongs to the copyright holders,3D Printing Technologywatermarks are automatically added for auxiliary reading and do not represent ownership of the images. For image usage, please consult the relevant copyright holders.3D Printing TechnologyThe article does not constitute any investment advice,3D Printing Technologyis not responsible for any direct or indirect losses caused by the use of the information in this article.