Abstract: In today’s society, electric power resources are one of the most important energy resources, and people’s dependence on electric power is gradually increasing. To date, no one’s life or work can be separated from electric power resources, which has led to a significant increase in the prevalence of power systems. Power systems have a very high utilization and penetration rate, so a stable power system is essential for improving people’s quality of life and work efficiency. In areas with high electrical loads, the temperature of high-voltage switchgear can rise, leading to a decrease in the enclosure’s integrity, which affects the operation of electrical equipment and subsequently reduces the stability and safety of the power system. Currently, traditional monitoring methods using electrical contacts are commonly employed for temperature monitoring of high-voltage switchgear. However, this method is influenced by the electrical contacts, which reduces the accuracy of monitoring and heavily relies on infrared temperature sensors, resulting in high costs that limit widespread application.

Keywords: High-voltage switchgear; Online monitoring; Wireless temperature measurement

0 Introduction

In a power system, there are multiple components and devices, and each part and device must maintain a stable working state. Any failure in one link can lead to the paralysis of the entire power system. Among these, high-voltage switchgear is one of the most important electrical devices, primarily responsible for controlling and protecting the operation of the power system. Currently, the vast majority of high-voltage switchgear adopts a closed structure, which not only leads to significant heat accumulation but also poses certain obstacles to monitoring and maintenance. If the temperature within the high-voltage switchgear cannot be controlled to a reasonable range in a timely manner, excessively high temperatures may trigger fires, ultimately causing irreparable losses to the power system. Therefore, a scientific and reasonable temperature monitoring system for high-voltage switchgear can effectively enhance the stability and safety of the power system, ensuring its efficient operation.

Current temperature monitoring methods for high-voltage switchgear mainly include CCD camera monitoring, temperature-sensitive wax monitoring, and infrared monitoring. Although these methods can monitor temperature, they all have serious drawbacks, namely, they cannot monitor other conditions such as the operating environment and load, and the single monitoring index limits the effectiveness of monitoring. Therefore, designing a monitoring system capable of comprehensively monitoring various indicators is essential. The system designed in this paper aims to address the issues and shortcomings of traditional high-voltage switchgear monitoring methods, achieving a more comprehensive monitoring effect while ensuring a simple structure, ease of operation, and reliable performance, thereby reducing various power system accidents and improving the stability of the power system.

1 Overview of High-Voltage Switchgear

High-voltage switchgear is one of the important electrical devices in the operation of power systems, primarily composed of circuit breakers. Manufacturers design it according to the wiring diagrams of different electrical systems, encapsulating all relevant high and low voltage electrical devices, lines, and conductors within a metal cabinet, serving as a device for distributing electrical energy in the power system.

When designing the structure of high-voltage switchgear, it must have the “Five Prevents”: 1. Prevent misoperation; 2. Prevent short circuits; 3. Prevent load switching; 4. Prevent isolation; 5. Prevent accidental grounding while energized.

Currently, the vast majority of high-voltage switchgear can be classified into two categories based on the installation method of the circuit breaker: withdrawable and fixed types. Withdrawable high-voltage switchgear is mainly used on handcarts due to its good interchangeability, ensuring the stability of power delivery. Fixed high-voltage switchgear, on the other hand, has all electrical devices installed in a fixed manner, thus lacking mobility but offering greater economic advantages.

Based on the internal structure of different high-voltage switchgear, they can be divided into three main categories: metal-enclosed switchgear, metal-segregated switchgear, and metal-enclosed box-type and open switchgear. Different structures of high-voltage switchgear have different internal compositions and advantages and disadvantages. Metal-enclosed switchgear is mainly composed of circuit breakers, busbars, etc., as these components are installed in a metal-enclosed compartment, hence the name. Metal-segregated switchgear shares significant similarities with metal-enclosed switchgear, as its metal components are also installed in compartments, but it has protective non-metallic partitions for better protection. Metal-enclosed switchgear has a protective outer shell made of metal, while open switchgear exposes some equipment, resulting in lower enclosure integrity.

2 System Design Requirements

2.1 Size Requirements

For the vast majority of high-voltage switchgear, the internal space is very limited, making it difficult to install large monitoring devices. Therefore, when designing the monitoring system, it is essential to minimize the size of the monitoring equipment to ensure sufficient internal space within the high-voltage switchgear.

2.2 Insulation Performance Requirements

High-voltage switchgear contains high currents and voltages. If insulation and safety protection are not adequately addressed, it can easily lead to internal short circuits or accidental touch incidents. Therefore, it is necessary to enhance the insulation performance of the monitoring equipment to eliminate the possibility of accidents.

2.3 Stability Requirements

The temperature monitoring system is responsible for monitoring the internal temperature of the high-voltage switchgear. This monitoring requires not only real-time operation but also accurate data collection. Therefore, when designing the temperature monitoring system, it is crucial to ensure that the monitoring equipment has sufficient stability to guarantee the scientific and effective results of the monitoring. Additionally, due to the high accuracy requirements, the monitoring equipment should be regularly checked and maintained. The design of the monitoring equipment should also facilitate maintenance to reduce the workload and operational difficulty for maintenance personnel, improving the usability of the equipment.

3 Overall System Scheme

The temperature monitoring system for high-voltage switchgear consists of three parts: temperature acquisition devices, data computing devices, and monitoring controllers, each performing its respective functions and playing a vital role.

The temperature acquisition device collects the air temperature within the high-voltage switchgear, including temperature sensors, microcontrollers, and information transmitters. Generally, the temperature acquisition device is installed on the circuit breaker of the high-voltage switchgear, responsible for detecting the temperature of the circuit breaker contacts and transmitting the data to the monitoring controller via data transmission equipment to complete the temperature acquisition task.

The data computing device includes components such as processors, displays, and alarms. Most data computing devices are installed on the door of the high-voltage switchgear to calculate the acquired temperature. After processing the data, the results are displayed on the monitor for staff to access relevant data.

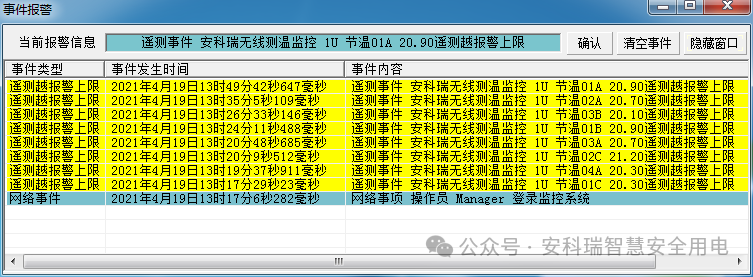

The monitoring controller is equipped with temperature monitoring analysis and statistics software, which can analyze and compute the temperature data obtained from the temperature acquisition device and store the data. When the temperature exceeds the system’s set upper limit, it will promptly issue a warning to inform staff that the temperature has exceeded the standard.

The temperature monitoring analysis and statistics software consists of four components: intelligent analysis system, real-time data system, UI interface, and data transmission.

The intelligent analysis system is the core of the entire temperature monitoring analysis and statistics software. It utilizes internal computing and analysis cores to command the operation of the entire software, including real-time monitoring, data statistics, and warning information management. The intelligent analysis system can intelligently analyze the data obtained by the monitoring system and predict the internal conditions of the high-voltage switchgear by dynamically adjusting the warning thresholds to monitor the temperature of the high-voltage switchgear.

The real-time data system provides a fast and scientific data access channel for the analysis and statistics software. It employs shared storage technology, allowing each module within the software to extract real-time data through standard interfaces, ensuring that each module can perform its maximum function and strictly control various indicators within the high-voltage switchgear.

The UI interface, as the name suggests, facilitates interaction and information exchange between the software and users. It accurately and visually reflects the data and conditions obtained by the software to users, thereby fulfilling the monitoring system’s purpose. The UI interface often employs a graphical interface to enhance usability and reduce the difficulty of operation and learning for users. Users can quickly and conveniently use the UI interface to query various data within the high-voltage switchgear, such as real-time temperature, statistical charts, and analysis results.

The data transmission system can transmit and report data collected and analyzed by other modules and can transfer data obtained from the temperature monitoring analysis and statistics software to the storage system for better data preservation, facilitating future retrieval.

4 Acrel Wireless Temperature Measurement System

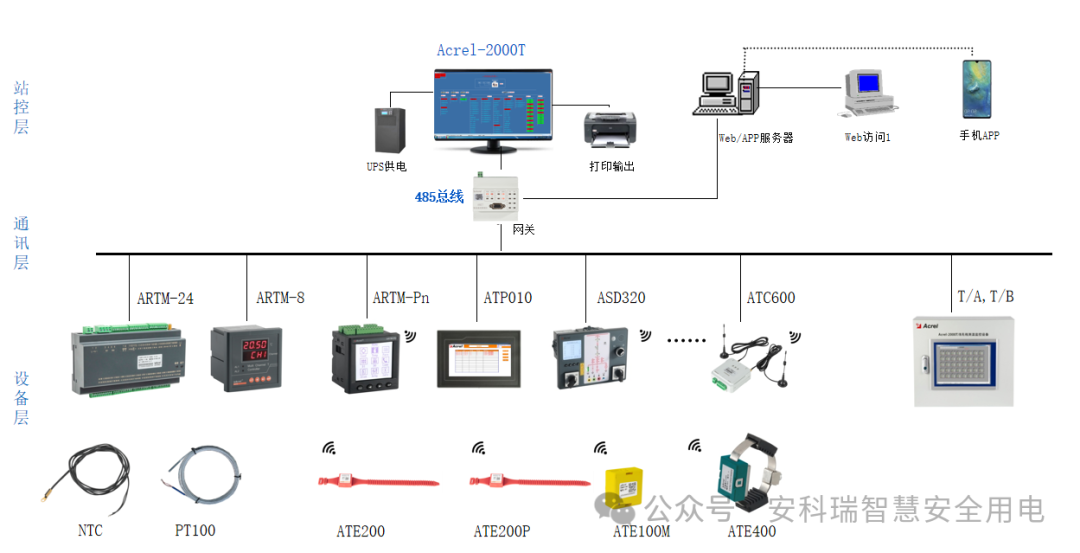

4.1 System Structure

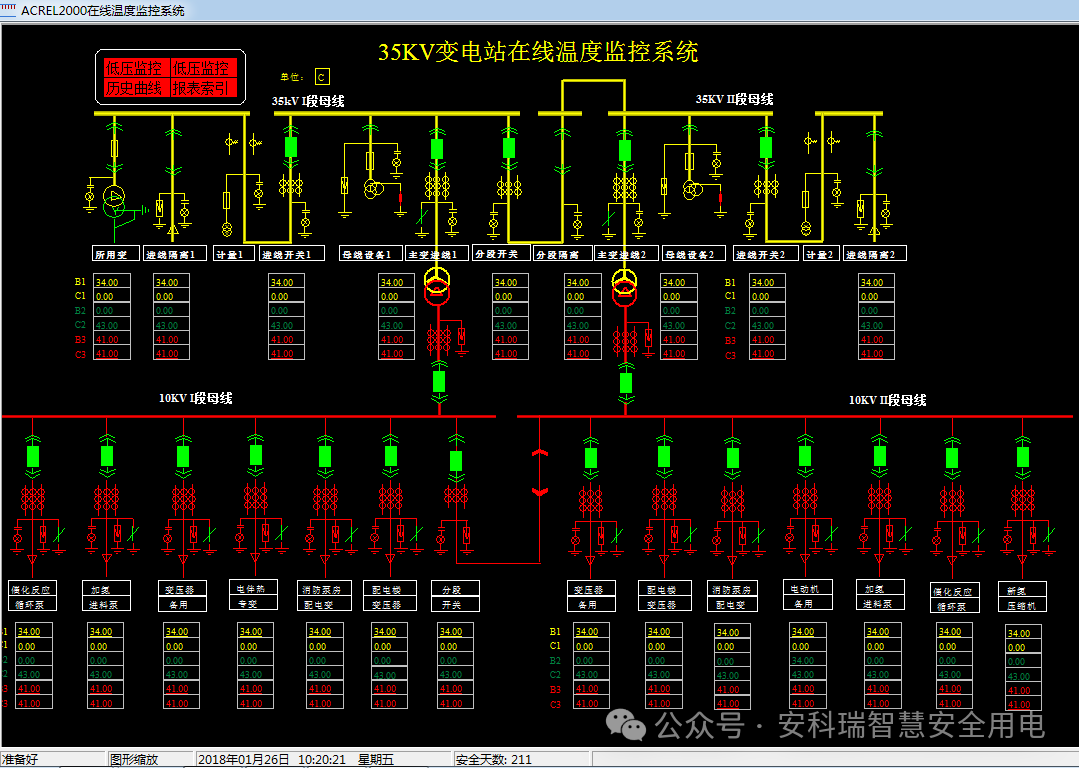

The Acrel-2000T wireless temperature monitoring system communicates directly with the equipment in the interval layer via RS485 bus or Ethernet. The system design adheres to international standards such as Modbus-RTU and Modbus-TCP, significantly enhancing safety, reliability, and openness. This system features remote signaling, remote measurement, remote control, remote adjustment, remote setting, event alarms, curves, bar charts, reports, and user management functions, enabling monitoring of the operational status of the wireless temperature measurement system and achieving rapid alarm response to prevent serious faults.

Temperature Online Monitoring System Structure Diagram

4.2 System Functions

The temperature measurement system host Acrel-2000T is installed in the monitoring room and can remotely monitor the temperature status of all switchgear operating within the system. The system has the following main functions:

- Temperature Display: Displays the real-time values of each temperature measurement point within the distribution system and allows remote data viewing via computer WEB/mobile APP.

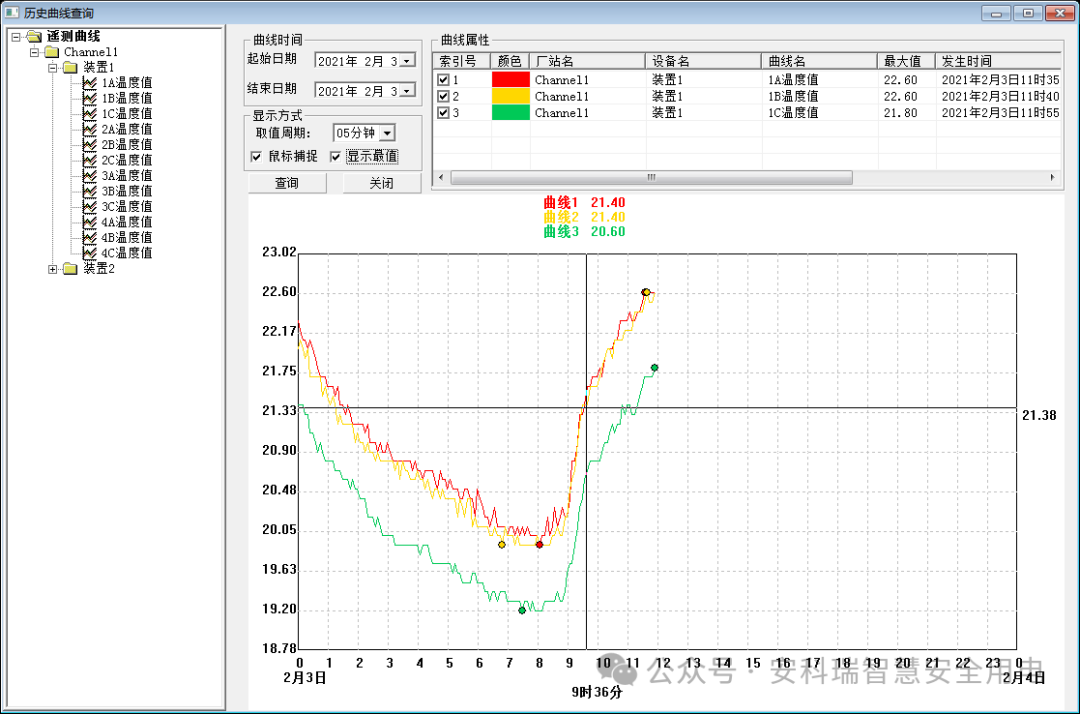

- Temperature Curve: View the temperature trend curve of each measurement point.

- Operational Reports: Query and print temperature data for specified times at each measurement point.

- Real-Time Alarms: The system can issue alarms for abnormal temperatures at each measurement point. It features real-time voice alarm capabilities, issuing voice alerts for all events, with alarm methods including pop-ups, voice alerts, and SMS/APP push notifications to promptly remind on-duty personnel.

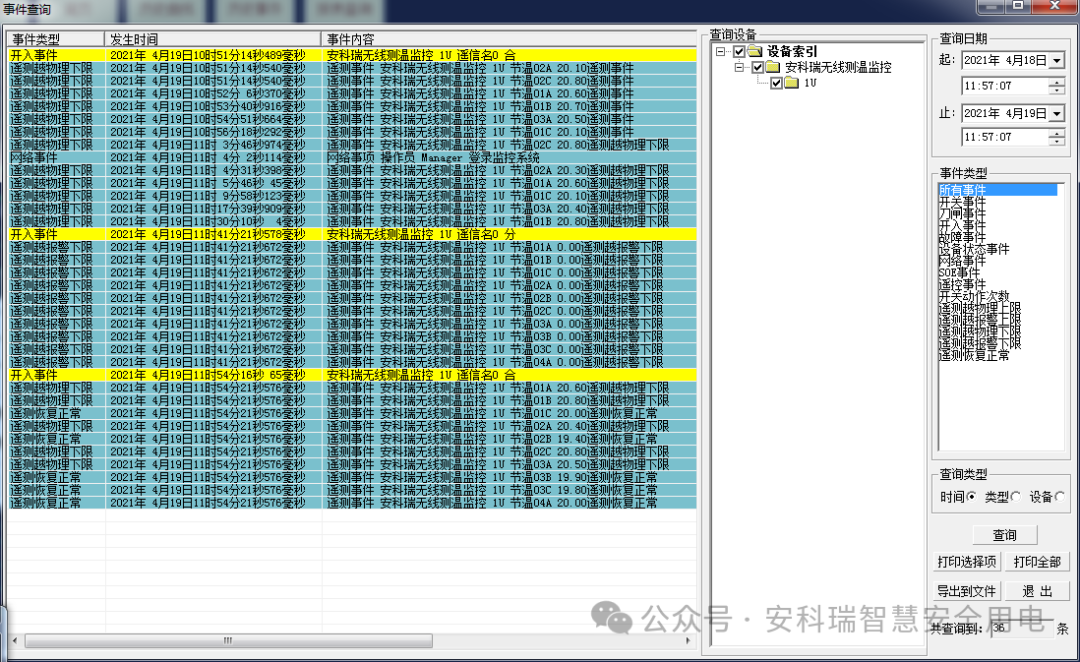

- Historical Event Query: Records of events such as temperature exceedances can be stored and managed, facilitating users’ historical tracing of system events and alarms, query statistics, and accident analysis.

4.3 System Hardware Configuration

The temperature online monitoring system mainly consists of temperature sensors and temperature acquisition/display units at the device layer, an edge computing gateway at the communication layer, and the temperature measurement system host at the station control layer, achieving online temperature monitoring of key electrical parts in the power distribution system.

|

Name |

Appearance |

Model |

Parameter Description |

|

System Configuration Software |

|

Acrel-2000/T |

Hardware: 4G memory, 500G hard disk, Ethernet port. Display: 21 inches, resolution 1280*1024. Operating System: Windows 7 64-bit Simplified Chinese Ultimate Edition. Database System: Microsoft SQL Server 2008 R2. Communication Protocol: IEC 60870-5-103, IEC 60870-5-104, Modbus RTU, Modbus TCP, and other international standard communication protocols. |

|

Intelligent Communication Management Machine |

|

Anet-2E4SM |

Universal gateway, 2 Ethernet ports, 4 RS485 ports, optional 1 LORA, with power-on alarm function, supporting 485, 4G module expansion. |

|

Wireless Temperature Centralized Acquisition Device |

|

Acrel-2000T/A |

Wall-mounted installation Standard configuration with one 485 interface and one Ethernet port Built-in buzzer alarm Cabinet size 480*420*200 (mm) |

|

Acrel-2000T/B |

Hardware: 4G memory, 128G hard disk, Ethernet port Display: 12 inches, resolution 800*600 Operating System: Windows 7 Database System: Microsoft SQL Server 2008 R2 Optional Web platform/APP server Cabinet size 480*420*200 (mm) |

|

|

Display Terminal |

|

ATP007 ATP010 |

DC24V power supply; one upstream RS485 interface; one downstream RS485 interface; Can receive 20 ATC200/1 ATC400/1 ATC450-C. |

|

ARTM-Pn |

Panel size 96*96*17mm, depth 65mm; opening 92*92mm; AC85-265V or DC100-300V power supply; One upstream RS485 interface, Modbus protocol; Can receive 60 ATE100/200/300/400; compatible with ATC200/300/450. |

|

|

ASD320 |

|

ASD300 |

Panel size 237.5*177.5*15.3mm, depth 67mm; opening 220*165mm; AC85-265V or DC100-300V power supply; One upstream RS485 interface, Modbus protocol; Can receive 12 ATE100/200/300/400; compatible with ATC200/300/450. |

|

Smart Temperature Inspection Instrument |

|

ARTM-8 |

Opening 88*88mm for embedded installation; AC85-265V or DC100-300V power supply; One upstream RS485 interface, Modbus protocol; Can connect 8 PT100 sensors, suitable for temperature measurement at low-voltage switchgear electrical contacts, transformer windings, etc. |

|

ARTM-24 |

35MM rail-mounted; AC85-265V or DC100-300V power supply; One upstream RS485 interface, Modbus protocol; 24 channels of NTC or PT100, 1 channel for temperature and humidity measurement, 2 relay alarm outputs, suitable for temperature measurement at low-voltage electrical contacts, transformer windings, etc. |

|

|

Wireless Transceiver |

|

ATC450-C |

Can receive data from 60 ATE100/ATE100M/ATE200/ATC400/ATE100P/ATE200P sensors. |

|

ATC600 |

ATC600 has two specifications; ATC600-C can receive data from 240 ATE100/ATE100M/ATE200/ATC400/ATE100P/ATE200P sensors. ATC600-Z serves as a relay for transparent transmission. |

|

|

Battery-Powered Wireless Temperature Sensor |

|

ATE100M |

Battery-powered, lifespan ≥ 5 years; -50℃~+125℃; accuracy ±1℃; 470MHz, open distance 150 meters; 32.4*32.4*16mm (L*W*H). |

|

ATE200 |

Battery-powered, lifespan ≥ 5 years; -50℃~+125℃; accuracy ±1℃; 470MHz, open distance 150 meters; 35*35*17mm, L=330mm (L*W*H, three-color strap). |

|

|

ATE200P |

Battery-powered, lifespan ≥ 5 years; -50℃~+125℃; accuracy ±1℃; 470MHz, open distance 150 meters, protection level IP68; 35*35*17mm, L=330mm (L*W*H, three-color strap). |

|

|

CT-Powered Wireless Temperature Sensor |

|

ATE400 |

CT-powered, starting current ≥ 5A; -50℃~125℃; accuracy ±1℃; 470MHz, open distance 150 meters; Alloy piece fixed, power extraction; three-color shell; 25.82*20.42*12.8mm (L*W*H). |

|

Wired Temperature Sensor |

|

PT100 |

Used for low-voltage contact temperature measurement; specific packaging, accuracy, wire system, wire material, and length should be discussed with the supplier; For temperature measurement of transformers and motor windings, it is recommended to embed PT100 inside the transformer or motor. |

|

NTC |

Used for low-voltage contact temperature measurement; specific packaging, accuracy, wire system, wire material, and length should be discussed with the supplier; For temperature measurement of transformers and motor windings, it is recommended to embed NTC inside the transformer or motor. |

5 Conclusion

To ensure the normal operation of the power system, it is crucial to emphasize the online temperature monitoring of high-voltage switchgear and design targeted monitoring systems, allowing the monitoring system to function properly and maintain the temperature within the high-voltage switchgear at a reasonable range, avoiding various accidents that could impact the stability of the power system.

For more detailed product information, please feel free to inquire.