01

Basic Points for PCB Layout of Switching Power Supplies

l.1 High-Frequency Filtering Characteristics of Capacitors

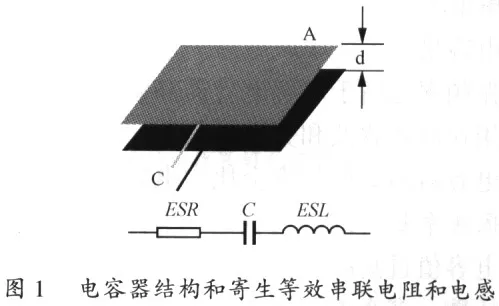

Figure 1 shows the basic structure and high-frequency equivalent model of a capacitor.

The basic formula for a capacitor is

Equation (1) shows that reducing the distance (d) between the capacitor plates and increasing the plate area (A) will increase the capacitance of the capacitor.

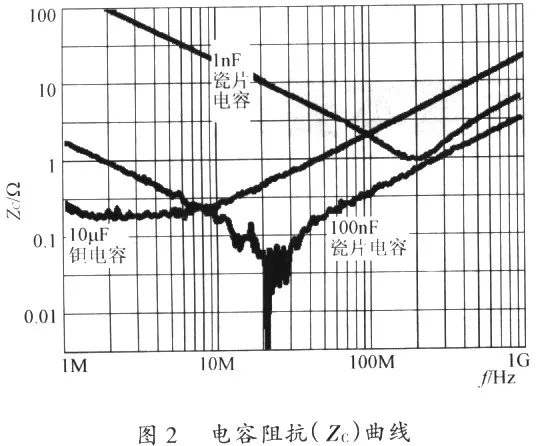

Capacitors usually have two parasitic parameters: equivalent series resistance (ESR) and equivalent series inductance (ESL). Figure 2 shows the impedance (Zc) of a capacitor at different operating frequencies.

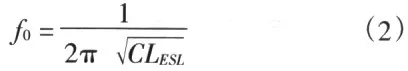

The resonant frequency (fo) of a capacitor can be obtained from its capacitance (C) and equivalent series inductance (LESL), that is

When a capacitor operates at frequencies below fo, its impedance decreases as the frequency increases, that is

When the operating frequency of the capacitor is above fo, its impedance increases as the frequency increases, that is

When the operating frequency of the capacitor approaches fo, the capacitive impedance equals its equivalent series resistance (RESR).

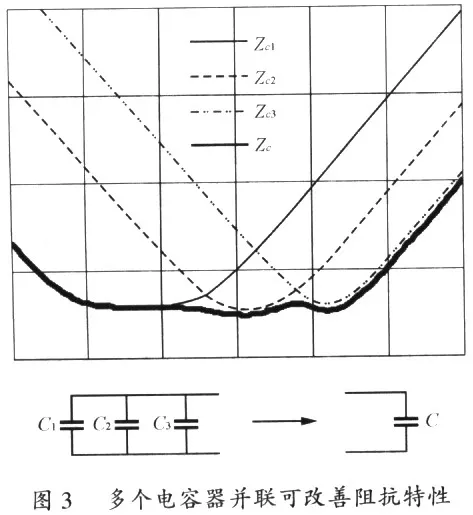

Electrolytic capacitors generally have high capacitance and significant equivalent series inductance. Because their resonant frequency is low, they can only be used for low-frequency filtering. Tantalum capacitors usually have larger capacitance and smaller equivalent series inductance, so their resonant frequency is higher than that of electrolytic capacitors, allowing them to be used for medium to high-frequency filtering. Ceramic capacitors typically have small capacitance and equivalent series inductance, resulting in a resonant frequency that is much higher than that of electrolytic and tantalum capacitors, making them suitable for high-frequency filtering and bypass circuits. Because the resonant frequency of small capacitance ceramic capacitors is higher than that of large capacitance ceramic capacitors, when selecting bypass capacitors, one should not choose ceramic capacitors with excessively high capacitance values. To improve the high-frequency characteristics of capacitors, multiple capacitors with different characteristics can be connected in parallel. Figure 3 shows the effect of improved impedance when multiple capacitors with different characteristics are connected in parallel.

Basic Point 1 for Power Supply Layout: The capacitance of bypass ceramic capacitors should not be too large, and their parasitic series inductance should be as small as possible. Connecting multiple capacitors in parallel can improve the high-frequency impedance characteristics of the capacitors.

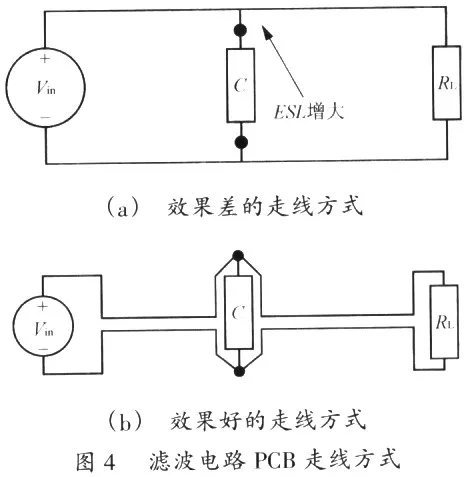

Figure 4 shows different routing methods for input power (Vin) to load (RL) on a PCB. To reduce the ESL of the filter capacitor (C), the lead lengths should be minimized; the routing from Vin positive to RL and from Vin negative to R1 should be as close as possible.

1.2 High-Frequency Filtering Characteristics of Inductors

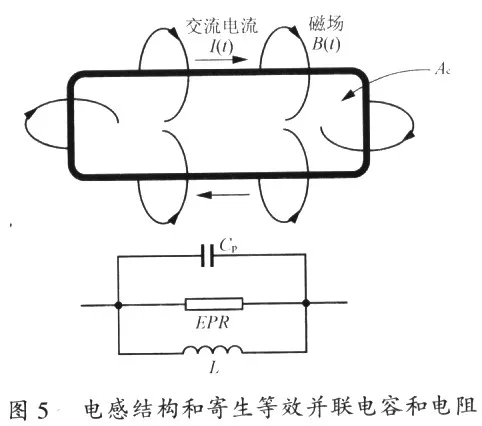

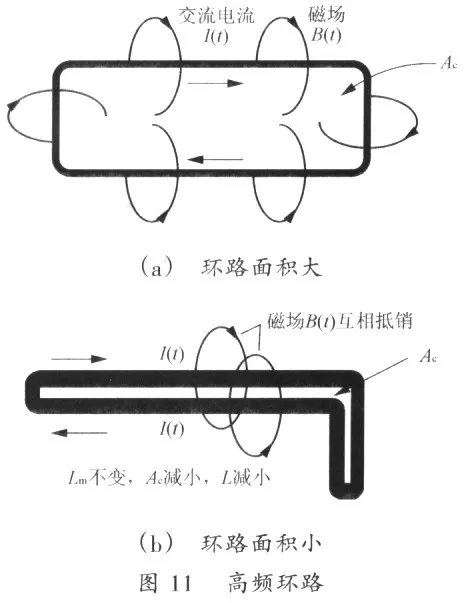

The current loop in Figure 5 is similar to the inductance of a one-turn coil. The electromagnetic field R(t) generated by high-frequency AC current will surround the inside and outside of this loop. If the area of the high-frequency current loop (Ac) is large, it will generate significant electromagnetic interference inside and outside the loop.

The basic formula for inductance is

From equation (5), it can be seen that reducing the area of the loop (Ac) and increasing the loop perimeter (lm) can reduce L.

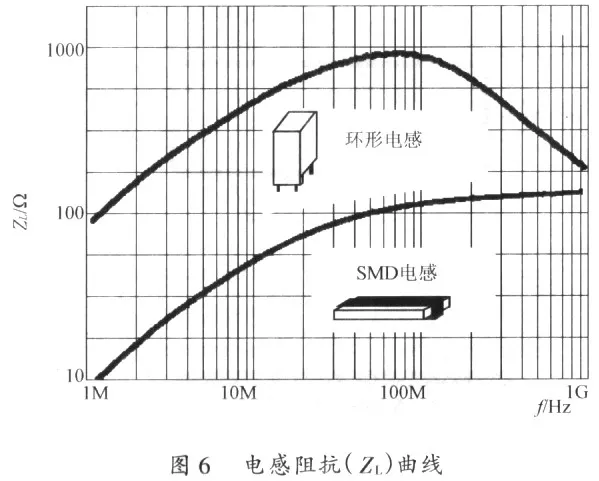

Inductors usually have two parasitic parameters: equivalent parallel resistance (EPR) and equivalent parallel capacitance (Cp). Figure 6 shows the impedance (ZL) of an inductor at different operating frequencies.

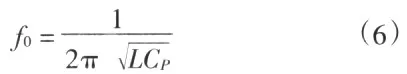

The resonant frequency (fo) can be obtained from the inductance value (L) and its equivalent parallel capacitance (Cp), that is

When an inductor operates at frequencies below fo, its impedance increases as the frequency increases, that is

When the inductor operates at frequencies above fo, its impedance decreases as the frequency increases, that is

When the inductor operates at frequencies close to fo, its impedance equals its equivalent parallel resistance (REPR).

In switching power supplies, the Cp of inductors should be kept as small as possible. At the same time, it must be noted that inductors with the same inductance value can produce different Cp values due to different coil structures. Figure 7 shows the different Cp values of inductors with the same inductance under two different coil structures. Figure 7 (a) shows that a 5-turn winding is wound sequentially. The Cp value of this coil structure is 1/5 of the equivalent parallel capacitance (C) of a one-turn coil. Figure 7 (b) shows that a 5-turn winding is wound in a crossed order, where windings 4 and 5 are placed between windings 1, 2, and 3, and windings 1 and 5 are very close together. The Cp produced by this coil structure is twice the C value of a one-turn coil.

It can be seen that the Cp values of two inductors with the same inductance can differ by several times. If an inductor’s Cp value is too large in high-frequency filtering, high-frequency noise can easily couple directly to the load through Cp. Such an inductor will lose its high-frequency filtering function.

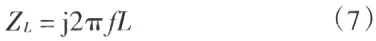

Figure 8 shows different routing methods for Vin through L to load (RL) on a PCB. To reduce the Cp of the inductor, the two pins of the inductor should be kept as far apart as possible. The routing from Vin positive to RL and from Vin negative to RL should be as close as possible.

Basic Point 2 for Power Supply Layout: The parasitic parallel capacitance of inductors should be kept as small as possible, and the distance between the inductor pad soldering points should be as far apart as possible.

1.3 Mirror Plane

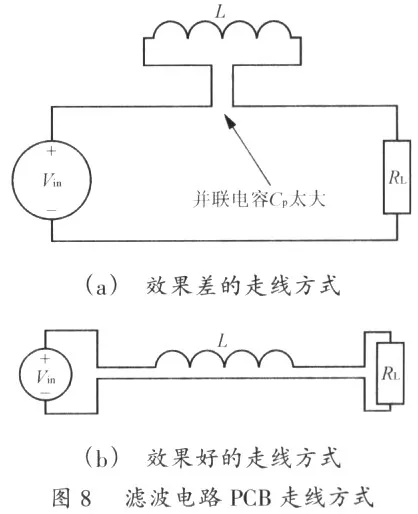

The concept of the mirror plane in electromagnetic theory can greatly assist designers in mastering the PCB layout of switching power supplies. Figure 9 shows the basic concept of the mirror plane.

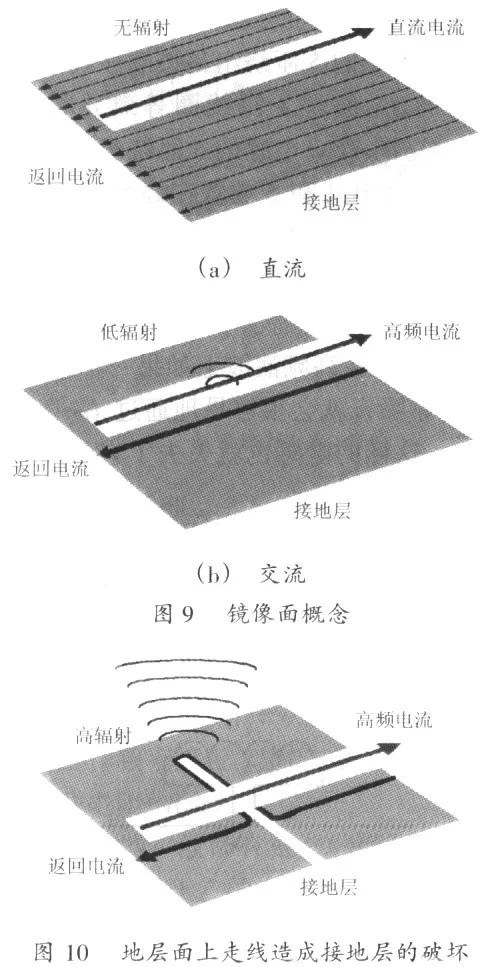

Figure 9 (a) shows the scenario when DC current flows over a ground layer. At this time, the return DC current on the ground layer is very uniformly distributed across the entire ground layer. Figure 9 (b) shows the scenario when high-frequency current flows over the same ground layer. In this case, the return AC current can only flow in the middle of the ground layer, and there is no current on both sides of the ground layer. Once the concept of the mirror plane is understood, it is easy to see the routing issues on the ground layer in Figure 10. Designers should avoid placing any power or signal traces on the ground plane. Once the routing on the ground layer disrupts the entire high-frequency loop, the circuit will generate strong electromagnetic radiation, disrupting the normal operation of surrounding electronic devices.

Basic Point 3 for Power Supply Layout: Avoid placing any power or signal traces on the ground layer.

1.4 High-Frequency Loops

Switching power supplies have many high-frequency loops, and if these loops are not well managed, they can greatly affect the normal operation of the power supply. To reduce the electromagnetic noise generated by high-frequency loops, the area of these loops should be kept very small. As shown in Figure 11 (a), if the area of the high-frequency current loop is large, strong electromagnetic interference will be generated inside and outside the loop. Conversely, when the area of the loop is designed to be very small, as shown in Figure 11 (b), the electromagnetic fields inside and outside the loop will cancel each other, making the entire circuit very quiet.

Basic Point 4 for Power Supply Layout: The area of high-frequency loops should be minimized as much as possible.

1.5 Via and Pad Placement

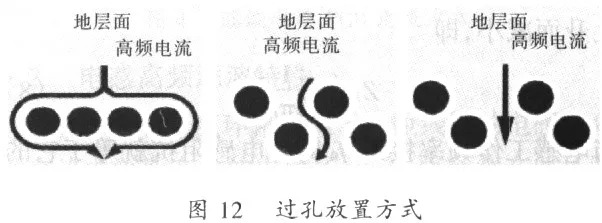

Many designers prefer to place many vias on multilayer PCBs. However, it is essential to avoid placing too many vias on high-frequency current return paths. Otherwise, the high-frequency current routing on the ground layer will be disrupted. If it is necessary to place some vias on high-frequency current paths, space should be left between the vias to allow high-frequency current to flow smoothly. Figure 12 shows the placement of vias.

Basic Point 5 for Power Supply Layout: The placement of vias should not disrupt the flow of high-frequency current on the ground layer.

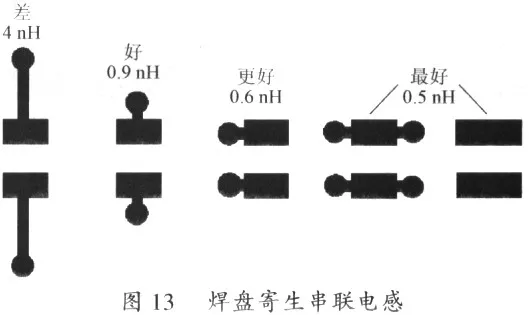

Designers should also note that different pad shapes will produce different series inductance. Figure 13 shows the series inductance values of several pad shapes.

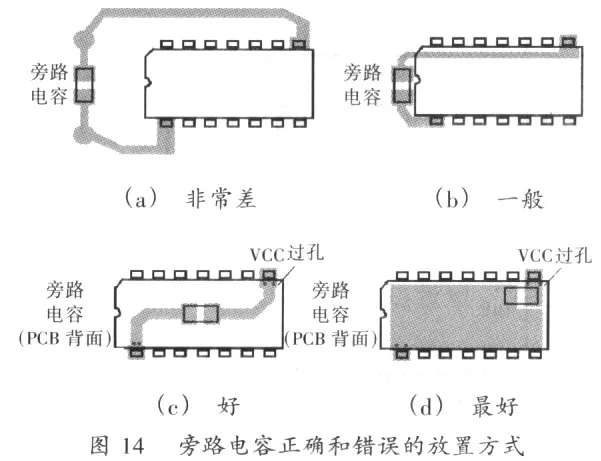

The placement of bypass capacitors (Decouple) should also consider their series inductance values. Bypass capacitors must be low impedance and low ESL ceramic capacitors. However, if a high-quality ceramic capacitor is not placed correctly on the PCB, its high-frequency filtering function will be lost. Figure 14 shows the correct and incorrect placement of bypass capacitors.

1.6 DC Output of Power Supply

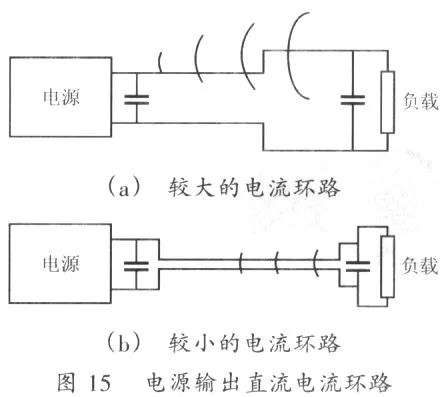

Many switching power supply loads are far from the output port of the power supply. To avoid the output routing being affected by the electromagnetic interference generated by the power supply itself or surrounding electronic devices, the output power routing must be kept very close, as shown in Figure 15 (b), to minimize the area of the output current loop.

l.7 Ground Layer Separation on System Board

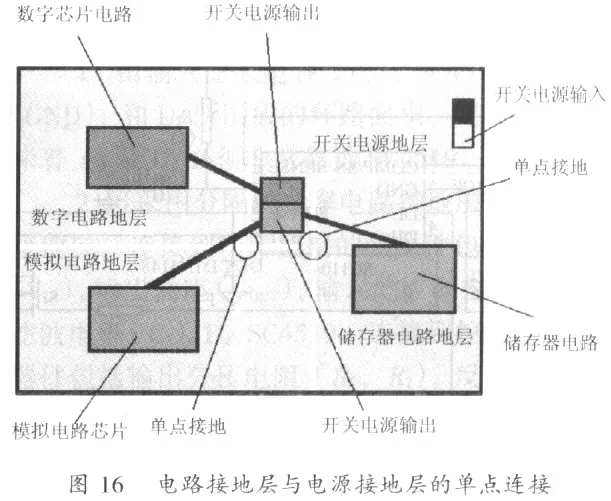

The new generation of electronic product system boards will often have analog circuits and switching power supply circuits simultaneously. To reduce the impact of switching power supply noise on sensitive analog and digital circuits, it is usually necessary to separate the ground layers of different circuits. If multilayer PCBs are used, the ground layers of different circuits can be separated by different PCB layers. If the entire product has only one ground layer, separation must be done within that single layer as shown in Figure 16. Whether separating the ground layers on multilayer PCBs or within a single-layer PCB, the ground layers of different circuits should be connected to the ground layer of the switching power supply at a single point.

Basic Point 6 for Power Supply Layout: Different circuits on the system board require different ground layers, and the ground layers of different circuits are connected to the power ground layer at a single point.

02

Examples of PCB Layout for Switching Power Supplies

The schematic diagram of a pressure-type switching power supply. Designers should be able to distinguish between components in the power circuit and control signal circuit on this schematic. If the designer treats all components in this power supply as components in a digital circuit, the problems will be quite serious. It is usually necessary to first understand the path of high-frequency current in the power supply and distinguish between small signal control circuit components and power circuit components and their routing. Generally speaking, the power circuit of the supply mainly includes input filter capacitors, output filter capacitors, filter inductors, and upper and lower power MOSFETs. The control circuit mainly includes PWM, bypass capacitors, bootstrap circuits, feedback voltage divider resistors, and feedback compensation circuits.

2.l PCB Layout of Power Circuit for Power Supply

The correct placement and routing of power components on the PCB will determine whether the power supply operates normally. Designers must first have a certain understanding of the voltage and current waveforms on the power components of the switching power supply.

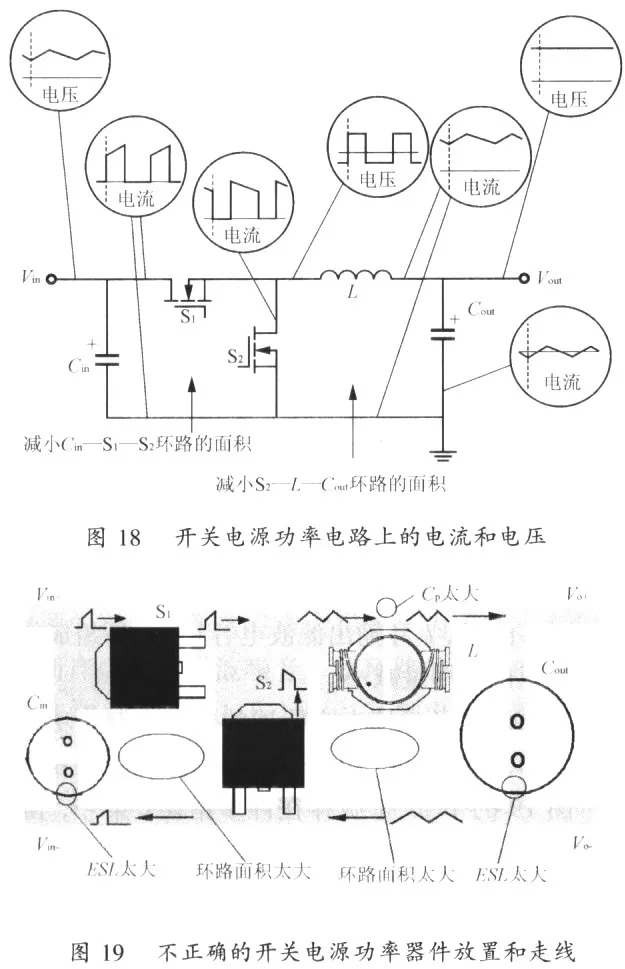

Figure 18 shows the current and voltage waveforms of the power circuit components in a buck-type switching power supply. Since the current flowing through the input filter capacitor (Cin), upper MOSFET (S1), and lower MOSFET (S2) contains high-frequency and high-peak AC current, the loop area formed by Cin-S1-S2 should be minimized. Similarly, the loop area formed by S2, L, and output filter capacitor (Cout) should also be minimized.

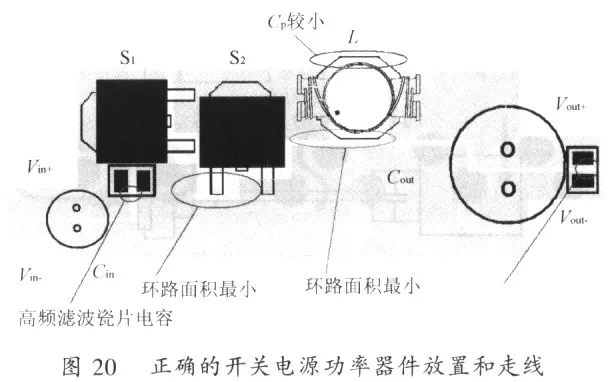

If the designer does not follow the points mentioned in this article to create the power circuit PCB, it is likely to create the PCB shown in Figure 19, which has many errors: First, due to Cin having a large ESL, the high-frequency filtering capability of Cin is almost lost; Second, the areas of the Cin-S1-S2 and S1-L-Cout loops are too large, generating electromagnetic noise that will greatly interfere with the power supply itself and surrounding circuits; Third, the pads of L are too close, resulting in a large Cp that reduces its high-frequency filtering function; Fourth, the lead length of Cout pads is too long, resulting in a large ESL that loses high-frequency filtering capability. The areas of the Cin-S1-S2 and S2-L-Cout loops must be controlled to a minimum. The connection point between the source of S1, the drain of S2, and L must be a solid copper pad. Since the voltage at this connection point is high-frequency, S1, S2, and L need to be very close together. Although there are no high-peak high-frequency currents in the routing between L and Cout, wider routing can reduce DC impedance losses, improving the efficiency of the power supply. If the cost allows, the power supply can use a double-sided PCB with one side completely as a ground layer, but care must be taken to avoid routing power and signal lines on the ground layer. Additionally, a ceramic capacitor is added at both the input and output ports to improve the power supply’s high-frequency filtering performance.

2.2 PCB Layout of Control Circuit for Power Supply

The PCB layout of the power supply control circuit is also very important. An unreasonable layout can cause drift and oscillation of the output voltage of the power supply. The control line should be placed at the edge of the power circuit and must not be placed in the middle of the high-frequency AC loop. Bypass capacitors should be as close as possible to the chip’s Vcc and ground pins (GND). The feedback voltage divider resistors should also be placed near the chip. The loop from the chip driving to the MOSFET should also be minimized.

Basic Point 7 for Power Supply Layout: The loop from the control chip to the upper and lower MOSFETs should be kept as short as possible.

2.3 PCB Layout Example 1 for Switching Power Supply

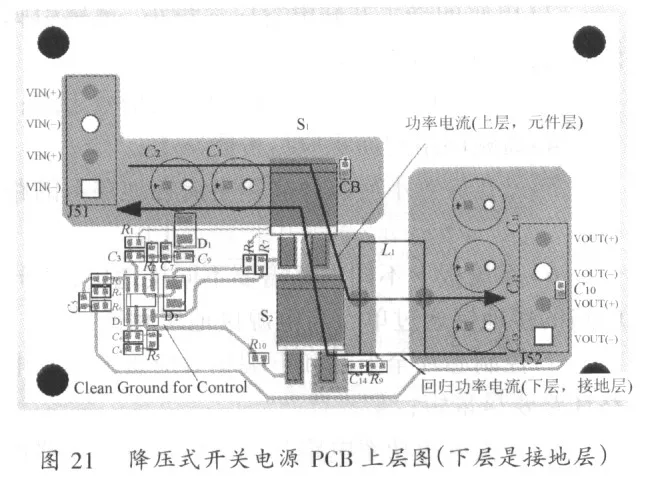

Figure 21 shows the component side routing diagram of the PCB in Figure 17. This power supply uses a low-cost PWM controller (Semtech model SC1104A). The bottom layer of the PCB is a complete ground layer. There is no separation between the power ground layer and the control ground layer. It can be seen that the power circuit of this supply runs from the input socket (top left of the PCB) through input filter capacitors (C1, C2), S1, S2, L1, output filter capacitors (C10, C11, C12, C13) to the output socket (bottom right of the PCB). The SC1104A is placed at the bottom left of the PCB. Since the current of the power circuit does not pass through the control circuit on the ground layer, there is no need to separate the control circuit ground layer from the power circuit ground layer. If the input socket were placed at the bottom left of the PCB, then the current of the power circuit would directly flow through the control circuit, making separation necessary.

2.4 PCB Layout Example 2 for Switching Power Supply

Figure 22 shows another buck-type switching power supply that can convert a 12V input voltage into a 3.3V output voltage, with an output current of up to 3A. This power supply uses an integrated power controller (Semtech model SC4519). This controller integrates a power MOSFET within the power controller chip. Such a power supply is very simple, especially suitable for applications in portable DVD players, ADSL, set-top boxes, and other consumer electronics.

As with the previous example, the following points should also be noted for this simple switching power supply during PCB layout:

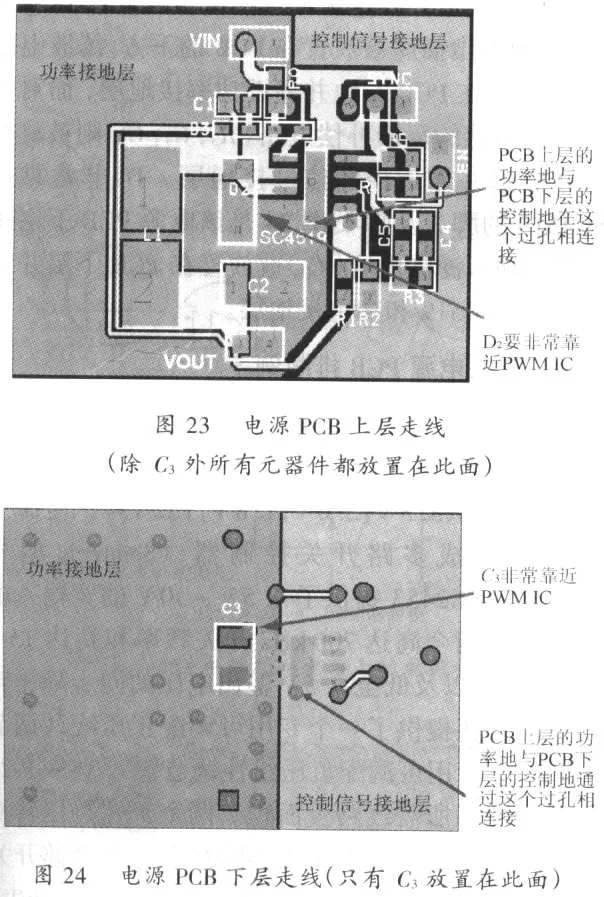

1) The loop area enclosed by the input filter capacitor (C3), the ground pin (GND) of SC4519, and D2 must be small. This means that C3 and D2 must be very close to SC4519.

2) A separated power circuit ground layer and control circuit ground layer can be adopted. Components connected to the power ground layer include the input socket (VIN), output socket (VOUT), input filter capacitor (C3), output filter capacitor (C2), D2, and SC4519. Components connected to the control ground layer include output voltage divider resistors (R1, R2), feedback compensation circuits (R3, C4, C5), enable socket (EN), and synchronization socket (SYNC).

3) A via should be added near the ground pin of SC4519 to connect the power circuit ground layer and control signal circuit ground layer at a single point.

Figure 23 is the routing diagram of the upper layer of this power supply PCB. To help readers understand, the power ground layer and control signal ground layer are represented in different colors. Here, the input socket is placed on the top of the PCB, while the output socket is placed at the bottom of the PCB. The filter inductor (L1) is placed on the left side of the PCB, close to the power ground layer, while the feedback compensation circuit (R3, C4, C5), which is sensitive to noise, is placed on the right side of the PCB, close to the control signal ground layer. D2 is placed very close to pins 3 and 4 of SC4519. Figure 24 is the routing diagram of the lower layer of this power supply PCB. The input filter capacitor (C3) is placed on the lower layer of the PCB and is very close to SC4519 and the power ground layer.

2.5 PCB Layout Example 3 for Switching Power Supply

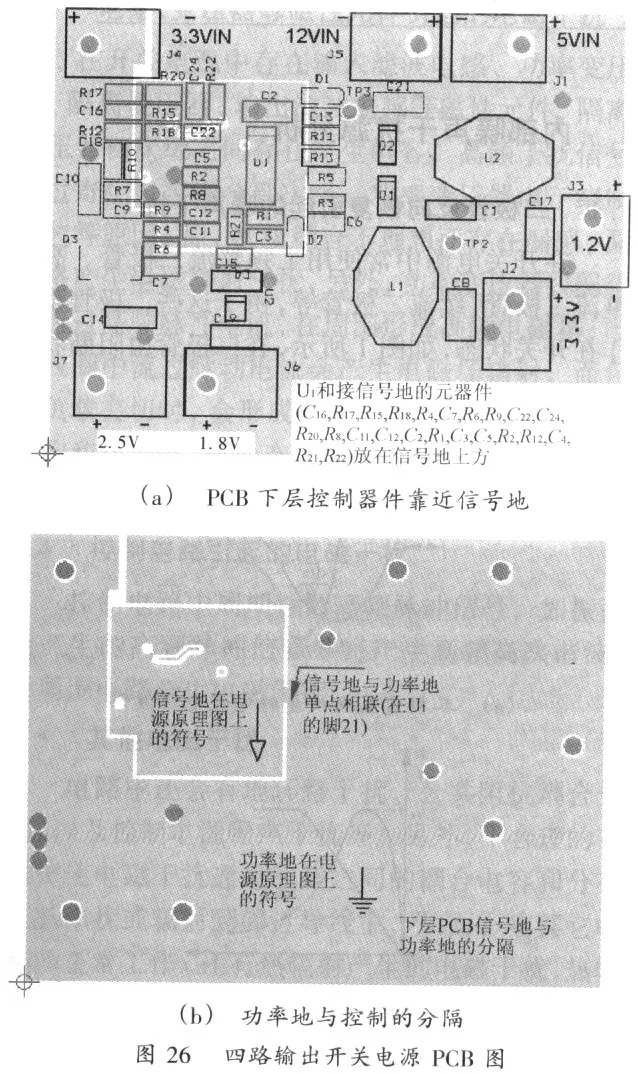

Finally, let’s discuss the key points for PCB layout of a multi-output switching power supply. This power supply has three input voltages (12V, 5V, and 3.3V) and four output voltages (3.3V, 2.6V, 1.8V, and 1.2V). This power supply uses an integrated multi-channel switch controller (Serotech model SC2453). SC2453 provides a wide input voltage range of 4.5V to 30V, switching frequencies of up to 700kHz, and output currents of up to 15A, with output voltages as low as 0.5V. The TSSOP-28 package reduces the required PCB area. Two asynchronous buck converters can reduce input current ripple. Figure 25 is the schematic diagram of this multi-channel switching power supply, where the 3.3V output is generated from the 5V input, the 1.2V output is generated from the 12V input, and the 2.6V and 1.8V outputs are generated from the 3.3V input. Since all components of this power supply must be placed on a small PCB area, the power ground layer and control signal ground layer must be separated. Following the points discussed in previous sections, first distinguish between components connected to the power ground layer and those connected to the control signal ground layer, then place the control signal components on the signal ground layer and near the control signal ground layer of SC2453, connecting the two ground layers at a single point. This connection point is usually chosen at pin 21 of SC2453.

Basic Point 8 for Power Supply Layout: The components of the switching power supply power circuit and control signal circuit need to connect to different ground layers, and these two ground layers are generally connected through a single point.

03

Conclusion

The 8 key points for PCB layout of switching power supplies:

1) The capacitance of bypass ceramic capacitors should not be too large, and their parasitic series inductance should be as small as possible. Connecting multiple capacitors in parallel can improve the impedance characteristics of the capacitors;

2) The parasitic parallel capacitance of inductors should be kept as small as possible, and the distance between inductor pad soldering points should be as far apart as possible;

3) Avoid placing any power or signal traces on the ground layer;

4) The area of high-frequency loops should be minimized as much as possible;

5) The placement of vias should not disrupt the path of high-frequency current on the ground layer;

6) Different circuits on the system board require different ground layers, and the ground layers of different circuits are connected to the power ground layer at a single point;

7) The loop from the control chip to the upper and lower MOSFETs should be kept as short as possible;

8) The components of the switching power supply power circuit and control signal circuit need to connect to different ground layers, and these two ground layers are generally connected through a single point.

Disclaimer: This article is copyrighted by the original author and does not represent the views of the association. The articles promoted by the “Jiangxi Province Electronic Circuit Industry Association” are for sharing purposes only and do not represent the position of this account. If there are copyright issues, please contact us for deletion.