In today’s industrial era characterized by interconnectivity and seamless data sharing between devices, the demand for accelerometers with features such as wireless transmission, digital output (like IO-Link), and sensor-level data edge processing is increasingly becoming a trend in the field of preventive maintenance. However, regardless of how advanced the technology for sensor data output becomes, the two most trusted sensing technologies in machine health monitoring remain: piezoelectric sensing and capacitive MEMS (Micro-Electro-Mechanical Systems).

In the consumer electronics sector, MEMS accelerometers are popular due to their low cost and frequency range down to 0Hz. However, the requirements for sensors in the field of mechanical health monitoring are vastly different. Wideband detection capability is crucial for achieving early fault alarms. The low-frequency vibrations detectable by MEMS sensors are often associated with late-stage rolling bearing failures, thus relying solely on MEMS accelerometers for mechanical health monitoring may lead to delayed alarms and significant equipment damage. To ensure early detection of potential hazards and avoid catastrophic failures, piezoelectric sensors have become the preferred choice.

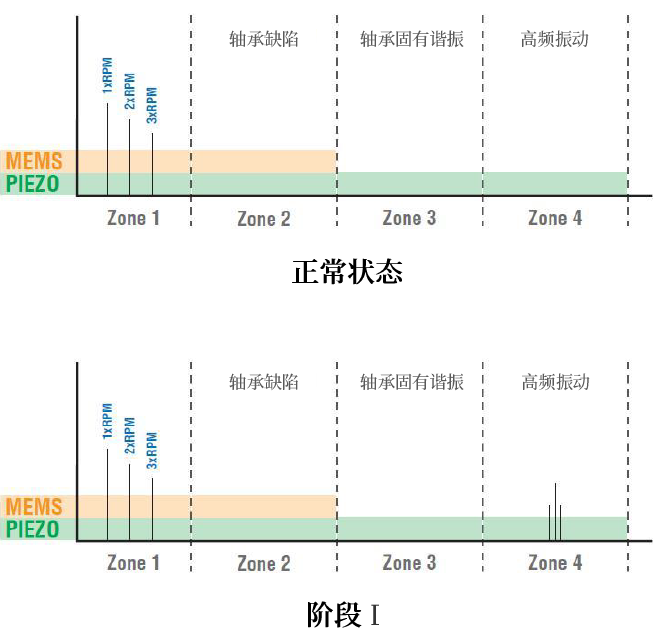

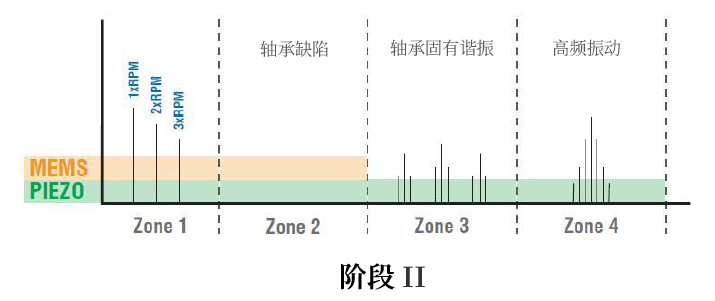

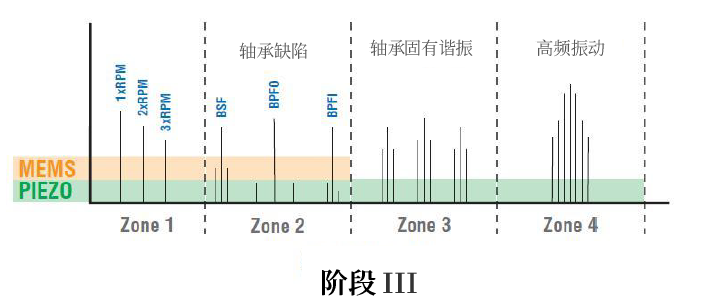

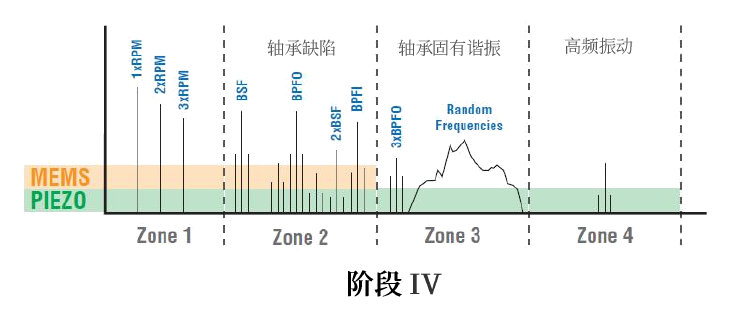

This article will compare these two mainstream sensor types and evaluate their performance within the frequency ranges corresponding to common faults. To illustrate the importance of the sensor’s wideband detection capability, we will consider the vibration frequencies related to the four stages of bearing failure.

In the initial stage of bearing failure, signs of deteriorating condition begin to appear, manifested as collisions between metal parts, usually caused by a lack of lubrication. At this stage, the vibration frequency of the bearing falls within the ultrasonic frequency range, approximately 1200k to 3600k CPM (20,000~60,000Hz), and can typically only be detected using peak energy or impact pulse instruments. Assessing lubrication or alignment conditions early in the failure can prevent significant issues. Conversely, if no intervention occurs, the damage will progress into the second stage of failure.

In the second stage of failure, the damage from the first stage becomes significant. Minor defects cause the installed accelerometer to produce a resonant response, with a frequency range of approximately 120k to 480k CPM (2,000~8,000 Hz). Wear or damage becomes visible on the bearing surface, potentially beginning to affect the overall lifespan of the bearing. At this stage, the bearing may start to exhibit noise or increased vibration, and sometimes the temperature may rise. The bearing is likely to require replacement, and the resulting machine downtime may lead to decreased output. Therefore, early detection and resolution of issues at this stage is crucial to prevent further damage and machine failure.

As bearing failure progresses to the third stage, the damage becomes severe, and the performance of the bearing significantly deteriorates. Increased vibration and rising operating temperatures are common manifestations at this stage. Sideband frequencies may appear near the defect frequency. Critical machines should undergo additional vibration analysis to assess the damage. If no human intervention occurs at this stage, the risk of catastrophic failure and corresponding machine damage is significantly heightened.

The fourth stage is the catastrophic stage, the final and most severe stage of bearing defect development. At this stage, the bearing completely fractures or loses all functionality, rendering it unable to bear loads or operate effectively. The frequencies corresponding to bearing defects concentrate in the low-frequency range below 5000Hz. Catastrophic failures can lead to longer downtimes, higher repair costs, and potential collateral damage to surrounding machinery.

Fundamentally, the ability to detect high-frequency vibrations means the difference between simple preventive maintenance and high-cost repairs. Unlike MEMS sensors, piezoelectric accelerometers can accurately measure vibrations across a wide frequency range, including high frequencies. This capability is extremely useful for machine health monitoring applications due to its ability to detect minor vibration anomalies early in the deterioration of equipment status.

Machine health monitoring aims to identify potential failure hazards and prevent them from developing into catastrophic events. By using piezoelectric sensors, technicians can detect and analyze vibrations across a frequency range that includes both low and high frequencies. The wideband characteristics of piezoelectric sensors make them suitable for various machine health monitoring applications, including rotating machinery, industrial equipment, and structural condition monitoring. Their ability to detect early minor vibration anomalies enables maintenance technicians to take timely action to prevent major failures and reduce downtime.

In addition to wideband performance, piezoelectric sensors also offer excellent reliability and accuracy. With reliable and precise data, maintenance technicians can gain a comprehensive understanding of machine health, make informed decisions, optimize maintenance schedules, avoid unplanned downtime, and reduce maintenance costs.

This article is excerpted from

“Piezoelectric Sensors: The Superior Choice for Early Fault Detection in Machine Health Monitoring,” Written By Matthew Negaard, PCB Piezotronics.

About PCB

PCB Piezotronics, Inc. was established in 1967 and is headquartered in Buffalo, New York, USA. It has been in China for over 30 years. In 2013, it established its subsidiary in China: PCB Piezotronics Technology (Beijing) Co., Ltd., and has sales and technical support personnel in several cities to provide nearby services.

PCB® specializes in the research and development of piezoelectric measurement technology and is a high-tech company engaged in the research, development, and manufacturing of impact, vibration, force, pressure, strain, torque, and acoustic sensors and measuring instruments. Its products are widely used in aerospace, shipbuilding, petrochemical, hydropower, electric power, light industry, transportation, and vehicles, and are renowned worldwide. In addition to general products, PCB® also manufactures custom products according to user requirements to meet the needs of different applications and customer groups. Customer satisfaction is our consistent service tenet.

Since April 2021, PCB® has been a subsidiary of Amphenol Corporation (NYSE: APH).