This morning, Sina Mobile Weibo launched a voting activity, details as follows:

The voting deadline is July 15, 2020, at 10:24. The editor has already voted for plastics. Everyone can also hurry to vote to give the plastics industry a good name!

Website:https://vote.weibo.com/h5/index/index?vote_id=2020_1361068_-_12952c

In fact, the application of plastics in mobile phones and electronic products is very extensive.

Figure: Meizu phone with polycarbonate back cover

Today, I will take you into the world of an engineering plastic – polycarbonate (PC)!

Introduction

Content

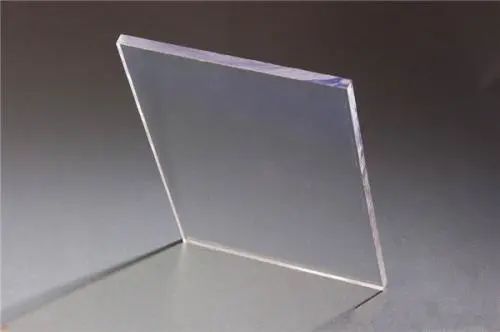

Among the five general-purpose engineering plastics, PC (polycarbonate) is the only product with good transparency. Utilizing this advantage, PC is successfully applied in many fields, including electronics, medical supplies, energy-efficient construction, automotive components, and many rapidly developing industries.

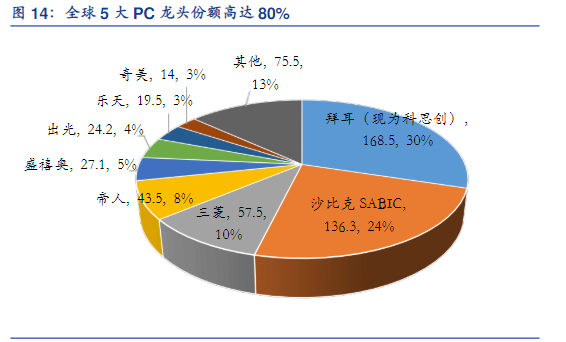

The production process of polycarbonate is quite complex, and only a few large companies worldwide have the production capacity. Domestic manufacturers are all foreign-invested or joint-venture companies. With the increasing demand in the construction and automotive industries in North America and Western Europe, Asia, especially China, is increasing its investment scale in PC production.

Analysis of the Advantages and Disadvantages of PC Applications

Currently, the main production processes for PC are the ester exchange method and the phosgene method. The former struggles to achieve high molecular weight due to the need to distill high-boiling phenol. The latter uses phosgene, a highly toxic raw material, during the reaction process, which presents high demands for technology and safety. Coupled with the toxicity of phenol itself, the entry barrier for PC production gives it a certain level of monopoly.

01

Advantages

PC is an engineering plastic with excellent comprehensive performance, possessing high strength, ductility, and toughness, with outstanding impact strength. Additionally, it has excellent electrical properties and good light transmittance, with a transmittance rate exceeding 90%.

Moreover, its flame retardancy research is quite mature, and many alloy materials choose PC as one of the modifiers. PC used as sheet material has thermal insulation performance 1.25 times that of ordinary glass, impact strength 250 times that of glass, while its density is only half that of glass, thus having enormous application potential in the construction industry.

Furthermore, PC is easy to process with molds and can replace certain automotive parts to achieve weight reduction and energy-saving goals. In particular, the usage of PC in China’s automotive industry only accounts for 5% of the total usage, compared to 20% abroad, indicating significant development space.

In the electronics and electrical industry, the comprehensive excellent performance of PC, including high impact resistance, high heat distortion temperature, insulation, fire resistance, and dimensional stability, keeps its usage continuously growing.

Given that China imports tens of billions of PC each year to meet demand, the market prospects are very optimistic.

02

Disadvantages

Although PC has a wide range of uses, it faces many competitors, and costs remain high, making it replaceable in many application fields.

For instance, low-cost acrylonitrile styrene (SAN) can be used for refrigerator fresh-keeping compartments and protective layers where temperature and impact resistance requirements are not high.

In the field of disposable containers, transparent PP, PET, and PVC are more competitive.

In the field of food utensils, PC products that could be used for water bottles and baby bottles are restricted in certain countries (such as the EU, Canada, and the USA) due to concerns about bisphenol A.

PC products are being forced to move towards better, superior, and high-end fields, which raises higher and broader demands for their new product development capabilities and exploration of application areas.

Main Application Areas of PC

01

Electronics and Electrical Appliances

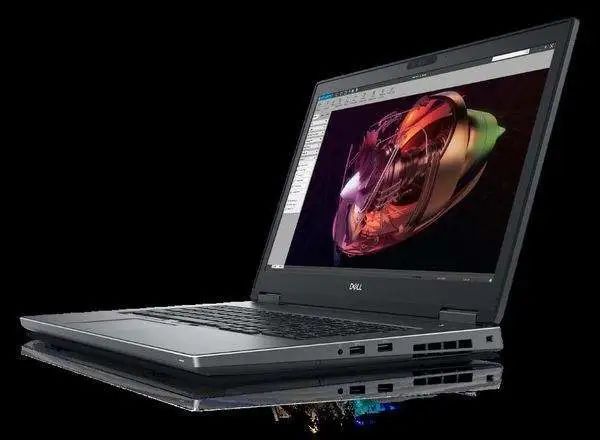

PC has good insulation and strength over a wide range of temperatures and humidity, widely used as the casing, covers, and structural components of computers and various commercial appliances.

It can be made into insulated sleeves, coil frames, electric tool casings, refrigerator freezing drawers, vacuum cleaner parts, etc., and can also be used to manufacture highly precise parts, such as important components in computers, VCRs, televisions, and communication equipment like switches and relays. Due to its excellent optical transparency, light scattering, and dimensional stability, it is applied in diffusion panels for large LCD screens above 42 inches.

PC/ABS alloys not only reduce costs but also have better processability and UV resistance, making them suitable for producing thin-walled parts of injection-molded laptops and notebooks.

02

Building Materials

For a long time, glass has been the main lighting material in modern life, but for large-area building roofs requiring “lightweight and high strength,” the high strength and low density of PC compensate for the heavy and fragile characteristics of glass. Combined with its high safety, easy installation, and strong design capabilities, it occupies a place in contemporary architecture.

Of course, relying solely on the material’s properties is not enough to complete a grand building, just as cement still needs reinforcement. PC, as a building material, incorporates many designs.

With the improvement of PC sheet production processes and technologies, PC hollow sheets, as a new type of material, have injected many new architectural elements into building roofs, facade walls, and curtain walls.

This sheet material, also known as “sunlight board,” can transmit most visible light while blocking most infrared and ultraviolet rays. Natural light passing through this sheet forms a soft diffuse reflection indoors without dazzling, thus being widely used in large spaces such as industrial plants, gymnasiums, exhibition halls, and airports.

In addition, PC sheets are regarded as a green building material due to their excellent energy-saving effects.

03

Automotive Industry

Traditional car windows and sunroofs are being replaced by lighter PC materials. Low density is just one of the reasons for this change. The excellent processing properties of plastics allow automotive designers to continually innovate, combining highly curved PC sheets with car bodies to improve aerodynamic efficiency.

The development potential of PC sunroofs is enormous, with one in every three cars produced in China being equipped with a sunroof or panoramic sunroof. High-heat-resistant polycarbonate can directly perform vacuum metallization for producing condensing lenses and reflective components.

In lighting systems, PC can be used to produce complex-shaped headlights, taillights, and turn signals, improving impact resistance. The use of polycarbonate reduces the weight of front light covers by 0.5 to 1.4 kg compared to inorganic glass.

PC alloys, due to their high mechanical properties and good appearance, are mainly used for exterior and interior parts of automobiles. For example, PC/ABS alloys have excellent heat resistance, impact resistance, and rigidity, as well as good processing flow and paintability, making them ideal materials for manufacturing automotive dashboards. Dashboards made from them require no surface pre-treatment and can be directly spray-painted with soft topcoats or coated with PVC films.

04

Medical Devices

Typical medical applications include high-pressure syringes, disposable dental tools, surgical masks, blood oxygenators, blood collection devices, blood separation devices, surgical instruments, kidney dialysis equipment, venous components, and medical centrifuges.

Being able to withstand high-energy radiation and high-temperature sterilization without losing physical properties and discoloration, as well as improving chemical resistance to prevent cracking, are key issues for the expanded application of PC in this field.

Bayer has launched various new medical products, among which Makrolon® Rx2440 is a new type of transparent, high-flow medical-grade PC material with suitable biocompatibility, applicable to various medical devices, such as intravenous injection, respiratory, surgical, kidney treatment, and more.

Additionally, PC can also act as a solvent in anti-tumor treatments and cleaners. The durability and chemical resistance of this medical polycarbonate product help prevent cracking, allowing medical professionals to safely inject drugs into cancer patients.

05

Other Fields

PC can also be used in films, optical lenses, and packaging fields.

The thinnest film reaches 0.03 mm, is odorless, non-toxic, highly transparent, colorless or slightly yellow, and has many functions, with differences in flame retardant grade, printing grade, scratch resistance, and anti-static properties. It can be used for insulation in power systems, special printing, and window lenses for electronic products like mobile phones.

Optical-grade PC can be used to make optical lenses for high-end cameras, microscopes, telescopes, and glasses, possessing excellent impact resistance.

In packaging, it is mainly used for large-capacity reusable water bottles and food utensils.

Conclusion

Humanity is in the era of new materials, and the development and utilization of materials are issues that every materials scientist is concerned about and thinking about.

PC plastic stands out due to its excellent mechanical, optical, and thermal properties, especially in high-end applications such as electronic products, automotive components, medical devices, and modern construction, where the processes and technologies are becoming increasingly mature, providing strong support for its future development.

Driven by economic globalization, the continuous increase in material demands will inevitably promote the sustained development of PC products, which possess both internal and external competitiveness.

1

END

1

Chain Plastic Network has established a PC plastic exchange group, and industry insiders are welcome to join our group chat to share the latest industry dynamics and exchange the latest information~

Welcome

Join

Us

Some sources: Paper “Applications and Research Progress of Polycarbonate in Modern Plastic Industry” by Dou Liyan, Wang Limei, Jilin University of Architecture