“PLC Network Optimization: Three Tricks to Perfect Network Structure for Smooth Data Transmission!”

Hello everyone! Are you still going crazy over PLC networks lagging like a PowerPoint presentation? Every time there’s a data delay, it feels like waiting for takeout? Today, we are going to tackle this “network speed anxiety” in the industrial sector!

▶ A Bloody Lesson

Last year, a chemical plant’s PLC network failed, causing a 3-hour shutdown that directly resulted in a loss of 3 million! Even worse, an automotive factory scrapped an entire batch of car bodies due to a 0.1-second synchronization error. The most heartbreaking was a food factory, where a production line lag caused yogurt to over-ferment—turning perfectly good yogurt into cheese…

▶ The Life and Death Speed of Neural Networks

The PLC network is like the nervous system of a factory, with signal delays comparable to a cerebral thrombosis! Here are a few critical scenarios:

Robotic arms dancing like they have epilepsy (delays > 2ms cause direct deformation of actions)

Sensors becoming presbyopic (data packet loss turns quality control into a lottery)

Monitoring screens lagging like a comic strip (always spinning in circles at critical moments)

▶ Three Axes of Network Optimization

First Axe: Wiring Mysticism

Don’t think you can just pull network cables anywhere! Remember the “Three No Principles”:

Do not run cables next to power cables (interference is more troublesome than a mother-in-law)

Do not make right-angle turns (signals hitting walls will get confused)

Do not use network cables as clotheslines (stretching over 5% turns them into antennas)

Second Axe: Protocol Selection

How to choose among the three major protocols? Check out this “comparison chart”:

Third Axe: Device Enhancement

A certain factory in Shenzhen’s black technology had me slapping my thigh—

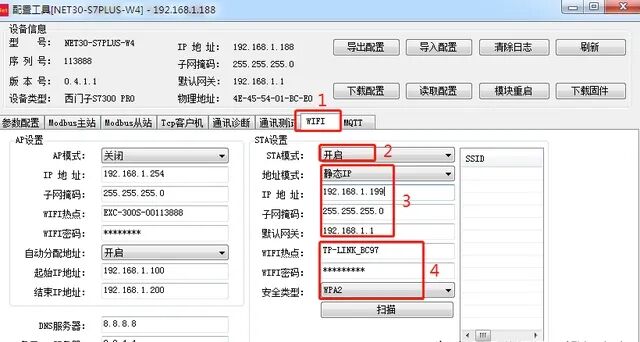

PLC with built-in WiFi 6, networking is easier than connecting Bluetooth headphones

Stable transmission even at -40°C (tested in cold storage, more frost-resistant than penguins)

15 types of protocols automatically translated, smoother than simultaneous interpretation

▶ Pitfall Guide (Blood and Tears Edition)

❗ Never trust “universal converters” (a certain factory was tricked into a PLC strike)

❗ Ground wires are not decorations (random grounding is like installing a lightning rod on equipment)

❗ Don’t let the IT department touch the OT network (their reboot magic can be fatal)

▶ Visible Improvement After Transformation

Check out the results:

Automotive factory: Equipment synchronization error reduced from 5ms to 0.5ms

Chemical plant: Data packet loss rate plummeted from 15% to 0.01%

Photovoltaic power station: Daily steps for maintenance personnel reduced from 20,000 to 8,000 (no more running around the factory)

▶ Step-by-Step Transformation Route

Network health check (first, take a CT scan of the existing network)

Solution selection (like choosing a marriage partner, it needs to be a good match)

Small-scale trial (first test one production line)

Full factory promotion (remember to prepare the veteran workers psychologically)

Soul-searching Three Questions:

Is your equipment still using “old-age” networks?

Is troubleshooting harder than solving a case?

Do you want your boss to see you and think of bonuses?

End of Article Surprise:

If likes exceed 500, I will reveal my secret “Industrial Network Debugging Manual”! The first three commenters will receive a limited edition “Protocol Conversion Jargon Dictionary”—so you can communicate with German engineers without hesitation!

Golden Quote to End:

A good PLC network should be like love—there should be a mutual understanding, and responses should be instantaneous!