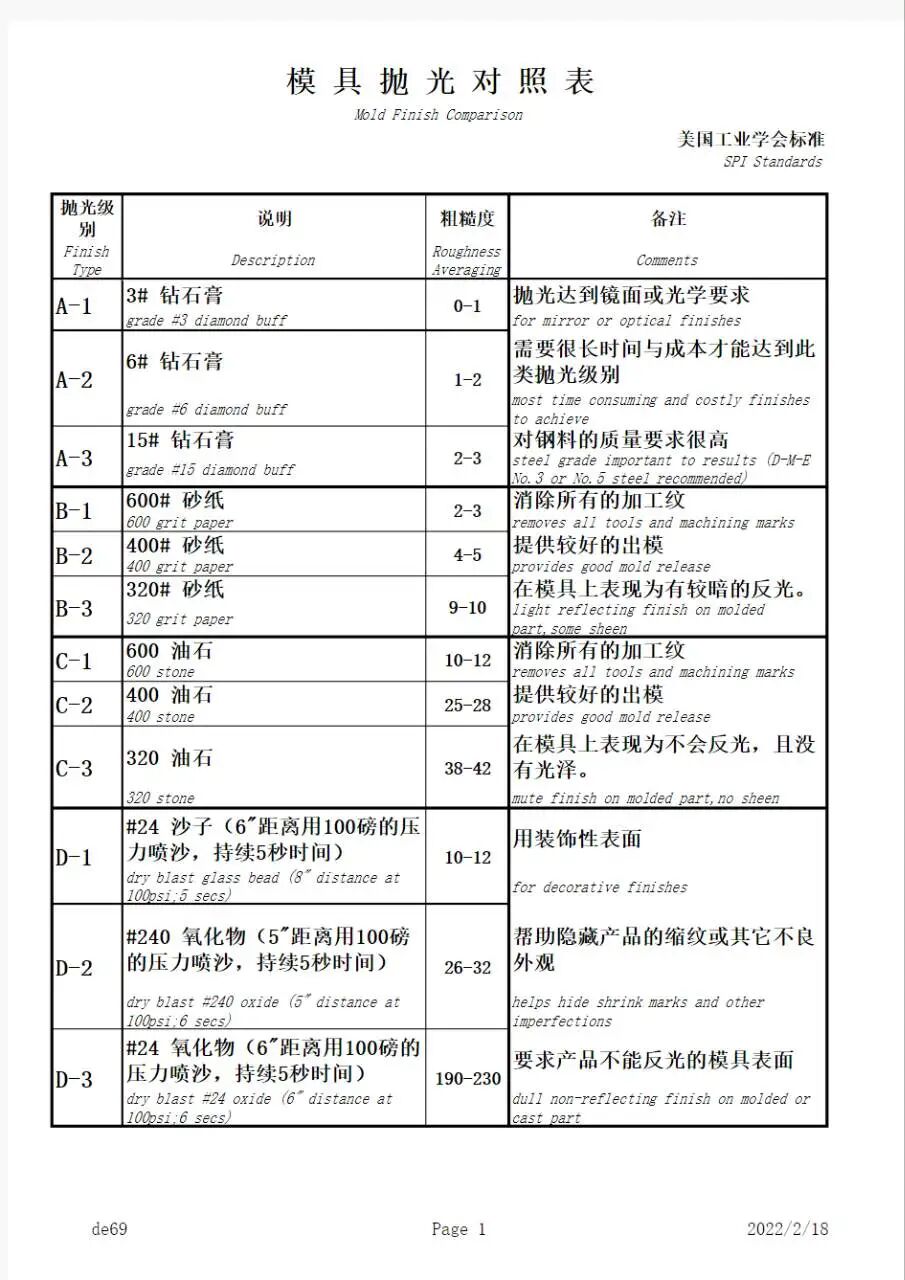

The following diagram shows the SPI standard mold polishing grade table, from which the polishing grades A~D in the mold industry originate. The A-grade claimed by 3D mold manufacturers also comes from here.

There are four columns:

~ The first column is the grade code

~ The second column is the abrasive, tool, and polishing process

~ The third column is the roughness, measured in Ra

~ The fourth column is the application scenario

Question: Why do polishing grades need to include abrasives and tools?

Answer: Because this standard assumes that mold polishing is performed on 100% dense materials or on materials with intrinsic defects smaller than the scratches made by the abrasives.

Question: What if the base material of the mold has defects?

Answer: In this case, abrasives cannot be used to correspond to the grade, because the inherent defects of the defective material cannot be polished away. When the size of the defects in the base material is smaller than the scratches caused by the abrasives, it can be used.

Question: For 3D printed molds, if they contain spherical defects with an average size of 5~8um, what is the highest roughness grade achievable?

Answer: Theoretically, it can reach Ra2.5~Ra4, corresponding to B1 or B2.

Question:How do the 3D manufacturers on the market claim A2 or even A1 polishing grades for printed molds?

Answer: Reason 1, weak grasp of theoretical knowledge about polishing grades. Reason 2, the probe method used for testing has a probe tip size that is too large. Reason 3: Early practitioners and some unprofessional companies boast due to ignorance, leading later entrants to make such claims (everyone must deeply understand this).

Question: Is there any evidence that the values measured by the probe method for 3D molds cannot be used?

Answer: The fourth column of the SPI standard states that A-grade can be used optically. However, the few micrometer defects on the surface of actual 3D printed molds are sufficient to have a fatal impact on optical applications. Moreover, SPI clearly states that “the quality requirements for steel are very high,” and the defect sizes of 3D molds do not meet the standard definitions. A simpler explanation: The diamond paste used for A-grade polishing can completely get stuck in the defect pits of 3D molds and cannot come out.