Click the blue text to follow us

In the field of chip design, Zhuhai Jihai Semiconductor, which has been in operation for less than five years, has become a rising force in the industry. This technology company under the Nasda Group recently launched the G32R501 series of embedded control chips, enabling industrial robots to perform “mechanical ballet” and making the battery management systems of new energy vehicles smarter.

To discuss the company’s core competencies, we must start with their technical foundation. The parent company, Nasda, has been involved in the field of encryption chips for over twenty years, passing on all its hardcore technology to Jihai. Last year, they launched the G32R501 chip, which has elevated real-time control performance to new heights, prompting even international giants to take notice.

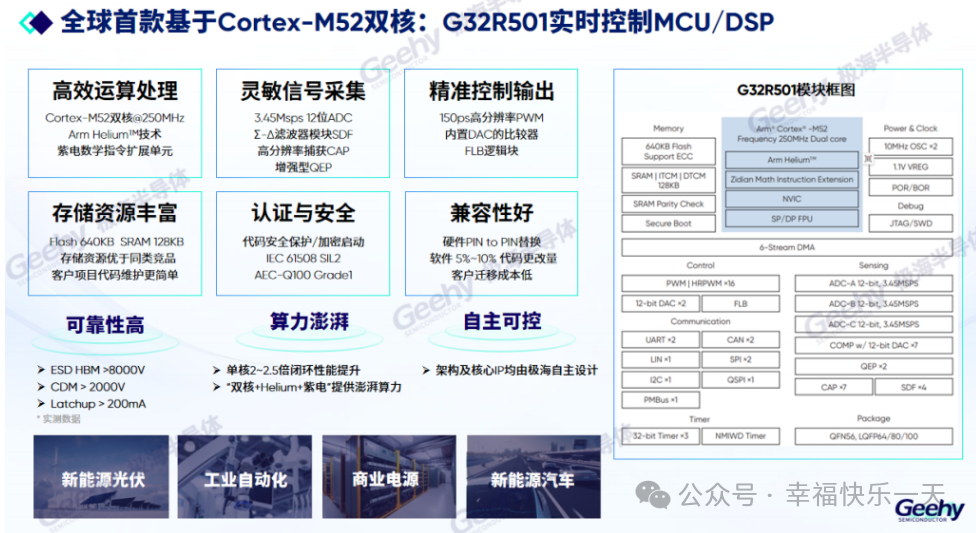

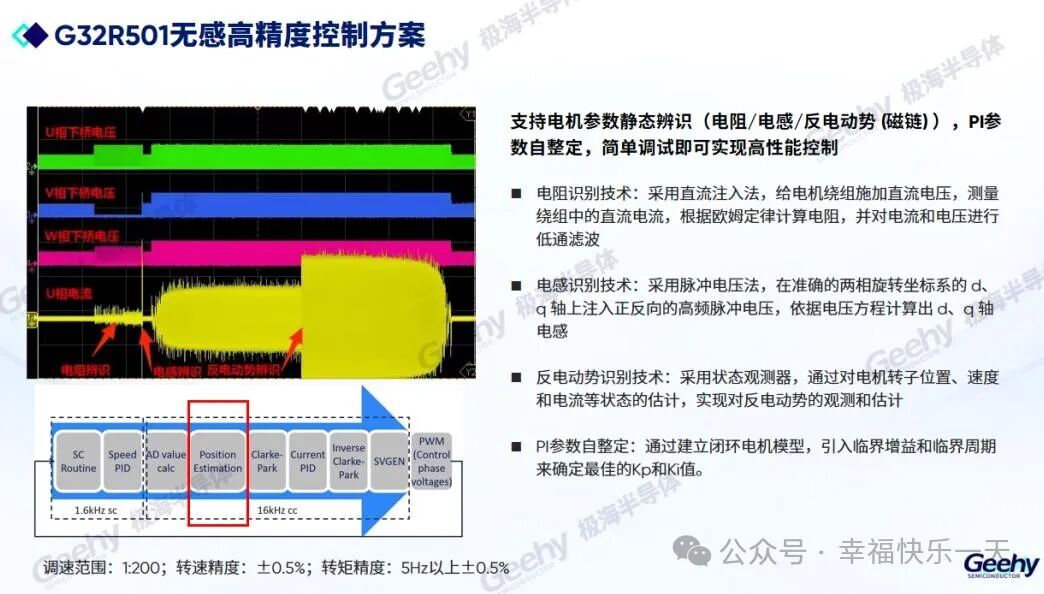

What capabilities does this chip possess? Let’s take industrial robots as an example. Previously, controlling robotic arms for precise movements required various auxiliary chips. Now, the G32R501 can handle motion trajectory planning and torque control all on its own, thanks to its dual-core brain hidden within the chip—two Arm Cortex-M52 processor cores that each have their own roles, one dedicated to real-time response and the other to data processing, working together more harmoniously than twins.

Even more impressive is the mathematical accelerator inside the chip called “Zidian.” It’s like having a super assistant dedicated to solving mathematical problems, capable of performing Fourier transforms and matrix operations at speeds more than three times faster than traditional methods. Engineers have tested this chip to control a six-axis robotic arm, reducing the path planning time from 2.3 milliseconds to 0.8 milliseconds, achieving precision that directly competes with high-end Swiss equipment.

In the field of new energy vehicles, this chip has also introduced new features. The biggest concern for battery management systems is thermal runaway, and the G32R501 can complete state monitoring of 128 battery cells within 0.1 seconds. Last year, a domestic electric vehicle brand conducted high-temperature tests, and the model equipped with this chip achieved a temperature difference control accuracy that was 42% better than competitors, leaving German suppliers astonished.

Safety performance is another strong suit of this chip. The built-in encryption module can secure core algorithms more tightly than a bank vault. Last year, a foreign company attempted reverse engineering and spent three months without finding a breakthrough. Now even military enterprises are approaching for collaboration, seeking to upgrade their drone control systems.

Speaking of development tools, Jihai’s collaboration with IAR is quite noteworthy. The development kit they created together allows engineers to configure chip functions as easily as building blocks. A startup team used this tool to compress the development cycle of a servo motor control system from six months to eight weeks, significantly speeding up product launch compared to competitors.

Currently, the global manufacturing industry is undergoing intelligent upgrades, and chips like this, which can withstand the high-temperature workshops of automotive manufacturers while also being suitable for precision medical equipment, have a significant market gap. It is reported that automation manufacturers in Southeast Asia are already lining up to place orders, and even traditional German companies that typically use European and American chips are sending representatives to Zhuhai for inspections.

However, what has shocked the industry the most is the cost-performance ratio of this chip. Similar performance imported chips sell for $30, while Jihai has managed to price it at $18. No wonder industry insiders joke that this is not just selling chips, but truly making technology accessible. It seems that in the field of intelligent equipment, domestic chips are set to take the lead.