Competition Distributing LLC, a benchmark enterprise in the global antique motorcycle parts manufacturing and supply sector, has long been dedicated to providing professional restoration solutions for legendary brands such as Harley-Davidson and Indian Motorcycle. Headquartered in Pennsylvania, USA, the company leverages its deep industry experience to offer rare original parts and precision aftermarket components to collectors, top restorers, and museum institutions, safeguarding a motorcycle cultural heritage that spans three centuries.

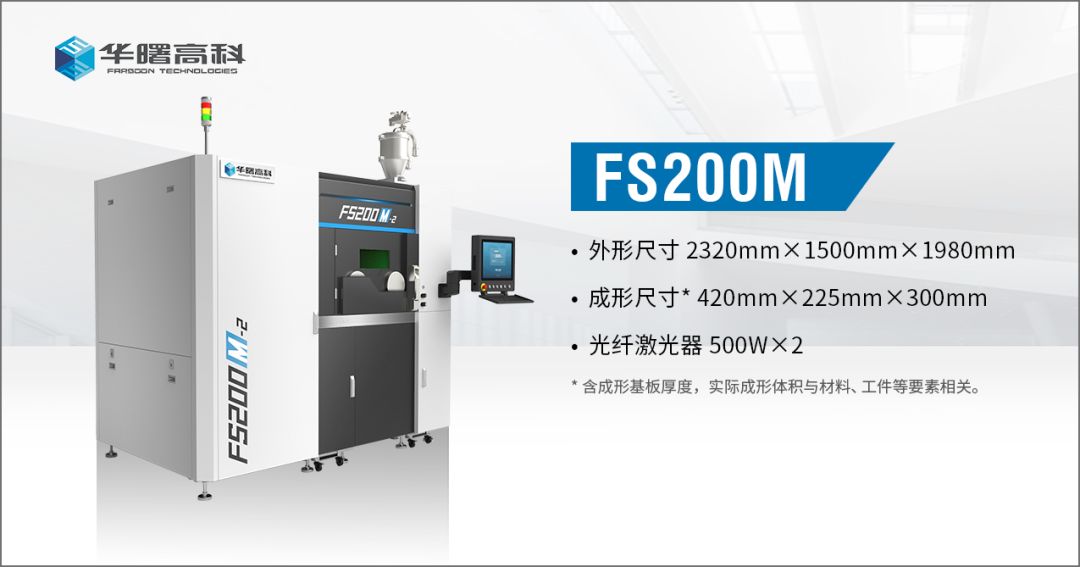

Faced with the crisis of parts extinction for antique motorcycles dating back to the 1930s and earlier—many of which are century-old treasures displayed in museums—founders Sean and Kevin innovatively introduced Huashu High-Tech’s metal additive manufacturing solution, the FS200M-2, breaking through traditional restoration bottlenecks and achieving precise replication of irreplaceable components, providing technical assurance for the historical authenticity certification of antique motorcycles.

“These parts not only serve museum collections, but we also hope that ordinary enthusiasts can manufacture, ride, and experience early motorcycles just like they did 100 years ago,” said Sean, the Operations Director of Competition Distributing. By integrating cutting-edge additive manufacturing technology with vintage engineering, Competition Distributing not only revitalizes history but also allows classic motorcycle culture to continue thriving within modern manufacturing systems.

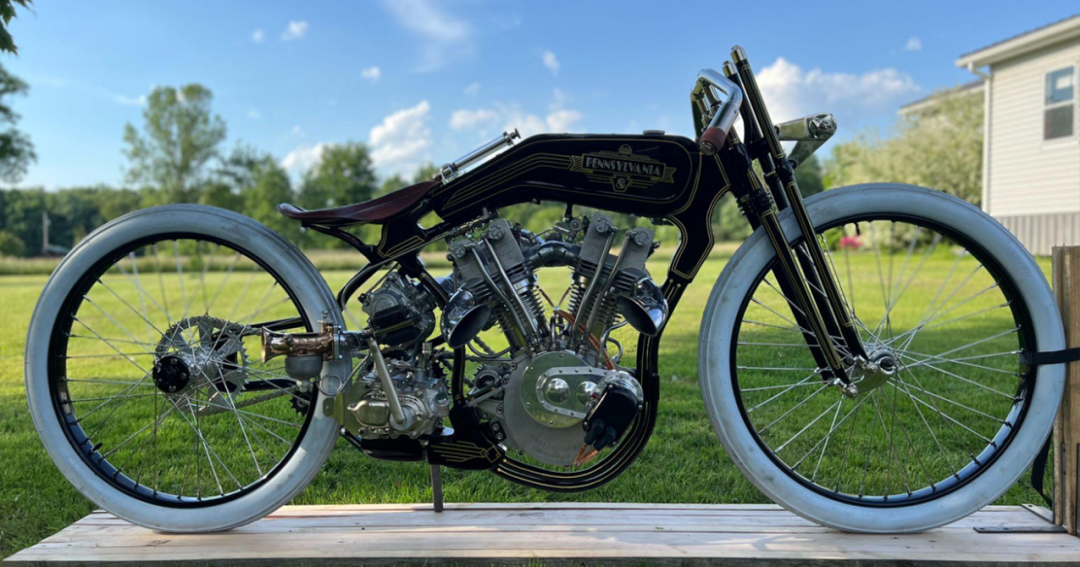

Metal 3D printed components installed on “The Pennsylvania 8” custom motorcycle. Image source: Sean Jackson

From April 8-10, during the Rapid+TCT 2025 exhibition in Detroit, Huashu North America will showcase the century-old antique motorcycle restored by Competition Distributing at booth #1701. We welcome you to experience how metal additive manufacturing breathes new life into classics and witness the stunning inheritance of a century-old motorcycle culture empowered by technology!

Recently, Alex Gao, a marketing specialist at Huashu High-Tech North America, interviewed Sean, the Operations Director of Competition Distributing, to discuss how the company has transformed its business through additive manufacturing technology.

Exploring the Transition to Metal 3D Printing

Alex: Sean, thank you for accepting our interview. Competition Distributing has always been a significant player in the motorcycle parts replication field. What prompted your company to adopt metal powder bed fusion (PBF) technology?

Sean: Thank you, Alex, I’m glad to participate in this discussion! My team partner Kevin and I previously had experience with polymer additive manufacturing and understood the potential of 3D printing.

Initially, we completely outsourced metal 3D printing, primarily using SLM technology. However, we soon realized that compared to traditional mold casting, which requires months of processing time, SLM technology offers higher efficiency and greater flexibility. This comparison prompted us to decide to purchase our own metal 3D printer, and that was when we decided to reach out to Huashu North America.

Introducing Huashu High-Tech FS200M-2 to Expand Capacity

Alex: I’m glad to collaborate with you! How has the FS200M-2 been performing since its implementation?

Sean: Since we introduced the FS200M-2 dual-laser metal additive manufacturing equipment in October 2024, its performance has far exceeded our expectations. We can now deliver end parts within days, whereas previously, relying on traditional processes took months, and customers are particularly satisfied with the accuracy and surface quality!

This equipment has had a profound impact on our business, especially in the high-end collector custom projects. It has enabled us to achieve technological breakthroughs that were previously unattainable.

Thanks to its outstanding reliability, we can operate this equipment almost around the clock, maintaining stable and consistent production, which is the core foundation supporting our future strategic expansion.

1928 Rudge Cycle Co. antique motorcycle cylinder head, printed with AlSi10Mg aluminum alloy using the FS200M-2. Image source: Sean Jackson

Success Case: Restoring Irreplaceable Components

Alex: We are glad to hear this news! Has the FS200M-2 had a significant impact on any specific projects?

Sean: Absolutely. One of the biggest challenges in the vintage motorcycle restoration field is sourcing frame components, especially castings—these parts are not only rare but almost extinct in the market.

Now, with the metal 3D printing capabilities of the FS200M-2, we can scan original components (some over a century old) and replicate them with ultra-high precision, even preserving the surface imperfections and casting textures of the original castings. This extreme restoration of historical details is exactly what collectors dream of and has completely revolutionized our restoration process.

Material Selection and Future Plans

Alex: What materials are primarily used with the FS200M-2 equipment currently?

Sean: Currently, we mainly use 316L stainless steel, which is suitable for most of our frame components. We also plan to expand to aluminum alloys, 17-4PH stainless steel, and titanium alloys in future projects.

In the long term, as our production scale continues to grow, we hope to dedicate specific materials for fixed equipment to ensure higher production efficiency and consistency.

Technical Support and Learning Curve

Alex: How has your experience been with Huashu’s localized technical support?

Sean: It has been really solid. Our team consists of engineers and mechanics, so communication with the Huashu North America technical team has been very efficient.

The biggest challenge has been the learning curve—we had never operated such large-scale metal additive manufacturing equipment before. We spent about three to four weeks continuously printing before we finally achieved stable production. Since our parts are based on vintage casting designs (asymmetric and not optimized for additive manufacturing), the support layout and process parameters required repeated refinement, but once we overcame the challenges, the consistency of the finished product quality is outstanding.

Special thanks to Huashu North America team members Drew and Ty, who are always quick to resolve technical issues. I highly recommend your team.

Huashu Software: An Innovator in Transformation

Alex: Is there anything particularly special about the equipment’s usage?

Sean: The functionality of Huashu’s software has been a pleasant surprise. I can now remotely monitor and control the printing process directly from my phone, adjust powder parameters in real-time, and even delete individual parts in real-time without canceling the entire print job. This flexibility has saved us a lot of time and material costs.

Welcome to Rapid+TCT 2025!

Alex: Thank you, Sean, for sharing your journey with us! We are also honored to announce that during the Detroit Rapid+TCT 2025 exhibition, one of the antique motorcycles you restored will be displayed at Huashu North America booth #1701!

Sean: It is our honor! We are excited to showcase this piece of history to more audiences. The Competition Distributing team will also be on-site at the Huashu North America booth to answer your questions—looking forward to seeing you there!

About Competition Distributing

Since 1968, Competition Distributing LLC has been a leader in antique motorcycle parts and accessories, with over 40 years of professional experience, focusing on producing high-quality aftermarket Harley-Davidson antique motorcycle parts, some of which date back to 1910. The company’s mission is to provide first-class original and aftermarket antique motorcycle parts to collectors and restorers worldwide through professional procurement and advanced manufacturing processes. The company has a team of experienced engineers and mechanics to ensure antique motorcycles are always ready to hit the road, preserving the cultural heritage of antique motorcycles for enthusiasts around the world.

Welcome to Share

Welcome to join the PhD and Master exchange groupQ group:248112776

Further Reading:

1. A 4000-word overview: Technical challenges of manufacturing heat exchangers with 3D printing technology

2. Tuo Bamboo H2D sales have exceeded 2000 units, creating over 24 million in sales

3. 3D printing and shoe industry application innovation forum, AVIC Mite empowers digital innovation in shoe mold manufacturing

4. Weilai’s first-quarter revenue increased by 125% year-on-year! Completing the localization deployment of DeepSeek-R1