01

Research Background

Under the background of carbon neutrality, the transformation of automated factories into intelligent factories significantly promotes the high-end, intelligent, and green development of the papermaking industry. The realization of the papermaking industry’s Internet of Things requires a large number of smart sensing terminal devices. However, the increased energy consumption during the intelligentization of papermaking equipment conflicts with carbon reduction policies, which urgently need to be addressed by the introduction of advanced technologies. The birth of the Triboelectric Nanogenerator (TENG) and its advantages have become an indispensable part of solving the sustainable energy dilemma.

The micro-nano energy collection process in papermaking refers to the conversion of random, irregular, fragmented micro-mechanical energy generated during the pulping and papermaking process into electrical energy through TENG, serving as an emerging research direction for the paper production process. The forms of micro-nano energy in the papermaking process mainly include: vibrations from mechanical equipment, pulp flow, noise waves, and low-grade thermal energy. TENG can be designed specifically for various energy collection and conversion devices according to the source of energy forms, achieving efficient collection and application of micro-nano energy, such as collecting vibration energy from pulping and papermaking equipment through contact between solids or collecting energy from liquid flow through contact between liquids and solids.

Recently, Academician Wang Shuangfei’s team proposed an innovative idea for micro-nano energy collection and conversion in the papermaking process, clarifying the mechanism of micro-nano energy collection and conversion based on pulp and solids, and constructing a self-powered sensor for real-time monitoring of pulp concentration. This achievement, titled “Micro-Nano Energy Collection in Papermaking Process and Its Application in Self-Powered Pulp Concentration Sensing”, was published in the latest issue of “China Pulp and Paper” journal.

02

Illustrated Guide

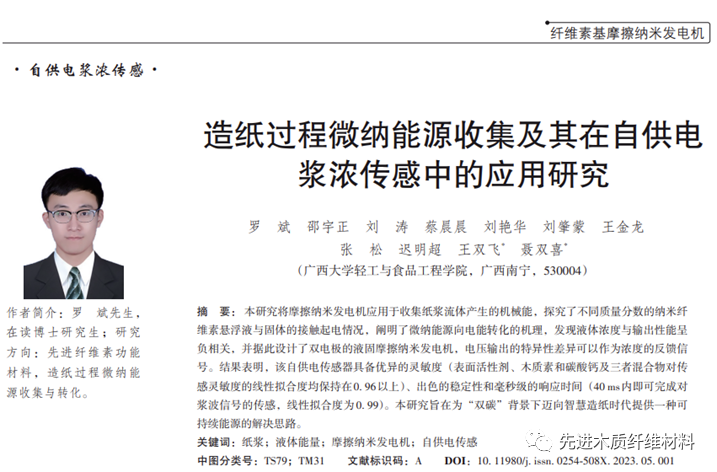

By constructing a liquid-solid mode TENG, energy is collected and converted from the contact electrification between liquids and solids. Based on the relationship between pulp concentration and output voltage, a self-powered pulp concentration sensor was constructed, demonstrating its application scenario in the papermaking white water system.

Figure 1. Application of the self-powered sensor and its charge distribution schematic

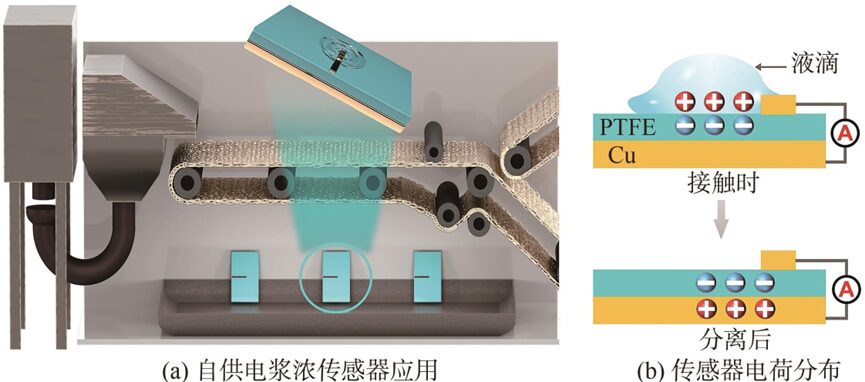

To elucidate the conversion mechanism of micro-nano energy collection in the papermaking process, Figure 2(a) shows a schematic diagram of the electrification mechanism of liquid contact with Polytetrafluoroethylene (PTFE). Since water molecules are the main component in pulp, this process can be explained using the electron cloud model between water molecules and PTFE molecules. Figure 2(e) illustrates the charge transfer of a single-electrode mode TENG; after contact between the liquid and solid, an electric double layer will form at their interface, with positive charges from the liquid disrupting the charge balance between the copper electrode and PTFE, causing charges to flow from the ground wire to the copper electrode to neutralize its internal positive charges, thus forming a current in the external circuit (Figure 2(e) II). When the liquid falls away, the charge balance at the liquid-solid interface is disrupted, prompting negative charges to flow out from the copper electrode through the ground wire, creating a return current.

Figure 2. Operating mechanism and results of the single-electrode TENG

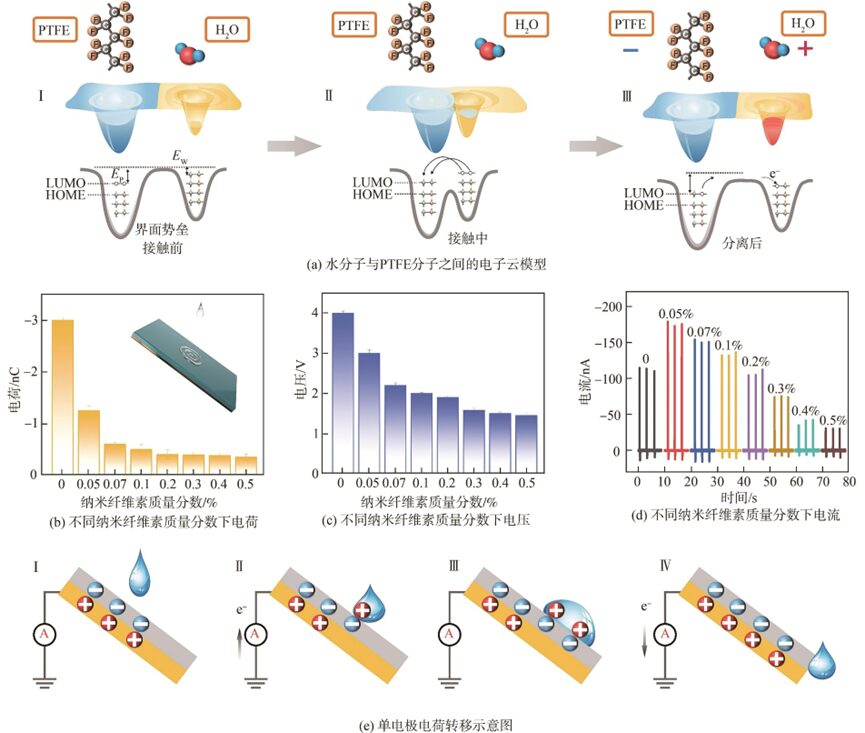

Due to the lower output performance of the single-electrode mode TENG, which is significantly affected by the environment and external circuits, a dual-electrode mode TENG was further assembled (as shown in Figure 3(a)) to enhance the variation in TENG output performance caused by changes in pulp concentration. Figure 3(b) shows the function curve of pulp concentration (X-axis) and electrical signal response value (Y-axis), indicating that this self-powered pulp concentration sensor exhibits good linear fitting. Figure 3(c) demonstrates that the response times of the TENG to liquid contact and separation are 7 ms and 30 ms, respectively, indicating that the sensor has a millisecond-level response time.

Figure 3. Sensing performance and operating mechanism of the self-powered pulp concentration sensor

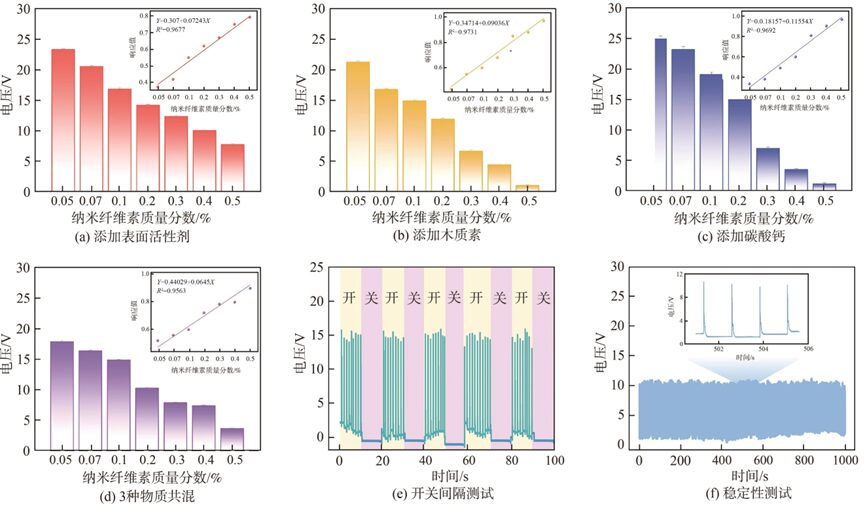

To verify the practical application capability of TENG as a self-powered pulp concentration sensor, the interference of surfactants, lignin, calcium carbonate, and a blend of three substances was studied, adding them to cellulose nanofiber suspensions of different mass fractions to investigate the stability of the sensing signals. The results are shown in Figure 4(a~c); the interference of individual components had little effect on the sensor’s sensitivity, maintaining a linear regression fitting degree of 0.97. The fitting degree of the blend decreased slightly but remained at 0.96 (Figure 4(d)). The results indicate that this self-powered pulp concentration sensor has good anti-interference capability.

Figure 4. Stability of the self-powered pulp concentration sensor

03

Conclusion

This study proposed an innovative idea for micro-nano energy collection and conversion in the papermaking process, clarifying the mechanism of micro-nano energy collection and conversion based on pulp and solids, and constructing a self-powered sensor for real-time monitoring of pulp concentration. The results indicate that this self-powered pulp concentration sensor possesses excellent sensitivity and outstanding stability, completing the sensing of pulp concentration signals within 40 ms, with a linear fitting degree of 0.99. The effects of surfactants, lignin, calcium carbonate, and their mixtures on sensing sensitivity were examined, with linear fitting degrees remaining above 0.96, indicating that this self-powered sensor has excellent anti-interference capability. The sensing signal remained stable over a runtime of 1000 s, demonstrating the good practical application potential of this self-powered pulp concentration sensor.