Dedicated to the research and development of digital twin technology

Benefiting humanity through solutions and engineering applications

Source: Digital Enterprises

Author: Peng Yu

Abstract

The success of smart manufacturing and industrial digital transformation plans requires consideration of many factors. The most critical is to solve the acquisition of the correct data, convert it, and transmit it to the right place for further analysis and decision-making.

In the digital transformation of industry, fully releasing data is an inevitable path. To fully release data, three key issues must first be addressed, namely:

-

Creating large-scale and wide-ranging device connections and various data source connections

-

Acquiring data and determining the storage space for this data

-

Performing data conversion and processing, and sending it to the systems and devices that need this information for analysis, decision-making, and execution

This article aims to explore how to address these three key issues.

The scope of digital transformation planning far exceeds that of the original automation control systems and enterprise management systems, thus becoming larger and more complex, requiring efficient, high-performance, and inclusive communication technologies and system architectures.

Methods for connecting and acquiring data are divided into two main categories:

1) Control specific networks and protocols,

2) Open/standard-based protocols.

The former consists of standard and proprietary field buses and industrial Ethernet, while the latter includes two prevailing trends involving OPC UA and MQTT. Open protocols MQTT + Sparkplug and OPC UA + OPC supporting specifications and information models are important options for addressing industrial IoT IIoT standardization and interoperability.

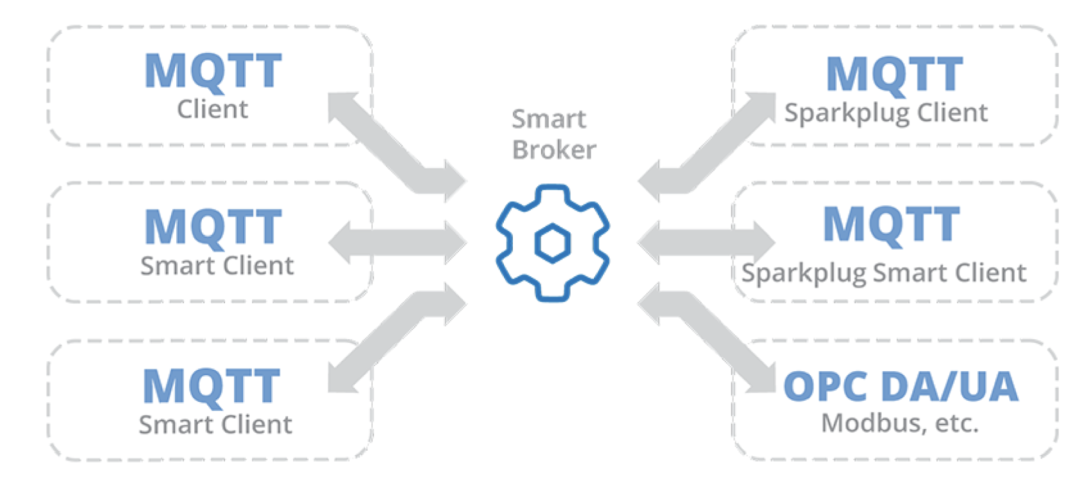

MQTT is a lightweight communication transport protocol suitable for bandwidth-limited networks and applications with multiple clients and devices, where these clients and devices share data in a many-to-many manner (Figure 1). It enables clients to publish and subscribe to data in cloud or internally hosted brokers, which manage and route data to subscribed clients. MQTT itself does not define the data format in the packet (i.e., the payload), which can lead to interoperability issues and vendor lock-in risks due to vendors defining the payload format.

Users of MQTT and Sparkplug need to consider using smart MQTT clients and brokers, rather than just moving data. Smart clients or brokers will handle multiple payload formats on the same connection, able to automatically extract MQTT topic data into tags for standard use like OPC, and manage the propagation of data connection quality status. If control decisions depend on MQTT data, then smart clients or brokers must address the management of lost and out-of-order messages, ensuring that message order is correctly preserved, handling failed write operations, and storing and forwarding addresses during network downtime.

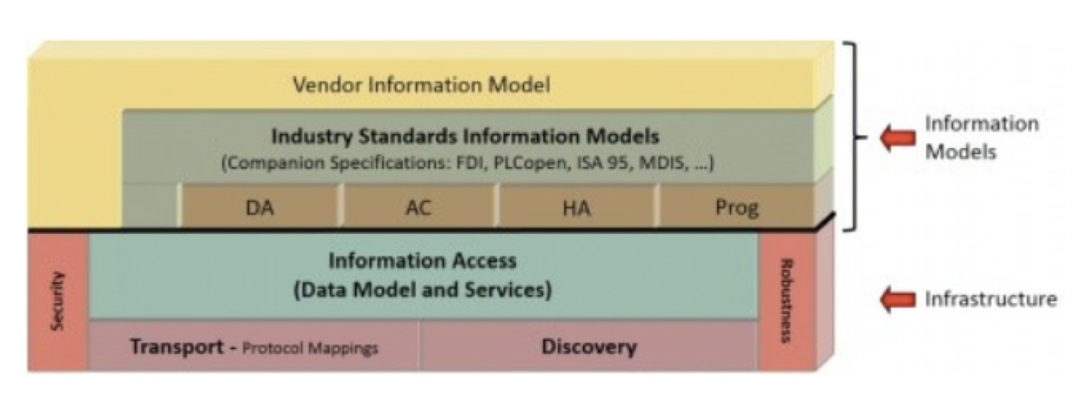

OPC UA (Open Platform Communications Unified Architecture) standard is another powerful tool that provides a standardized framework for data exchange and communication between different industrial systems, devices, and applications. As the evolution of the classic OPC standard, the OPC UA standard defines secure integration methods for exchanging extensive industrial data, as well as standardized information models typically used for data exchange in specific vertical industries, which have well-defined namespaces.

In addition to specifying basic information models (DA, Data Access; AC, Alarms & Conditions; HA, Historical Access, etc.), the OPC UA specification is equipped with industrial standard information models described by supporting information models (such as PLCopen, ISA 95, AutomationML, etc.). Figure 2 illustrates the architecture of the OPC UA information model.

The OPC UA supporting specifications provide XML definition files for available industry or general technology information models published by the OPC Foundation, to quickly authorize client and server applications to share industry-specific data within the model. Generally speaking, OPC UA contains syntax standards but is not responsible for defining semantics; the expression of its semantics is conveyed through supporting industry information models or proprietary technology supporting information models and their respective specifications. Therefore, in this sense, OPC UA merely conveys semantics rather than defining them.

Experienced users and integrators can also define and publish their own supporting information models based on their business needs to facilitate the exchange of factory data with supply chains or other partners. This data includes not only raw data but also historical and event data, metadata, and detailed information about data sources, data quality, and relationships between data points. OPC UA Pub/Sub (Publish/Subscribe) is an extension of the OPC UA protocol for applications requiring many-to-many communication, providing efficient transport for all types of data, including raw or formatted data within the OPC UA information model (regardless of whether from supporting specifications or user-defined). OPC UA Pub/Sub can also be used over MQTT, allowing users to leverage the high standardization of OPC UA supporting specifications and information models, along with the flexibility and simplicity of MQTT.

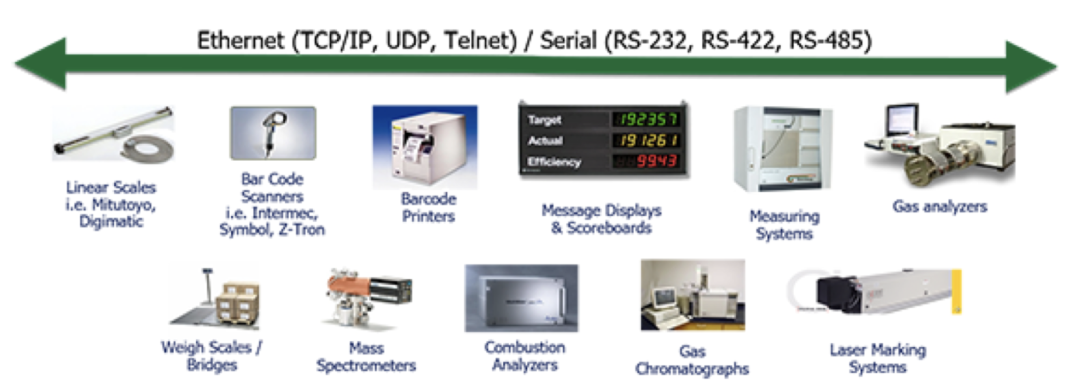

In any implementation, there will be instances where MQTT or OPC UA systems and the devices to be connected are not implemented in any form, thus requiring device replacement or integration software, or providing solutions for connecting and integrating standard PLC and control protocols, traditional devices, and non-standard protocol devices (see Figure 3). Existing commercial industrial software connects any device that only has serial or Ethernet interfaces by creating a visual configuration interface that complies with MQTT and OPC UA standards, and utilizes the documented communication protocols of OPC UA and MQTT. Such solutions enable numerous serial, USB, and Ethernet-connected devices to participate in data exchange of MQTT and OPC UA without the need to use open/standard protocols and without writing any custom code.

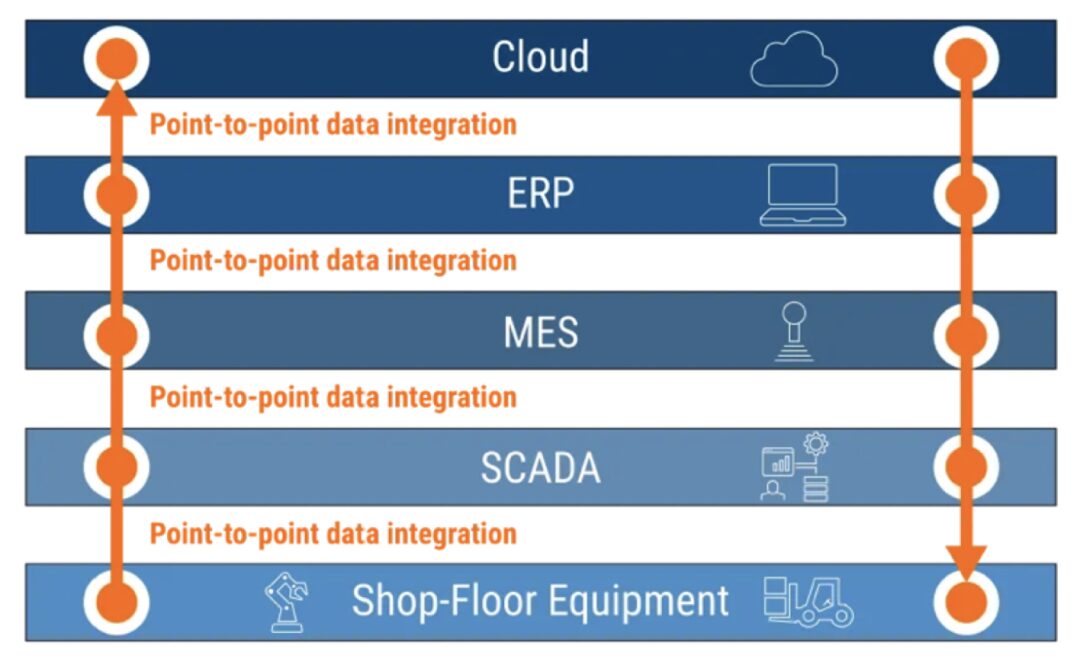

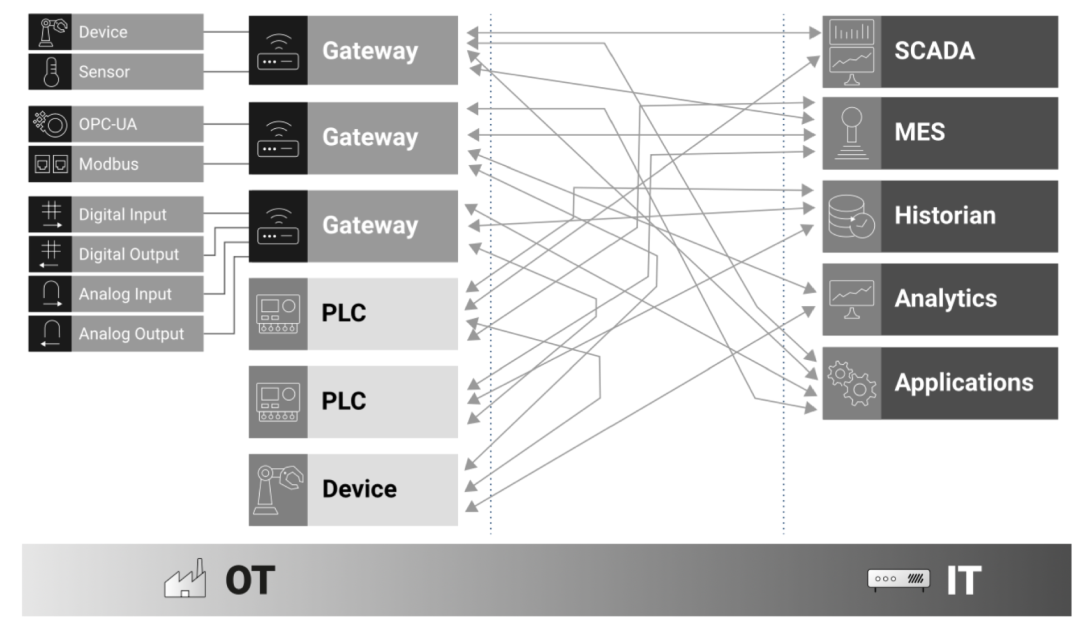

The vast majority of existing industrial information systems modeling adopts a traditional pyramid network and system architecture structure (as shown in Figure 4), based on functional modeling standards IEC 62264 /ISA 95 used to define interfaces between control functions and other enterprise functions. This architecture is characterized by describing components located at the bottom (factory level) and components at the top (enterprise/cloud level) using a technical stack. In this stack, each layer is interconnected and only communicates with the layer directly above or below it. Therefore, data is transmitted through point-to-point connections, with each transmission moving one layer up or down. This client-server architecture based on layers is one way to implement the IEC 62264 /ISA 95 standards. However, IEC 62264 /ISA 95 does not specify how to implement pyramid network and system architectures because it is purely a functional modeling standard, not an interconnection network standard.

Clearly, this architectural approach is unsuitable for building smart manufacturing systems, partly because such systems are difficult to manage, the coupling of data transmission is too tight, and more importantly, such systems are not scalable. A perceptive observer can clearly see its drawbacks in Figure 5.

Figure 5 Traditional architecture is difficult to manage, tightly coupled, and not scalable

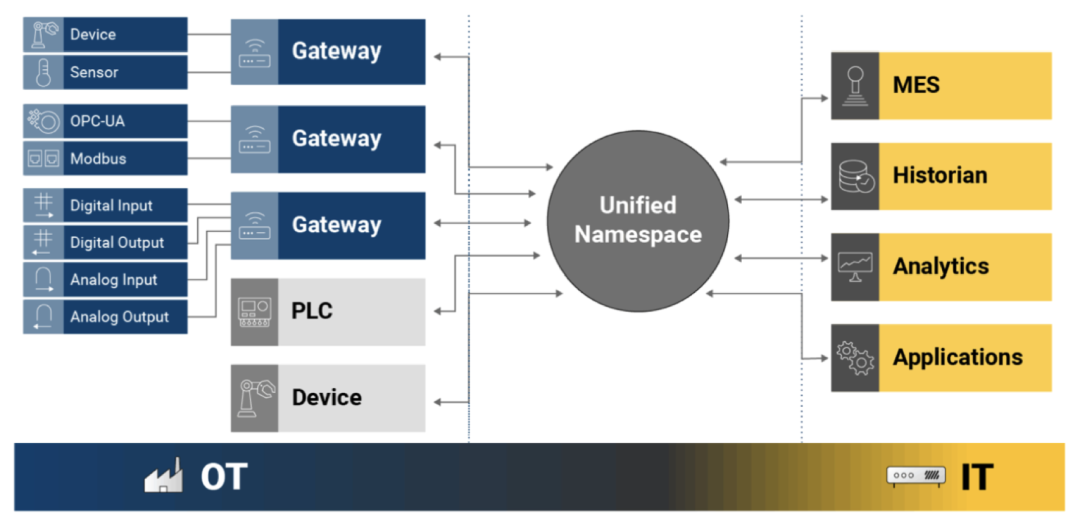

A more suitable smart manufacturing architecture should be as shown in Figure 6, where network participants do not directly touch each other. They publish their information to a central information repository, that is, a unified namespace. Other participants can then extract useful information from the unified namespace as needed. Since all direct communication is completely removed, it becomes easy to integrate control systems with IT systems without needing to understand each other’s implementation details. In fact, in a unified namespace architecture, if a device from vendor A is replaced by a device from vendor B, as long as the new device publishes its information to the same topic namespace as the old device, other network participants may not even be aware of this change. Using a unified namespace also allows smart manufacturing systems to be scaled on demand, which is another obvious advantage.

The earliest UNS project was constructed in 2005 by Walker Reynolds, the most important advocate of UNS. This project was implemented in a salt mine, using Dynamic Data Exchange (DDE) with Excel spreadsheets. In the following year, this project adapted MQTT technology.

From an automation perspective, UNS is a universal naming convention that organizes according to attributes such as the location, function, and type of devices, data points, and services. Furthermore, UNS is not just a naming convention but also an architecture that meets the following requirements:

-

UNS is a semantic hierarchy of business data and events.

-

UNS is a hub that connects all smart devices and IT infrastructure.

-

UNS is the single source of truth for all data and information in the business.

-

UNS is the foundation for digital transformation.

-

UNS is where the current state of the business resides, supporting real-time snapshots of the business.

In summary, UNS is an ontology communication layer that connects all other parts of IIoT. It provides a shared data hub that supports communication and collaboration between different systems and stakeholders, regardless of their underlying technology or vendor. This shared data hub can improve the interoperability, scalability, and flexibility of industrial IoT systems, reduce integration costs, and accelerate time to market or engineering.

Essentially, a unified namespace is a middleware solution that allows data to be collected from various industrial systems, adding a semantic context to it, and transforming it into a format that other systems can understand. One of the ways to implement a unified namespace is to use a Sparkplug-based network architecture. It turns out that the unified namespace architecture and IEC 62264 /ISA 95 are actually complementary. We can completely design smart manufacturing systems based on a unified namespace architecture and then use IEC 62264 /ISA 95 standards to model the data objects pushed to the unified namespace. This way, we can organize the components of the manufacturing system in an innovative and modern way while perfectly combining a proven and tested functional modeling standard for enterprise information integration that is widely used globally.

This leads us to conclude that while the data architecture based on IEC 62264 /ISA 95 standards played a significant role since the mid-1990s, blindly using it as the foundation for digital transformation strategies today poses significant risks, leading to many digital transformation efforts ending in failure.

The creation and implementation of the unified namespace (UNS) concept is a positive trend that supports effective information exchange, thereby supporting real-time decision-making. Utilizing UNS helps break down information silos, allowing enterprises to collect and analyze data from a wide range of sources, thus providing a more complete operational picture. UNS is effective in distributed environments across all applications, not just in one place. Tools that feed information into the UNS should meet standardized requirements. Technologies such as OPC UA, UA information model, UA Pub/Sub, MQTT, and MQTT Sparkplug, and OPC UA over MQTT all meet these requirements, while HTTP and Modbus Plus can also be used for UNS. Utilizing these technologies makes it possible for data to enter the UNS. Among these tools, MQTT Sparkplug uses a lightweight messaging protocol, making it very suitable for low-bandwidth or unreliable networks. Meanwhile, OPC UA employs a more robust messaging protocol capable of handling larger volumes of data, making it more suitable for high-speed and secure networks.

Sending unverified data to the cloud wastes bandwidth and incurs data ingestion costs and time. The solution to this problem is data validation, semantic contextualization, transforming data into information, and performing operational processing and integration with business or transactional databases and systems, which is an important link in value-adding data. The information obtained after these transformations and processing can provide actionable insights, enabling wise decisions and significantly enhancing operational efficiency while supporting continuous improvement plans, thus contributing to value addition. It should be noted that within the realm of industrial automation, semantic contextualization is strictly regulated and constrained by industry standards, which is also the basic starting point for OPC UA to build industry semantics through supporting information models.

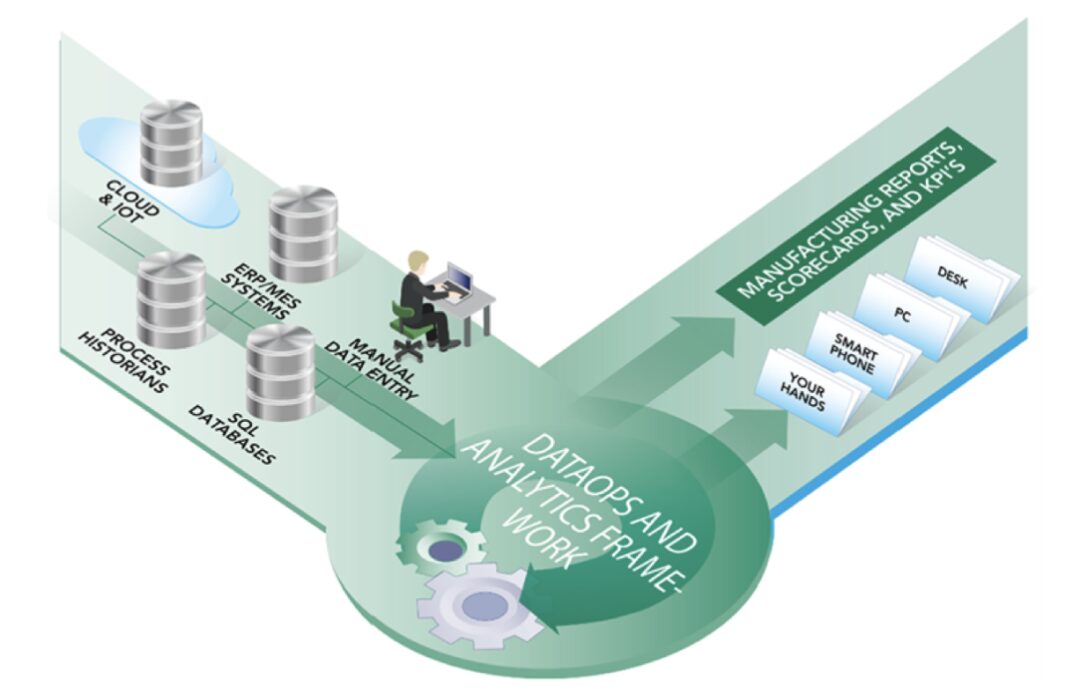

Bridging the data gap requires a comprehensive solution for connectivity that transcends the typical discussions above, namely, the Unified Analysis Framework (UAF). The core functions of this solution include data cleansing, normalizing (representing in standard formats), and semantic contextualization, as well as providing data to various users, including the aforementioned unified namespace UNS. This work should be completed efficiently as close to the data source as possible, rather than sending potentially ineffective or unaggregated data to the cloud for analysis, machine learning, and other value-adding activities.

Building a unified analysis architecture UAF and data transformation processing software with a keen understanding of business and cloud integration for OT. The goal of the UAF solution is to transform data collected at the edge for high-level analysis, artificial intelligence, and machine learning in the cloud. This can be seen as connecting industrial information sources (such as process historical data, business data, manually collected data, etc.) to an information center for various data users. As a center, this software provides a centralized location for the semantic contextualization of data from various sources, data cleansing, and KPI calculation for large-scale execution and management.

Ideally, the UAF solution runs at the edge and encompasses connections to local OT data (DCS, PLC, smart devices, etc.), as well as connections to transactional business data sources (ERP, MES, process historical databases, SQL databases, etc.); performing data transformation processing calculations and semantic contextualization, and publishing results through business layers and the cloud (see Figure 7). The benefit of this approach is that it reduces the cost of data ingestion for cloud systems, but more importantly, it ensures that high-quality data is delivered to the cloud system, rather than wasting time cleaning data in the cloud before analysis. Scalable data governance engineering can be provided by templating cross-business management at different layers.

In data processing software based on the Unified Analysis Framework UAF, the OPC router is a highly configurable software tool designed to integrate various industrial business and IoT data sources using drag-and-drop visual workflows, aimed at reducing engineering time and risks in smart manufacturing, industrial IoT, and digital transformation applications. Key features include:

-

OPC clients connect to OPC UA, OPC DA, and OPC XML-DA servers

-

OPC UA servers, including data access and Method triggers

-

Connections to databases including: Microsoft SQL Server, MySQL, Oracle, MongoDB, InfluxDB, and other ODBC databases

-

File access via SMB (Windows share) and FTP (SSL & plain) for scalable enterprise implementations, storage and forwarding, redundancy, and templates

-

Visual workflows accelerate connections with various data sources

-

SAP certified ERP integration connectors

-

SOAP-Web service connectors for integrating other ERP/MES systems or converting any SOAP Web service data to OPC

4 Conclusion

The success of smart manufacturing and industrial digital transformation plans requires consideration of many factors. The most critical is to solve the acquisition of the correct data, convert it, and transmit it to the right place for further analysis and decision-making. In this critical link, there are currently no corresponding system-complete tooling industrial software domestically, leading to the need for industrial enterprises to develop similar software themselves in their digital transformation planning, which makes work efficiency and success rates difficult to guarantee. The development of widely applicable tooling software should receive urgent attention and promotion.

Research and Development Digital Transformation Triple Jump

Follow “Anshi Asia-Pacific”, don’t miss the wonderful moments