Mega Mini Precision Horizontal Machine

The key to success is thirty years of technological accumulation

Imported from Europe. Independent intellectual property rights. EU CE certification

Unique screw plasticization system + plunger injection system + injection accuracy can reach 0.01g

Mega Company has 30 years of experience in manufacturing micro injection molding equipment, accumulating rich application cases and a strong technical support team.

The birth of the micro injection molding machine is to produce small and micro plastic parts that require precise control of injection volume. By using the MegaTech series micro injection molding machine, customers can reduce equipment investment, lower labor costs, and reduce electricity consumption.

Advantages of Injection System

Screw plasticization + piston injection, injection accuracy can reach 0.01g

Mega micro injection equipment has back pressure and can produce thicker products

Injection and melting are synchronized, resulting in a short injection cycle (world-leading)

Quick Material Change

Changing materials is very convenient and saves materials due to our equipment.

It is screw plasticization, and the mixing color is very uniform, making color change easy.

Environmentally Friendly. Ultra-low energy consumption

The total rated power of the MEGA micro injection molding machine is only 3KW.

Our machine saves about 100,000 yuan in electricity costs every year;

Normal production consumes 1.5-2.5KW, compared to a 110-ton injection molding machine.

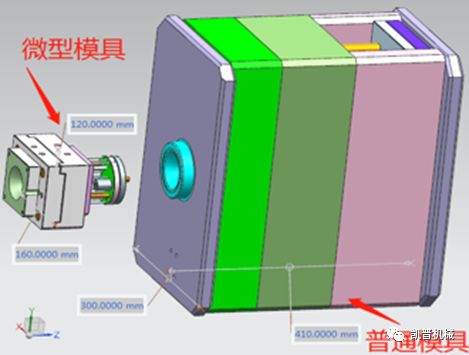

Cost-saving for Molds

Mega micro molds only have mold cores, no mold bases are needed, as the machine plate acts as the mold base.

The cost of making molds will be half that of traditional molds, shortening the mold production cycle by 2/3,

and saving space for storing molds.

Saving Gate Material

Mega micro molds only have mold cores, and the gate cross-section is small and very short,

the gate is generally only 1/3 to 1/5 the weight of traditional mold gates.

Small Footprint

The MEGA micro injection molding machine is tightly designed, with dimensions

1095*780*487mm, and a total weight of only 250kg.

It is a desktop injection molding machine, saving nearly 1/5 of the floor space.

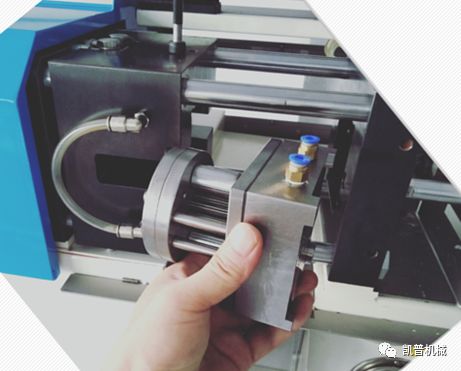

Flexible Mold Change

The fixed template of the injection molding machine adopts multiple bolt hole installations

and can be replaced within three minutes.

Wide Injection Range

The heating temperature is within the range of 450°, allowing for the injection of any engineering plastics,

and can also process non-plastic products such as powder metallurgy and ceramic metals.

——————-

About Kaipu:

Megatech Italian injection molding equipment Asian division

A one-stop provider from product design evaluation to injection molding production services

Global leader in micro injection molding equipment, horizontal/vertical/multi-color multi-material injection equipment

Liquid silicone gel injection machine, liquid silicone (LSR) injection machine

For more videos and materials, please long press the QR code below to follow our official WeChat account.