In January of this year, most regions in China experienced severe cold weather. Some jokingly said they could run benchmarks on their phones to keep warm, reflecting a deeply rooted issue in people’s minds regarding phone heat generation. As the core of the mobile phone, the CPU largely represents the phone’s performance. From the initial 1GHz frequency, to single-core, dual-core, quad-core, octa-core (hexa-core), and now the newly launched deca-core processors, many CPU manufacturers have adopted the “simple and crude” method of increasing the number of cores to enhance performance. However, the increase in CPU performance also brings some issues, the most significant of which are power consumption and heat generation.

The role of smartphones in our lives is becoming increasingly significant, and users’ performance requirements are naturally rising. However, the biggest difference between smartphones and traditional PCs is their mobile usage habits; it is not feasible to be connected to a power source at all times (though there are portable chargers). Thus, how to extend the battery life of smartphones while meeting the minimum usage requirements has become a focal point for both the industry and consumers. How can we address the issues of CPU power consumption and heat generation? CPU manufacturers are continuously striving for solutions. Currently, there are three main methods to reduce mobile CPU power consumption and heat generation, which this article will introduce and analyze one by one.

Intelligent Frequency Technology for CPUs

Currently, the official frequencies of mobile phone CPUs range from 1.0GHz to 2.5GHz, and in the future, the main frequency will continue to rise to extract more performance from the CPU. However, under the premise of other factors remaining unchanged, higher frequencies inevitably lead to higher power consumption. Thus, one simple and crude method to reduce mobile power consumption is to lower the CPU’s main frequency.

For example, a mobile CPU can reach a maximum frequency of 2.5GHz, but in reality, this CPU operates at 2.5GHz only in very limited scenarios and durations, such as during benchmarking or running large applications or games. Furthermore, the time this performance and power peak can be maintained is also very limited. For most of the time, this CPU may only run at lower frequencies, such as 2.0, 1.5, or even 1.0GHz. These usage scenarios require much lower performance, and through internal control programs, the CPU’s main frequency can be lowered to extend the phone’s battery life while ensuring user experience.

More Advanced Manufacturing Processes

Compared to frequency reduction, improving manufacturing processes yields much more in terms of performance and power consumption. How significant can manufacturing processes be? Let’s analyze two examples. First, from Apple’s A7 processor in the iPhone 5s, to the A8 processor in the iPhone 6, and the A9 processor in the iPhone 6s, their performance has continuously improved, yet the batteries for these three generations of iPhones have not only failed to increase but have actually decreased, while the iPhone’s battery life has remained at the same level (which is not great).

Why can such a balance between performance and power consumption be achieved? One of Apple’s methods is through continuous improvement of manufacturing processes. The A7 uses a 28nm process, the A8 uses a 20nm process, and the A9 has further reached a precision of 16/14nm.

Regarding the chip issue that caused quite a stir last year with the iPhone 6s and 6s Plus, why does TSMC’s 16nm version have better power consumption than the 14nm version? Please refer to our previous analysis article “Why Does the iPhone 6s Have Two Versions of CPU?” http://mobile.pconline.com.cn/703/7032736.html

The Relationship Between Manufacturing Processes and Power Consumption, Performance

Essentially, a CPU (processor) is a circuit stacked from many layers made of different materials, containing tiny components such as transistors, resistors, and capacitors. The smaller their spacing, the more components can be arranged on the chip, and the capacitance between transistors will also be lower, thus increasing their switching frequency. Since the dynamic power consumption of transistors when switching electronic signals is proportional to capacitance, they can achieve faster speeds while being more energy-efficient.

Of course, people may also think that aside from the improvement in manufacturing processes, Apple’s A7, A8, and A9 also have significant differences in CPU design. Perhaps the above examples cannot better reflect the impact of manufacturing processes. The second example is last year’s Qualcomm Snapdragon 810 and Samsung Exynos 7420, one using a 20nm manufacturing process and the other a 14nm process. Based on the corresponding terminal mobile products from last year, the 14nm Exynos 7420 has significantly optimized performance and power consumption.

Comparison of Four Mainstream Processors in 2016

This year, whether it’s Huawei’s Kirin 950, Qualcomm’s Snapdragon 820, or Samsung’s Exynos 8890, they all adopted the 16/14nm manufacturing process. In the context of manufacturing processes being at a similar level, how can performance be improved and power consumption reduced? This will be discussed in the following content.

14nm vs. 16nm

The Kirin 950 uses TSMC’s 16nm FinFET Plus process, while the Snapdragon 820 and Exynos 8890 use Samsung’s 14nm FinFET process. Since there are currently no measured data, we can only boldly speculate that these two manufacturing processes are at the same level, providing greater room for performance and power consumption for the CPU.

About Manufacturing Processes

As mentioned above regarding Apple’s iPhone processors, improvements in manufacturing processes require support from upstream foundries. Transitioning from 28nm to 20nm, and then to 14/16nm requires long periods and substantial R&D costs, involving material science and other technological fields. The room for improvement after 14/16nm will become increasingly limited, and the difficulty will gradually increase.

Manufacturing processes are still a relatively tight resource for the entire chip industry. Whether it’s Apple, Qualcomm, or Huawei, they actually look for Samsung and TSMC for foundry production. However, the production capacity of Samsung and TSMC’s 14nm and 16nm production lines is also limited, serving only the major customers mentioned earlier, and only producing the most advanced flagship chips. For more information on chip processes, you can check our previous article “How Much Do You Know About Mobile SoC Processes?”

New Independent Architectures

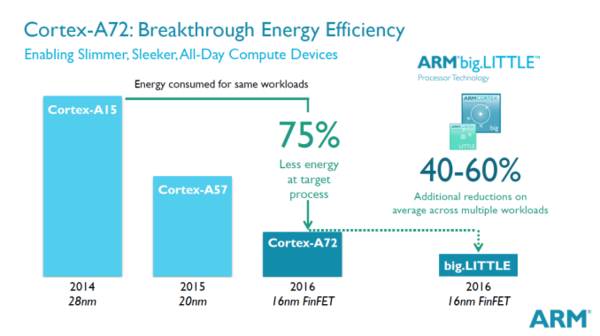

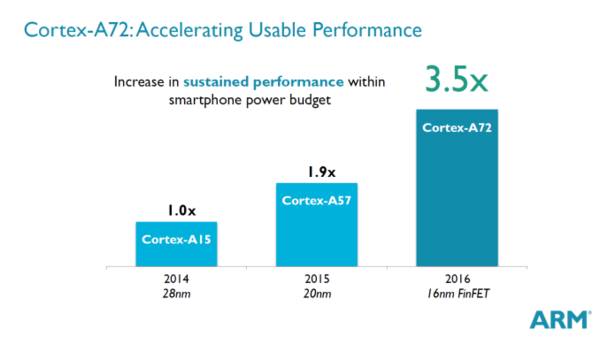

CPU architectures can be simply divided into ARM architectures and independent architectures. First, let’s introduce and analyze the ARM architecture. Currently, the most heard are Cortex-A53, Cortex-A57, and Cortex-A72 (referred to as A53, A57, and A72 respectively). They are all 64-bit architectures launched by ARM. The former A53 is a relatively low-performance, low-power architecture (commonly known as a little core), while the latter two are high-performance architectures (commonly known as big cores). A57 accompanies high power consumption with its high performance, while A72 is the second generation of 64-bit architecture, which improves performance and has the biggest advantage of better power consumption. To pursue a better combination of performance and power consumption, mobile CPU often adopts a big.LITTLE dual-core architecture, which combines little cores with big cores.

For example, the Snapdragon 615 consists of eight cores, four of which are 1.0GHz A53, and the other four are 1.7GHz A53; similarly, the Snapdragon 810 consists of four 1.5GHz A53 and four 2.0GHz A57 cores. As mentioned earlier regarding frequency reduction, when users are only sending messages or browsing Weibo, only two or three of the four A53 cores need to be activated, which requires very low power consumption. However, when users are running benchmarks or playing games, all eight big and little cores may be activated, leading to peak performance but also significantly high power consumption, which can drastically reduce the phone’s battery life.

A72 Architecture Significantly Reduces Power Consumption (Based on 16nm Process)

A72 Architecture Significantly Improves Performance Compared to A15 and A57 (Based on 16nm Process)

ARM indicates that A72 is optimized based on A57. From architectural diagrams and specifications, A72 and A57 are not fundamentally different; the first and second-level cache capacities are the same, with only minor adjustments made, such as removing the encryption extension feature of the NEON SIMD engine, while the bus interface has been expanded to 128bit. Therefore, we speculate that the performance improvement of A72 may come from micro-architecture optimization. However, ARM also states that A72’s performance is 3.5 times that of the A15 processor, with a 75% reduction in power consumption under the same workload, and with the big.LITTLE architecture, power consumption can be reduced by 40%-60%.

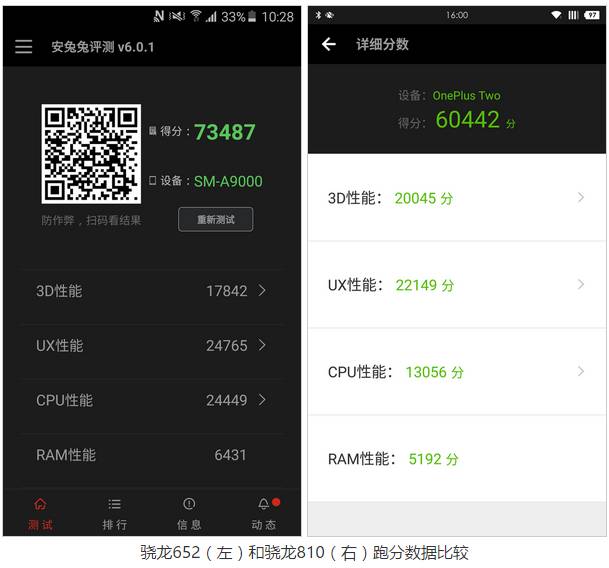

Above comparisons are mostly based on official data. Here we make a simple comparison between Snapdragon 810 and Snapdragon 652. The former uses a 20nm manufacturing process, consisting of four 1.5GHz A53 and four 2.0GHz A57 cores, while the latter uses a 28nm manufacturing process, consisting of four 1.4GHz A53 and four 1.8GHz A72 cores. Based on benchmark data and actual usage, the mid-range Snapdragon 652 has already approached the single-core performance scores of the previous flagship Snapdragon 810, and the heat issues have also been well addressed, making it more suitable for mobile device usage requirements.

Having discussed ARM’s standard architecture, let’s now talk about the “rich and colorful” independent architectures.

Apple

Apple initially collaborated with Samsung to launch customized processors, but to achieve better performance, Apple gradually moved towards independently developing processors. Apple’s A-series processors are based on the ARM instruction set, but Apple has made extensive modifications and optimizations, not only to better match its iOS system but also to achieve industry-leading levels in performance and power consumption.

While Android phones have evolved from quad-core and octa-core to the upcoming deca-core architecture this year, Apple stubbornly continues to use its “ancestral” dual-core architecture. However, Apple’s dual-core architecture has also undergone changes. The A7 was the first to introduce a 64-bit processor into mobile products, and the subsequent A8 and A9 processors not only improved in manufacturing processes to achieve better energy efficiency but also benefited from new core architectures, greatly enhancing their performance. Even in the face of competitors’ quad-core, octa-core, and deca-core products, Apple remains undeterred. Apple CEO Tim Cook even claimed that the iPad Pro equipped with the A9 processor (enhanced version) has surpassed many traditional PC products in performance.

Qualcomm and MTK

Apple’s A-series processors and iOS form a closed hardware and software ecosystem, but for most phone manufacturers and users, the hardware development of the Android platform is what truly matters. Currently, Qualcomm and MTK (MediaTek) are the main processor suppliers for the Android platform (in the public domain), while Samsung and Huawei also have their own processors, but they sell only a small amount or not at all, so they will not be discussed in this article.

The Vivo Xplay5 flagship model uses the Snapdragon 820 processor

From Scorpion, Krait to this year’s Kryo architecture, Qualcomm has been continuously working on developing its own core architecture. Although last year Qualcomm had to release ARM standard Snapdragon 810/808 to meet market demand for 64-bit processors, this year’s Snapdragon 820 adopts the latest Kryo 64-bit independent architecture. The four-core processor outperforms last year’s flagship Snapdragon 810, and it is also confident in the face of competitors’ octa-core or deca-core products, with power consumption performance better than Snapdragon 810, thus better meeting the performance and power consumption requirements of flagship mobile devices. Currently, the Chinese versions of Samsung S7/S7 edge, LeEco Max Pro, Vivo Xplay5 flagship model, and Xiaomi 5 have all adopted the Snapdragon 820 processor, and more mid-range and high-end products will follow suit.

Snapdragon 652

Currently, Qualcomm plans to use the Kryo architecture for mid-range and high-end products, while lower-tier products will still adopt ARM standard architecture solutions, such as this year’s main Snapdragon 652/650 products. As mentioned earlier, thanks to the benefits of A72 in power consumption, the Snapdragon 652 has resolved the power consumption issue while also achieving single-core performance scores close to last year’s Snapdragon 810.

Helio X20

Recently, MTK finally released its latest Helio X20 processor, which adopts a Tri-Cluster deca-core architecture, consisting of two A72 cores with a frequency of 2.5GHz, four A53 cores with a frequency of 2.0GHz, and four A53 cores with a frequency of 1.4GHz, designed for handling various high, medium, and light load tasks in mobile devices. Helio X20 is manufactured based on a 20nm process (TSMC foundry) and also supports MediaTek’s CorePilot heterogeneous computing technology, which can allocate CPU and GPU workloads, managing both processor performance and power consumption, achieving better performance with lower heat generation. Based on last year’s collaboration and recent news, manufacturers such as Meizu, LeEco, and 360 Mobile are expected to be among the first users of the Helio X20 processor, with more products featuring Helio X20 expected to emerge in the second quarter of this year.

Conclusion:

Although the power consumption issue of mobile processors has been significantly alleviated, in the absence of breakthrough developments in battery technology and with increasing mobile usage demands, how can mobile phones be more energy-efficient and achieve longer battery life remains a common issue for the industry. While pursuing performance, the author hopes that both manufacturers and users will shift their focus from performance to power consumption and battery life, or from pure performance benchmarks to user experience.