3D printing technology, academically known as “additive manufacturing,” is also referred to as additive manufacturing or incremental manufacturing. According to the definition published by the American Society for Testing and Materials (ASTM) 3D Printing Technical Committee (F42 Committee) established in 2009, 3D printing is a method that contrasts sharply with traditional material processing methods, based on three-dimensional CAD model data, and manufactured by adding materials layer by layer. It employs a manufacturing method that directly creates three-dimensional physical entity models that are completely consistent with the corresponding mathematical models. The content of 3D printing technology encompasses all printing processes, technologies, equipment categories, and applications related to “rapid prototyping” at the front end of the product lifecycle and “rapid manufacturing” throughout the entire production cycle. 3D printing involves the integration of various disciplines including CAD modeling, measurement, interface software, numerical control, precision machinery, lasers, and materials.

In April 2012, the renowned British magazine The Economist published a special report indicating that the global industry is undergoing a third industrial revolution. Unlike previous revolutions, this revolution will have a significant impact on the development of manufacturing, with one representative technology being 3D printing. Time magazine in the U.S. also listed 3D printing as one of the “Top Ten Fastest Growing Industries” in the U.S. Since 2013, there has been a surge of interest in 3D printing technology among domestic media, academia, and the financial sector, with various government departments beginning to focus on and formulate development plans for 3D printing technology.

Compared to traditional printing methods, 3D printing has the following characteristics and advantages: 1. Digital Manufacturing: Digitizes product structures using software such as CAD. Drives machinery to manufacture components; Digital files can also be transmitted over the network, achieving a decentralized manufacturing production model. 2. Layered Manufacturing: This means decomposing three-dimensional structures into two-dimensional layered structures, accumulating layer by layer to form three-dimensional objects. Therefore, in principle, 3D printing technology can manufacture any complex structure, and the manufacturing process is more flexible. 3. Stacked Manufacturing: The “bottom-up” stacking method is more advantageous for achieving heterogeneous materials and functionally graded components.

4. Direct Manufacturing: Any high-performance, difficult-to-form components can be directly manufactured in one go through the “printing” method, without the need for complex processes such as assembly and splicing. 5. Rapid Manufacturing: The 3D printing manufacturing process is short, fully automated, and can achieve on-site manufacturing, thus making manufacturing faster and more efficient.

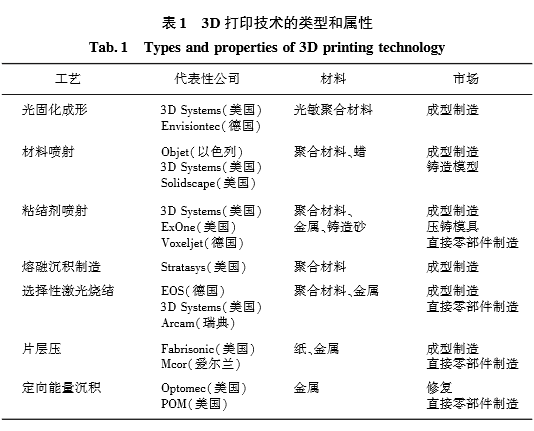

3D printing can be classified by materials into bulk materials, liquid materials, and powder materials, etc. According to the standards of the ASTM F42 Committee, there are currently seven types of 3D printing processes and materials as shown in the table.

Currently, commercialized 3D printers cover seven types of processes, mainly including SLA, SLS, FDM, and 3D printing. Below we will briefly introduce these printing methods.

Stereolithography (SLA)

Stereolithography (SLA) uses ultraviolet light to scan the surface of liquid photosensitive resin, generating a thin layer of a certain thickness each time, and creating the object layer by layer from the bottom up. Its advantages include nearly 100% material utilization, high dimensional accuracy (±0.1mm), excellent surface quality, and the ability to create structurally complex models; however, its drawbacks include high costs, limited available material types, and products that may gradually disintegrate under light exposure.

Manufacturing Process:

1. Ultraviolet Laser Source

2. Photopolymerization Reaction

3. Layer-by-Layer Scanning and Shaping

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) utilizes high-power lasers to heat and sinter powder together to form parts. The advantages of the SLS process include the ability to print metal materials and various thermoplastics, such as nylon, polycarbonate, polyacrylate, polystyrene, polyvinyl chloride, and high-density polyethylene, without the need for supports. The printed parts have good mechanical properties and high strength; however, the disadvantages are that the powder material is relatively loose, the sintered parts have low forming accuracy, and high-power lasers are expensive. SLS is typically used for 3D printing of polymer materials, but can also be used to manufacture metal or ceramic parts, although the resulting parts have low density and require post-processing densification before use.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) uses a heated nozzle to melt plastic filament material, which is then extruded from the nozzle and deposited at specified locations to solidify. This process is similar to the way “toothpaste is squeezed out,” with advantages including low cost, small size, and relatively easy operation; however, the drawbacks include visible stripes on the surface of formed parts, low inter-layer bonding strength, and slow printing speed. FDM is the simplest and most common 3D printing technology, typically used in desktop 3D printing devices.

Manufacturing Process:

1. Model Processing

2. Material Extrusion Forming

3. Layered Printing

4. Support Removal

5. Surface Treatment

3D Printing (3DP)

3D printing (Three-Dimensional Printing) operates similarly to an inkjet printer’s nozzle. This process is very similar to selective laser sintering, except that the laser sintering process is replaced by a binder jetting head. Its advantages include fast printing speed and low cost; however, the drawback is that the mechanical strength of the printed products is not high. The 3DP technology currently has two main applications: full-color 3D printing and sand mold casting.

Manufacturing Process:

1. Binder Jetting

2. Heating and Curing

3. Printing and Forming

4. Casting and Forming

In addition, there are many other printing methods such as:

· CIP (Continuous Liquid Interface Production)

· LMD (Laser Metal Deposition)

· EBM (Electron Beam Melting) technology, etc.