Nowadays, infrared sensor technology has become very mature, integrating into people’s daily lives and playing a significant role.

Before understanding infrared sensors, we should first understand what infrared rays, or infrared light, are.

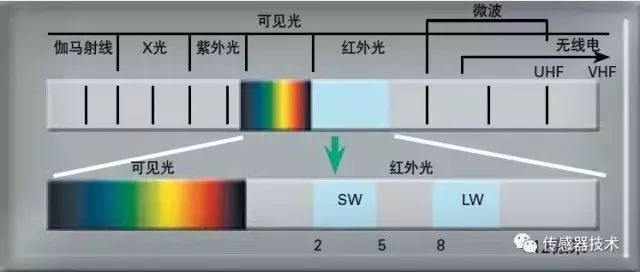

We know that light is a form of electromagnetic radiation, and based on human experience, the visible light spectrum ranges from 400nm (violet) to 700nm (red), which can be perceived by the human eye.

As shown in the figure, we refer to radiation with wavelengths between 760nm and 1mm, beyond red light, as infrared light. Infrared light is invisible to the naked eye, but we can still perceive it through some special optical equipment.

Infrared rays are a form of light that cannot be seen by the human eye, so they possess all the characteristics of light. However, infrared rays also have a very significant thermal effect. Any substance above absolute zero, which is -273°C, can emit infrared rays.

Therefore, simply put, an infrared sensor is a type of sensor that uses infrared rays as a medium for data processing.

Types of Infrared Sensors

Infrared rays are invisible to the human eye, so they possess all the characteristics of light. However, infrared rays also have a very significant thermal effect. Any substance above absolute zero, which is -273°C, can emit infrared rays.

According to the method of emission, infrared sensors can be divided into active and passive types.

Working Principle and Characteristics of Active Infrared Sensors

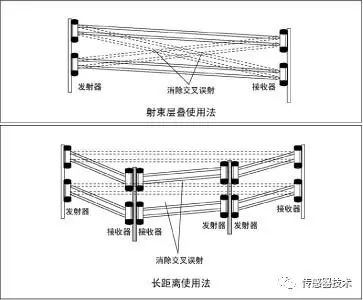

Active infrared sensors emit a modulated infrared beam from a transmitter, which is received by an infrared receiver, forming a security line composed of infrared beams. When obstructed by leaves, rain, small animals, snow, sand, or fog, it should not trigger an alarm; however, if a person or a similarly sized object obstructs it, an alarm will be triggered.

Active infrared detection technology primarily uses a one-to-one transmission and reception method, belonging to linear protection. It has evolved from the initial single beam to multiple beams, and can now also utilize dual transmission and reception to minimize false alarms, thereby enhancing the product’s stability and reliability.

Since infrared rays have good incongruence with environmental factors (they are not significantly affected by sounds, lightning, vibrations, various artificial light sources, and electromagnetic interference), and also have good congruence with target factors (only the target that blocks the infrared beam will trigger the alarm), active infrared sensors will be further promoted and applied.

Working Principle and Characteristics of Passive Infrared Sensors

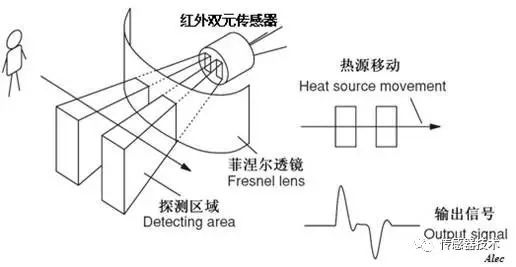

Passive infrared sensors work by detecting the infrared rays emitted by the human body. The sensor collects external infrared radiation, which is then focused onto the infrared sensor. Passive infrared sensors typically use pyroelectric elements, which release charges when they detect changes in temperature due to infrared radiation, resulting in an alarm after processing.

This type of sensor is aimed at detecting human radiation. Therefore, the radiation-sensitive elements must be very sensitive to infrared radiation with a wavelength of around 10μm. To be sensitive to human infrared radiation, the radiation surface is usually covered with a special filter, which significantly controls environmental interference.

Passive infrared sensors consist of two pyroelectric elements connected in series or parallel. The polarization directions of the two electrodes are opposite, causing the environmental background radiation to have nearly the same effect on both pyroelectric elements, canceling out the pyroelectric effect and resulting in no signal output from the detector.

Once an intruder enters the detection area, the human infrared radiation is focused through a lens and received by the pyroelectric element. However, the two pyroelectric elements receive different amounts of heat, resulting in different pyroelectric outputs that cannot cancel each other out, triggering an alarm after signal processing.

According to the method of energy conversion, infrared sensors can also be divided into photon-type and pyroelectric-type.

Photon Infrared Sensors

Photon infrared sensors work based on the photon effect of infrared radiation. The photon effect refers to the interaction between the photon flow in infrared radiation and the electrons in certain semiconductor materials when infrared rays strike them, changing the energy state of the electrons and causing various electrical phenomena.

By measuring the changes in the properties of electrons in the semiconductor material, we can determine the intensity of the corresponding infrared radiation. The types of photon detectors include internal photoelectric detectors, external photoelectric detectors, free carrier detectors, and QWIP (Quantum Well Infrared Photodetector) detectors.

The main characteristics of photon detectors are high sensitivity, fast response speed, and a high response frequency. However, their drawback is that their detection wavelength range is relatively narrow, and they generally operate at low temperatures (to maintain high sensitivity, they are often cooled to lower operating temperatures using liquid nitrogen or thermoelectric cooling methods).

Pyroelectric Infrared Sensors

Pyroelectric infrared sensors detect certain parameters by utilizing the thermal effect of infrared radiation, which causes changes in the temperature of the components. Their detection rate and response speed are not as good as those of photon-type sensors.

However, since they can be used at room temperature and their sensitivity is independent of wavelength, they have a wide range of applications. Pyroelectric infrared sensors that utilize the pyroelectric effect of ferroelectric materials have high sensitivity and have been widely used.

The pyroelectric effect occurs when certain insulating materials generate equal but opposite charges at both ends of the crystal as the temperature increases. This phenomenon, caused by thermal changes, is known as the pyroelectric effect. The crystals that can generate the pyroelectric effect are called pyroelectric materials, also known as thermoelectric elements. Common materials for thermoelectric elements include single crystals, piezoelectric ceramics, and polymer films.

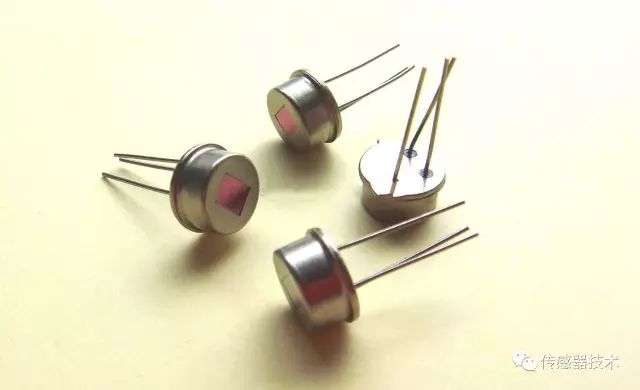

The structure of pyroelectric infrared sensors consists of four main parts:

① An aluminum substrate and field-effect transistors (FET) that form the circuit;

② Ceramic materials with pyroelectric effects;

③ Window materials that restrict the incident infrared wavelength;

④ A TO-5 type tube cap and tube base.

Since the detector elements have limitations such as short detection distances and difficulties in processing the signals obtained when used alone, infrared combinations are now often used for detection. An infrared combination consists of a pyroelectric infrared sensor, a lens, a measurement conversion circuit, and a sealed tube casing. The lens can expand the detection range and improve measurement sensitivity; the measurement conversion circuit can complete processes such as filtering and amplification; and the sealed tube casing can prevent false actions caused by external noise. This combination is small, cost-effective, and versatile, leading to widespread applications.

Applications of Infrared Sensors

From the current application situation, infrared sensors have the following advantages:

1. Environmental adaptability superior to visible light, especially in nighttime and adverse weather conditions;

2. Good concealment; they generally passively receive signals from targets, making them safer and more confidential than radar and laser detection, and less prone to interference;

3. The ability to recognize camouflaged targets is superior to visible light due to the infrared radiation characteristics formed by the temperature difference and emissivity difference between the target and the background;

4. Compared to radar systems, infrared systems are smaller, lighter, and consume less power;

Based on the aforementioned performance characteristics of infrared sensors, we can develop various types of infrared detectors.

Utilizing Its Optical Effect:

1. Photoconductive Detectors: Also known as photoconductive resistors. When a semiconductor absorbs sufficiently energetic photons, some carriers within transition from a bound state to a free state, thereby increasing the conductivity of the semiconductor. This phenomenon is known as the photoconductive effect. Photoconductive detectors made using the photoconductive effect can be divided into polycrystalline thin film types and single crystal types.

2. Photovoltaic Detectors: Mainly utilize the photoelectric effect of the p-n junction. Infrared photons with energy greater than the bandgap excite electron-hole pairs in the junction area and its vicinity. The existing junction electric field causes holes to enter the p-region and electrons to enter the n-region, creating a potential difference in the external circuit, resulting in voltage or current signals. Compared to photoconductive detectors, photovoltaic detectors have a background limited detection rate that is 40% larger, do not require an external bias electric field and load resistance, consume no power, and have high impedance.

3. Schottky Barrier Detectors: When metal and semiconductor contact, a Schottky barrier is formed. Infrared photons pass through the Si layer and are absorbed by PtSi, causing electrons to gain energy and transition to the Fermi level, leaving holes that cross the barrier into the Si substrate, where the electrons from the PtSi layer are collected, completing the infrared detection.

4. Quantum Well Detectors (QWIP): Superlattices are formed by artificially growing alternating layers of two semiconductor materials, creating energy band discontinuities at their interfaces, which restrict electrons and holes in low potential wells, thus quantizing energy levels to form quantum wells. Infrared detectors can be made based on the principle of electronic transitions in the energy levels of quantum wells. However, only the polarization vector perpendicular to the superlattice growth plane is effective in the incident radiation, leading to low photon utilization; the base state electron concentration in the quantum well is limited by doping, resulting in low quantum efficiency; the response spectrum range is narrow, and the low-temperature requirements are stringent.

Utilizing Its Thermal Effect:

1. Liquid Mercury Thermometers and Golay Cells: Utilize the thermal expansion and contraction effects of materials.

2. Thermocouples and Thermopiles: Utilize the thermoelectric effect, which generates a thermoelectric potential difference between different materials due to temperature gradients.

3. Quartz Resonator Non-Cooled Infrared Imaging Arrays: Utilize the principle of resonance frequency sensitivity to temperature for infrared detection.

4. Radiation Thermometers: Utilize the thermal sensitivity effect of materials’ resistance or dielectric constant—radiation causes temperature rise, changing the material’s resistance—used for detecting thermal radiation. Semiconductor resistance has a high temperature coefficient and is thus most commonly used; radiation thermometers are often referred to as “thermistors.”

Additionally, with the emergence of high-temperature superconductors, superconducting detectors that utilize the sharp change in resistance near the transition temperature have gained attention. If room-temperature superconductivity becomes a reality, it will be one of the most notable types of detectors in the 21st century.

5. Pyroelectric Detectors: Certain crystals, such as triglycine sulfate and barium niobate, when exposed to infrared radiation, increase in temperature, causing spontaneous polarization intensity changes, resulting in a small voltage generated between the two outer surfaces of the crystal perpendicular to the spontaneous polarization direction, allowing for the measurement of the power of infrared radiation.

According to application functions and locations, infrared sensors can be broadly divided into the following categories:

Radiation and Spectral Measurement

This type of measuring instrument has a wide range of applications, such as ground radiation intensity meters based on mid-infrared radiation measurement, which can be used for observing climate changes like global warming; infrared space telescopes based on far-infrared radiation measurement, which can be used for astronomical observations of cosmic bodies; and meteorological satellites equipped with infrared spectral scanning radiometers, which can perform meteorological observations and analyses of cloud layers. In industrial and mining enterprises, infrared thermometers based on radiation measurement and infrared analyzers based on infrared spectral measurement are widely used.

Search and Tracking Systems

The short-range air-to-air missiles carried by fighter jets use infrared tracking systems, which are based on the electromagnetic radiation waves emitted by targets within the infrared spectrum to search for and track infrared targets, determining their spatial positions and tracking their trajectories.

The image quality of infrared search trackers depends on the spatial resolution related to pixel size and pixel count. In other words, the higher the number of pixels, and the smaller the pixel size, the clearer the displayed image, allowing for greater search distances.

French company Sofradir, which specializes in MCT (Mercury Cadmium Telluride) cooled infrared detection technology, recently launched a high-performance infrared search and tracking system based on 10μm pixel MWIR (Mid-Wave Infrared), which can effectively identify, distinguish, and locate small targets up to 10km away, regardless of whether it is day or night, even in smoky or foggy environments.

Thermal Imaging Systems

Thermal imaging cameras utilize infrared detectors and optical imaging lenses to capture the infrared radiation energy distribution patterns of the target being measured, reflecting them onto the light-sensitive elements of the infrared detector to obtain infrared thermal images, which correspond to the thermal distribution field of the object’s surface. In simple terms, thermal imaging cameras convert the invisible infrared energy emitted by objects into visible thermal images. The different colors on the thermal image represent different temperatures of the measured object.

Any object with a temperature will emit infrared rays, and thermal imaging cameras receive the infrared rays emitted by objects, displaying the temperature distribution of the object’s surface through colored images. They can identify temperature anomalies based on slight temperature differences, thus serving a maintenance function. They are commonly referred to as infrared thermal cameras.

Thermal imaging cameras were initially developed for military purposes but have rapidly expanded into the civilian industrial field in recent years. Their applications are very broad, wherever there are temperature differences.

For example: in the construction field, they can check for hollow spots, defects, tile detachment, moisture, thermal bridges, etc.; in fire protection, they can locate fire sources, determine the cause of accidents, and find injured individuals in smoke; in law enforcement, they can locate hidden individuals at night; in the automotive manufacturing field, they can check the performance of tires, heating wires in air conditioning, engines, exhaust systems, etc.; in medicine, they can detect the effects of acupuncture, and early detection of nasopharyngeal cancer, breast cancer, and other diseases; in electricity, they can inspect wires, connections, circuit breakers, substations, etc.

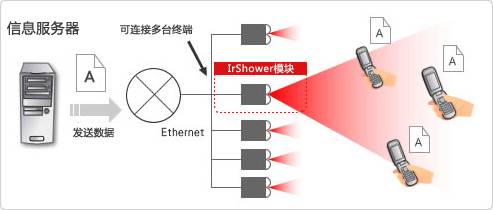

Infrared Communication Systems

This system uses modulated infrared radiation beams to transmit encoded data, which is then converted into electrical signals by silicon photodiodes, enabling short-distance communication. It has the advantage of not interfering with the normal operation of other nearby devices, making it particularly suitable for indoor communication in densely populated areas. Additionally, this communication system has low power consumption, low cost, and is safe and reliable.

Others

Infrared sensing technology is also widely used in access control and alarm systems, lighting control, fire detection, detection of toxic and harmful gas leaks, infrared ranging, heating and ventilation, and other comprehensive application scenarios. At the “SENSOR+TEST” exhibition held in Nuremberg, Germany, French company ULIS showcased its latest infrared thermal sensor array product Micro80P, which employs the latest on-chip innovative technologies (such as I2C standard interfaces, low power management, etc.).

This sensor array is based on highly reliable amorphous silicon technology, with a sensitivity of up to 80×80 pixels, far exceeding the capabilities of single or four-element thermal sensors currently used in motion detectors, significantly enhancing the capabilities of industrial-grade infrared thermal detection sensors.

This product can not only detect temperature points or temperature surfaces and detect motion but can also count, locate, and classify target or human activities. For example, in HVAC scenarios, it can count the number of people in a room and measure the wall temperature, thereby automatically fine-tuning the indoor heating and air conditioning systems for maximum energy savings.

Development of Infrared Sensors

With the improvement of scientific and technological levels, the development of computer microprocessor technology, the enhancement of modern digital signal processing technology, the introduction of new semiconductor materials, and the advancement of manufacturing processes, infrared sensors have developed rapidly in recent years.

In recent years, the development trends of infrared sensors are mainly reflected in the following four aspects:

First, the adoption of new materials and processing technologies has improved the infrared detection rate, increased the response wavelength, shortened the response time, enhanced pixel sensitivity and density, improved anti-interference performance, and reduced production costs. For example, Pyreos and Irisys have launched a new type of pyroelectric sensitive technology that combines thin films and ceramics, allowing for the realization of sensitive elements in an array.

Second, the large-scale and multifunctional nature of sensors. With the development of microelectronics technology and the continuous expansion of application fields, infrared sensors are evolving from small, single-function devices to large-scale, multifunctional ones.

For example, large infrared sensors (16×16 to 64×64 pixels) developed abroad can not only measure temperature fields but also obtain advanced human detection functions that small infrared sensors do not have (such as accurately locating individuals in space, even when they are inactive) or large area security monitoring functions, making them very suitable for applications in home automation, healthcare, and security protection.

Additionally, the development of new multispectral sensors has greatly improved the functionality of infrared imaging arrays.

Third, the intelligence of sensors. New intelligent infrared sensors typically have multiple microprocessors built-in, equipped with advanced digital signal processing or compensation functions such as Fourier transforms and wavelet transforms, self-diagnostic capabilities, and bidirectional digital communication, greatly enhancing the stability, reliability, signal-to-noise ratio, and convenience of sensors.

Fourth, further miniaturization and integration of sensors. With the adoption of on-chip integration technology (including blind element replacement, non-uniformity correction, partial image processing functions, etc.) and other new device structures and manufacturing processes, driven by MEMS (Micro-Electro-Mechanical Systems) and even NEMS (Nano-Electro-Mechanical Systems) based on nanotechnology, the size of infrared sensors has significantly decreased, power consumption has greatly reduced, and integration has improved significantly.

Due to the superior performance of infrared sensors, many mainstream instrument research institutions and manufacturers are increasingly investing in their research and development.

– END –

Source: Sensor Technology

END

Hot Articles (Scroll Up to Read)

Recommended Articles | Zhou Yitian: Bearing Fault Diagnosis Model Based on Feature Expansion CapsNet

Recommended Articles | Wang Hong: Embedded Online Monitoring Technology for Foreign Avionics Systems

Recommended Articles | Wang Bin: Three-Dimensional Measurement of Ice Formation Based on Line Structured Light Scanning

Recommended Articles | Jia Funian: Design and Verification of High-Altitude Inlet Device for Turbo Shaft Engine

Recommended Articles | Yan Bo: Research on Oxygen Partial Pressure of Al2O3 High-Temperature Insulating Film Based on Dual Ion Beam Sputtering

Recommended Articles | Wang Hong: Testing Technology System Architecture for Civil Aircraft Electromechanical Systems

Recommended Articles | Zhang Shuai: Research on NARX Neural Network-Assisted Integrated Navigation Methods

Recommended Articles | Wu Zhen: Design of Autonomous Route Planning Platform for Drones

Recommended Articles | Zhao Xiaoping: Gearbox Fault Diagnosis Method Based on Information Fusion and CNN

Recommended Articles | Shi Yucheng: Analysis of Shock Wave Pressure Measurement and Sensor Technology Status

Recommended Articles | Meng Chihua: Research on Arc Simulation Based on Aviation AC Fault Arc Standards

Recommended Articles | Wu Zheming: Correlation Analysis of Component Failures in Multi-Electric Aircraft Starter Generator Systems Based on DEMATEL

Recommended Articles | Lü Zuopeng: Application of HHT Time-Frequency Analysis Method Based on Wavelet Packet and EMD in Bearing Fault Diagnosis of Aviation Test Equipment

Recommended Articles | Wang Hong: Intelligent Testing and Monitoring Technology for Aviation Onboard Systems

Recommended Articles | Xin Wenhui: Dual Closed-Loop Temperature Control System for Semiconductor Lasers

Recommended Articles | Li Dapeng: In-Situ Detection System for Atmospheric Parameters Based on Airship and Experiments

Recommended Articles | Jiao Xiaofeng: Overview of CO2 Detection Technology Based on TDLAS

Recommended Articles | Chen Haiming: Online Calibration Method for Magnetic Sensors in Backup Attitude Systems

Recommended Articles | Ren Dantong: Dual Light Fusion Workshop Personnel Behavior Recognition Method for Smart Factories

Recommended Articles | Li Shuhao: Research on Integrated Monitoring Technology in Bearing Fault Diagnosis

Recommended Articles | Zhuo Li: Multi-Attribute Collaborative Recognition Method for Pedestrians Based on ResNet50 and Channel Attention Mechanism

Recommended Articles | Liang Minjian: Research on Mechanical Fault Classification of Escalators Based on One-Dimensional Convolutional Neural Networks

Recommended Articles | Hou Qilin: Remaining Useful Life Prediction of Aviation Lithium Batteries Based on Indirect Health Indicators and Echo State Networks

Recommended Articles | Chen Peng: An End-to-End Natural Scene Text Detection and Recognition Model

Recommended Articles | Hou Feng: Remote Sensing Image Retrieval Based on Deep Feature Dictionary Learning and Largevis

Recommended Articles | Wang Xinyao: Global Inertial Navigation and Integrated Navigation Methods Based on Earth Coordinate System

Recommended Articles | Chen Lijing: Fault Diagnosis of Aviation Inverters Based on Multi-Class SVM

Recommended Articles | Li Mingfei: Discussion on Image Enhancement and Flow Field Density Processing of Blade Pattern Shadow Test

Recommended Articles | Liu Qiuyu: Flexible Pressure Sensors Based on Capacitive-Resistive Conversion Principles

Recommended Articles | Li Lei: Research on Data-Driven Fault Prediction Methods

Recommended Articles | Yan Junjie: Automatic Precision Assembly Technology for Satellite Antenna Modules Based on Machine Vision

Recommended Articles | Yao Yanling: Research on Surge Diagnosis Model of Aviation Engines Based on CNN-Seq2Seq

Recommended Articles | Guan Li: Overview of Electric Static Hydraulic Actuation Technology for Aircraft Flight Control Actuation Systems

Recommended Articles | He Yunze: Analysis of Acoustic Emission Signals of Power Devices in Inverter Circuits

Recommended Articles | Xie Li: Defect Detection of Circuit Board Components Based on Improved YOLOv4 Network

Recommended Articles | Wang Yizhou: Short Video Fingerprint Extraction Based on R(2+1)D Twin Networks

Recommended Articles | Han Han: Overview of No-Reference Image Quality Assessment Based on Deep Learning

Recommended Articles | Wang Jiulong: Research on Fatigue Testing Technology of Helicopter Tail Rotor Blades

Recommended Articles | Sun Weihong: Research on Portable ECG Monitoring Systems Based on Flexible Electrodes

Recommended Articles | Zhang Meiju: Research Status and Development Trend of Ceramic Substrate Thin Film Thermocouples

Recommended Articles | Ouyang Lin: Fatigue Driving Detection Algorithm Based on Driver’s Facial Temporal Data

Recommended Articles | Zhang Wenli: Multi-Target Tracking Algorithm Based on Improved Transformer and Anchor-Free Network

Recommended Articles | Liu Guanjun: Research Progress on Silicon-Based and Graphene-Based Resonant Pressure Sensors

Recommended Articles | Jiang Chao: Overview of Image-Based Battlefield Situation Awareness Technology for Drones

Recommended Articles | Zhang Feiyang: Overview of Alertness Detection Research Based on Physiological Signals

Recommended Articles | Qiu Fang: Research on Autonomous Management Software Architecture for Spacecraft Control Systems in Deep Space Exploration

Recommended Articles | Wang Yanshan: Research Progress on Flexible Pressure/Strain Sensors Based on Graphene

Recommended Articles | Wang Hong: Research on Testing Technology System Architecture for Civil Aircraft

Recommended Articles | Liu Yawei: Research Overview of Digital Twins for Structural Health Management of Aircraft

2021 Collection of Excellent Papers in Computer and Automation Technology

2021 Collection of Excellent Papers in Aerospace

2020 Collection of Excellent Papers in Aerospace

2020 Collection of Excellent Papers in Computer and Automation Technology