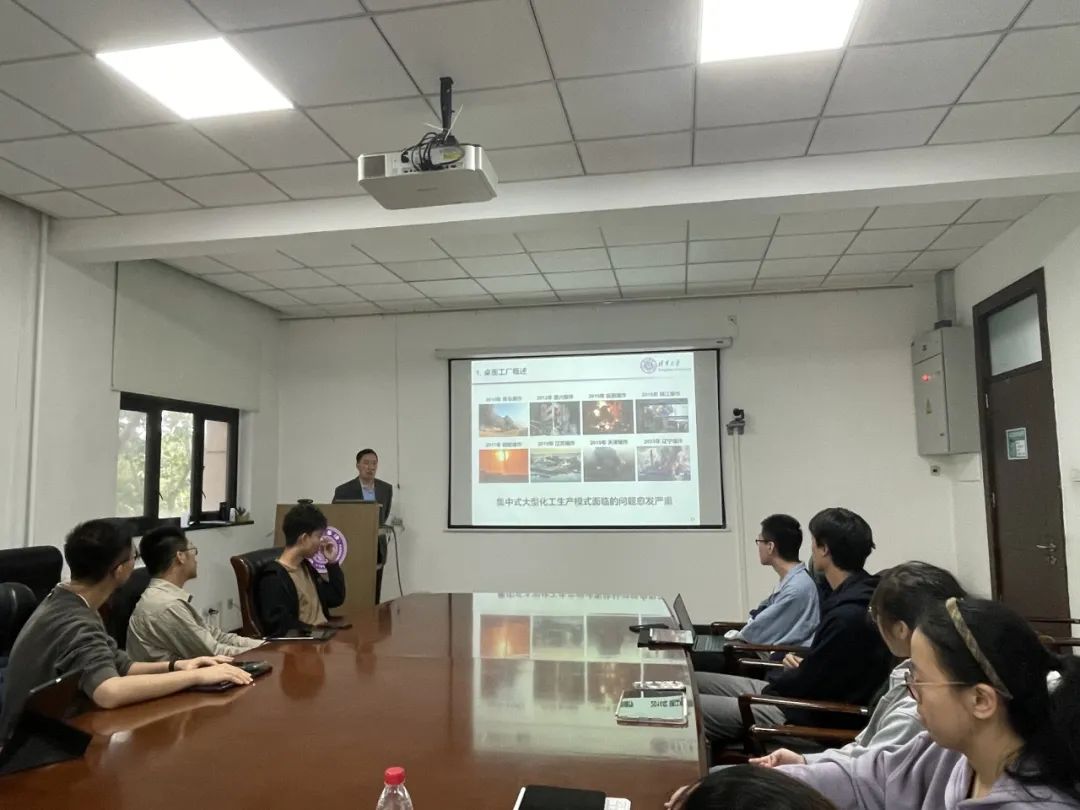

On October 18, 2024, the Micro Salon of the Tanwei Academy welcomed its 18th lecture for the 2024-2025 academic year, marking the 335th lecture since its inception. The theme of this micro salon was “Desktop Factory: Transformative Production Paradigms,” presented by Professor Luo Guangsheng from the Department of Chemical Engineering.

In this micro salon, the professor briefly reviewed the questions raised by students during the previous session on the same theme and the questions posed by attendees for this session. Using this as a starting point, he began his introduction to the emerging and transformative production method of the desktop factory.

First, the professor introduced the concept and development of the desktop factory. The desktop factory is not merely about shrinking a factory to a desktop; rather, it involves miniaturizing the factory to adapt to different production needs and environments. The desktop factory is characterized by its small scale, compact footprint, low investment, ease of mobility and deployment, and high production efficiency, which helps change centralized production methods, reduce production costs, and promote industrial upgrading.

To understand the desktop factory’s role in transforming production methods, one must first grasp the current state of industrial production. Currently, industrial production is divided into two modes: centralized manufacturing and discrete manufacturing. The professor discussed the applications of these two production modes in industrial production and briefly analyzed their impacts on energy structure changes and carbon emissions.

The centralized manufacturing model concentrates raw materials, personnel, and equipment in one location for production, such as in oil refining and steel manufacturing processes. The advantage of this model is the intensive utilization of labor, capital, and energy, improving production efficiency. However, the centralized manufacturing model also brings issues of carbon emissions and energy consumption, particularly in transportation. The professor cited the carbon emission distribution in American society as an example to help students understand.

The discrete manufacturing model breaks down the production process into multiple independent segments, each focusing on a specific task, such as automobile manufacturing and computer production. The advantage of this model is that it allows for rapid updates and customized production to meet market demands. The professor noted that the discrete manufacturing model has been widely applied in the automotive and computer industries, driving rapid development in these sectors.

Next, the professor focused on the chemical industry and discussed the industrial transformation within this sector. Currently, the production philosophy in the chemical industry is shifting from pursuing scale to pursuing efficiency, with a transition from centralized to decentralized manufacturing. The miniaturization and micro-manufacturing development in the chemical industry has become an important trend, which has significant implications for the sustainable development of the chemical industry. The miniaturization of chemical processes helps reduce accident risks, enhance reaction rates and efficiency, achieve precise control, and enable distributed manufacturing. The desktop factory is an application of micro-chemical technology.

The professor mentioned that to achieve such transformation, it is essential to develop miniaturized and integrated chemical equipment; utilize flow chemistry technology to explore new boundaries in chemical synthesis for more efficient reactions; leverage artificial intelligence technology to realize automated and intelligent production processes; and also focus on big data and algorithm technologies to optimize production processes and enhance efficiency. This will lead to the sustainable development of the chemical industry and further enhance the competitiveness of our industry.

Finally, the professor engaged in an interactive session with the students, who eagerly asked questions that the professor patiently answered.

Feedback from Participating Students

Yang Xuenan: The professor introduced us to the origin, specific characteristics, and future development of the “desktop factory,” providing a clear explanation of its transformative aspects. In the context of energy transition, we need to shift from the previous concept of large-scale production with large reactors to improve production efficiency, using micro-manufacturing as a new production paradigm to reduce carbon emissions and achieve green development.

Ling Jinfeng: Professor Luo explained the background, connotation, and specific application scenarios of the new concept of the desktop factory. As an important pathway for the transformation of chemical production paradigms, the micro-chemical technology represented by the desktop factory has extremely broad application prospects; the combination of high-throughput laboratories and flow chemistry demonstrates the application of big data and computer technology in the field of chemistry and chemical engineering. Professor Luo’s detailed explanation was very enlightening.

Yu Shanli: The transition from large-scale chemistry and beaker chemistry to micro-chemistry is not just a change in size and scale, but a change in thinking. Through Professor Luo’s clear and insightful report, I realized that micro-chemistry is not only the inevitable direction for the transformation of future chemical production methods but also a powerful tool for future scientific research.

Written by | Wu Moyan

Photography | Wu Moyan

Editing | Yao Jinhao

Review | Luo Guangsheng, Zhou Xirui