Click the blue text

Follow us

Shanghai Society of Civil Engineering

Editor’s Note

2022 was referred to as the year of development for 3D printing technology in Japan. Major construction companies such as Obayashi Corporation, Shimizu Corporation, Taisei Corporation, and Maeda Corporation have developed their own 3D printers and specialized materials.

On the other hand, some overseas 3D startups have collaborated with construction companies to develop technologies and achieved certain results.

Today, I will take you to look at the materials, equipment requirements, and the current global industry situation of 3D printing~~~

Materials and Equipment Requirements for 3D Printers

1

Material Requirements and Development Status

3D construction printers commonly use cement materials. The printer’s layering path can be formed and controlled in two ways: one for shaping and one for linked control printing, which requires high standards for the printing materials: the mortar used for printing must have high fluidity when pumped, its viscosity after being ejected must prevent collapse (thixotropic), and it must solidify quickly without collapsing under the weight of upper materials. To print stably, it is necessary to optimize the material formula and printer control, among other factors.

Currently, Japan has developed specialized materials and is exploring how to apply them in civil engineering and construction. Major manufacturers such as France’s Saint-Gobain, Switzerland’s Holcim, and Mexico’s CEMEX are also committed to developing materials for 3D construction printers.

2

Equipment Situation Overview

The types of 3D printers can be mainly divided into the following two:

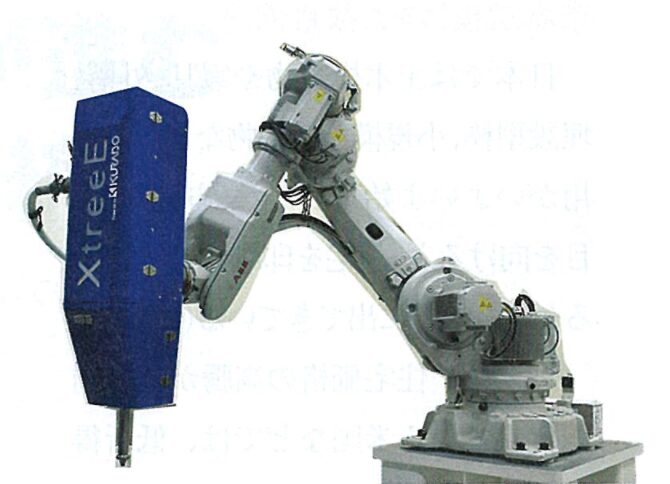

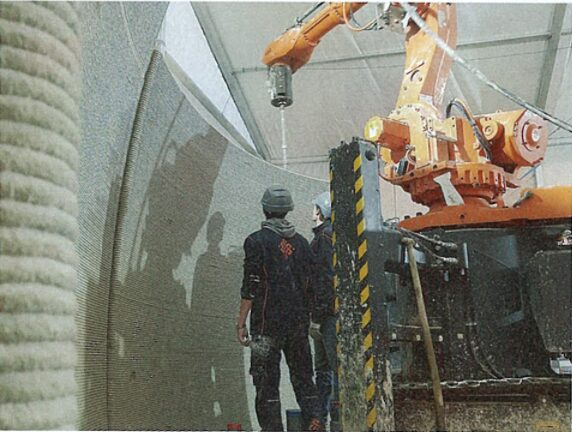

① Printers based on industrial robotic arms. This type of equipment is easy to control and suitable for printing finely designed structures. However, the size that can be printed at one time is limited; if large structures are to be built, parts need to be printed in segments and then assembled on-site.

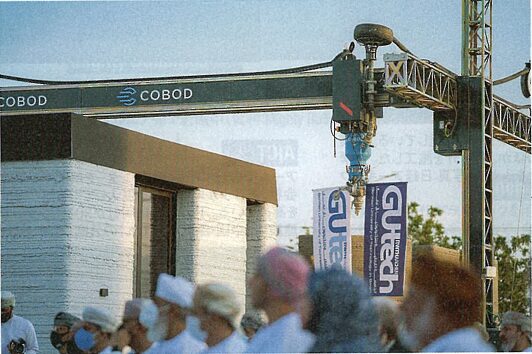

② Gantry-type printers. This equipment is suitable for printing large structures on construction sites. Compared to robotic arm types, it is not good at printing finely detailed designs. There are also types of 3D printers that have nozzles mounted on the front end of cranes.

As an emerging industry, the printing prices for 3D printing also vary with the size of the printed buildings. Generally, market printing costs range from several hundred thousand to over six million yuan for large projects. Since each company develops its own printers and materials, the difficulty of supplying printing materials has also become a major issue.

Many companies around the world have developed 3D printing equipment, and some universities have also joined the research and development, such as ETH Zurich, Eindhoven University of Technology, and Delft University of Technology, which are researching digital construction and production.

Overview of the Global 3D Printing Industry in Construction

Asia & Oceania

Europe

The Americas

Location: China

Company Name: WinSun

A Chinese company engaged in the development of cement material 3D printers and new green building materials using 3D printing technology.

Location: Japan

Company Name: Polyuse

Developing a gantry-type cement material 3D printer. In addition to a warehouse that has already obtained a building permit, a well has also been constructed. Focused on collaboration with universities and companies.

Location: India

Company Name: MiCoB

Developing a cement material 3D printer based on research from the Indian Institute of Technology Gandhinagar.

Company Name: Simpliforge Creations

Developing an arm-type cement material 3D printer.

Company Name: Tvasta

In 2020, India first printed a house using a cement material 3D printer.

Location: UAE

Company Name: BESIX 3D

A division of the Belgian construction company BESIX. The company established a 3D construction printer studio in Dubai, UAE in 2019.

Location: Australia

Company Name: LUYTEN

Used a cement material 3D printer to print houses in Melbourne. Collaborating with the University of New South Wales to develop a printer for building a lunar base.

Company Name: CNC Design

Developing a solution called Virtual Smart Factory (VSF) using a gantry-type cement material 3D printer.

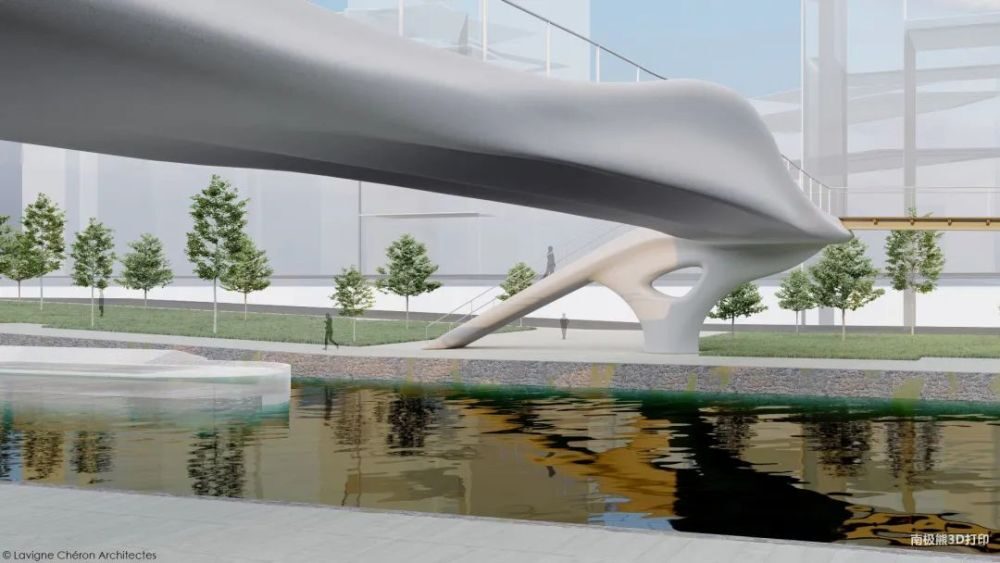

Location: Netherlands

Company Name: MX3D

A developer of metal 3D printers. In 2021, built a steel pedestrian bridge over a canal in Amsterdam, Netherlands. The company is collaborating with Takenaka Corporation.

Company Name: CyBe Construction

An outstanding Dutch startup engaged in cement material 3D printers. Japan’s Kajima Corporation has introduced CyBe Construction’s printers.

Company Name: Vertico

Developing cement material 3D printers. Using mortar and other materials from Swiss chemical manufacturer SIKA.

Company Name: Twente Additive Manufacturing

Providing cement material 3D printers, mainly for residential purposes.

Location: Italy

Company Name: WASP

Developing a large 3D printer in the shape of a crane. Its main feature is the use of natural materials (clay, straw, etc.). The company frequently appears in hot topics, such as printing a pop-up store for Dior in Dubai.

Location: Denmark

Company Name: COBOD International

In the past three years, delivered over 30 gantry-type large cement material 3D printers named BOD2. Funded by the German formwork manufacturer PERI Group. The Nichi-Group has also introduced this printer.

Company Name: WOHN

A startup aimed at printing small-scale houses using waste plastic and glass as raw materials.

Location: France

Company Name: XtreeE

Developing cement material 3D printers. Japan’s Kurabo Company has introduced this technology. Undertook the design and construction order for a 40m long pedestrian bridge.

Company Name: Constructions-3D

Providing cement material 3D printers that can print on construction sites, priced over 60 million yen. The base machine is a small crane.

Location: Finland

Company Name: Hyperion Robotics

Founded in 2019, a startup engaged in cement material 3D printers. Focused on reducing carbon emissions through waste recycling.

Location: Germany

Company Name: Aeditive

A company established in 2019, developing and selling arm-type cement material 3D printers. The company prints reinforced concrete structures by spraying concrete onto the rebar and shaping it with a trowel without using forms.

Location: Austria

Company Name: Concrete 3D

A manufacturer of cement material 3D printers, focusing on printing exterior walls.

Location: Serbia

Company Name: Natura Eco

In addition to gantry and crane types, also developing a giant cement material 3D printer named G.O.L.I.A.T.H.

Location: Slovenia

Company Name: BetAbram

Providing gantry-type cement 3D printers for printing houses.

Location: Switzerland

Company Name: MOBBOT

Unlike cement material 3D printers that layer materials through extrusion, this one uses high-speed spraying of concrete.

Location: UK

Company Name: Ai Build

Mainly targeting aerospace and automotive sectors. More advantageous in software aspects.

Location: USA

Company Name: AICT

Developing a type of arm-based cement 3D printer. The company adds fibers to the mortar to increase tensile strength.

Company Name: Mighty Buildings

Using a special material (LSM) that hardens under ultraviolet light to print modular wall panels, which are then assembled into houses.

Company Name: Branch Technology

Has a technology for printing grids using carbon fiber reinforced plastic. This technology allows filling the voids of freely shaped grids with insulation materials and finishing the surface for use in building exterior cladding materials.

Company Name: Al SpaceFactry

Developing biodegradable materials for printing buildings using materials like corn, reducing waste. Won the NASA Mars Habitat Challenge in 2019.

Company Name: SQ4D

Sold a cement material 3D printed house for about $300,000, causing a stir.

Company Name: Contour Crafting Corporation

Founded by the pioneer of 3D construction printing, Professor Behrokh Khoshnevis from the University of Southern California.

Company Name: Black Buffalo 3D

Engaged in 3D printer business under a Korean company named HN (Old Modern BS&C).

Company Name: ICON

In Austin, Texas, a project is underway to build 100 houses using 30 printers named Vulcan.

Company Name: Apis Cor

Printed the world’s largest building, with a total area of 640㎡ and a height of 9.5m in Dubai.

Swipe up and down to see more

Technical Outlook

3D construction printing not only reduces costs and shortens construction periods but is also a tool that opens up new possibilities for appearance design and structural construction, receiving much attention. Because it does not require construction templates, it is easy to realize the design of large amounts of hollow and curved surfaces.

Irregular pillars printed by Shimizu Corporation

In addition, 3D printers can shape structures with high rationality and minimal material usage, reducing the use of materials like cement and lowering carbon emissions. However, 3D printing also has the disadvantage of being difficult to shape structures that extend upwards. Currently, various parties are researching design methods that conform to the characteristics of 3D construction printers (DfAM, Design for Additive Manufacturing), and developing tools for this purpose.

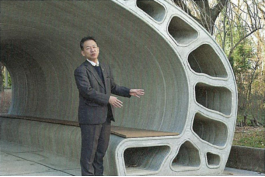

Benches printed by Obayashi Corporation

■ Translator: EriiAmamiya

■ Editor: EriiAmamiya & SS

■ Typesetting: EriiAmamiya

Shanghai Civil Technology 2022(02), full of valuable content

The “Civil Vision” video sharing platform for civil engineers is online!

The 10th International Bridge and Tunnel Technology Conference will be grandly held

2022 Membership Fee Payment Notice

Statement:Unless otherwise noted as original or source, this account’s content comes from the internet, organized by the Shanghai Society of Civil Engineering, copyright belongs to the original author, and thanks to the original author. If there is any infringement, please contact us to delete or take related action!

Articles and images are not allowed to be reprinted or used commercially without permission