The Fourth Industrial Revolution has spurred the rise of cutting-edge technologies such as cloud computing, big data, 3D printing, artificial intelligence, and virtual reality. These emerging technologies have not only disrupted traditional production methods but also painted a new blueprint for the future development of the manufacturing industry. In recent years, technologies like 5G, artificial intelligence, and 3D printing have gradually entered the public eye, becoming hot topics in the industry. However, the application of various emerging technologies spawned by the Fourth Industrial Revolution in global manufacturing remains lagging behind. More than 70% of manufacturing enterprises have yet to make significant progress in this field.

During this critical period of transformation and development in the manufacturing industry, enhancing factory operational efficiency, supply chains, and business models, minimizing operational costs, maximizing profits, and strengthening human resource development have become common goals for international manufacturers. However, to achieve these goals, manufacturers not only need to layout their manufacturing strategies but also need to introduce and apply innovative technological achievements from the Fourth Industrial Revolution.

During this critical period of transformation and development in the manufacturing industry, enhancing factory operational efficiency, supply chains, and business models, minimizing operational costs, maximizing profits, and strengthening human resource development have become common goals for international manufacturers. However, to achieve these goals, manufacturers not only need to layout their manufacturing strategies but also need to introduce and apply innovative technological achievements from the Fourth Industrial Revolution.

In recent years, faced with sudden crises, many enterprises have been forced to reassess their manufacturing and management strategies. Some international manufacturers have taken the lead in adopting technologies from the Fourth Industrial Revolution and have played significant roles in industry demonstrations. A few forward-looking manufacturers have achieved large-scale applications of advanced manufacturing technologies, greatly enhancing customer experience by improving the operational efficiency of factories and the entire supply chain. Among the technologies adopted by these international manufacturers, artificial intelligence, 3D printing, and the Industrial Internet of Things (IIoT) are the most notable, rapidly changing the landscape of the manufacturing industry and are expected to evolve into a source of investment for enterprises. Artificial intelligence mimics human thought and behavior through programming machines, making them smarter.

Artificial intelligence technology relies on a large amount of external and internal data, including suppliers, customers, trend forecasting indicators, demographics, and broader economic indicators. Supported by these variable data, manufacturers can respond more effectively to changing market conditions and external disruptions.

Currently, artificial intelligence has been applied in various fields such as agriculture, communications, healthcare, transportation, aviation, and finance. In China, artificial intelligence has entered a new stage of rapid development and has achieved significant accomplishments in many areas. In key technologies, domestic machine translation, autonomous driving, and intelligent robotics are keeping pace with the world’s forefront, while developments in areas like facial recognition and voice recognition have reached world-leading levels. Meanwhile, leveraging the data perception capabilities of IoT and the intelligent computing capabilities from cloud to edge, China’s AI development has made remarkable achievements in smart healthcare, smart cities, smart logistics, smart transportation, and smart environmental protection, gradually penetrating from internet applications into the real economy and people’s livelihoods. For instance, artificial intelligence has been widely applied in automatic optical inspection (AOI) in smartphones. Compared to traditional manual inspections, AOI not only reduces costs for enterprises but also minimizes human errors, greatly ensuring the production quality of products.

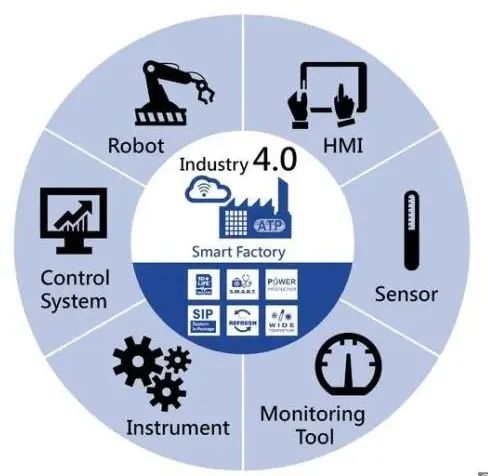

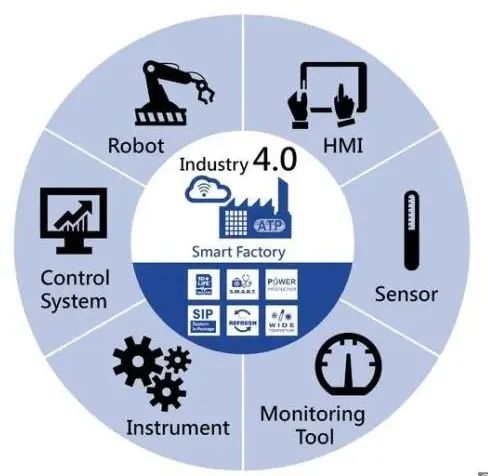

Many of you are likely familiar with the Industrial Internet of Things (IIoT). With the development of new technologies and enhanced technical education, IIoT is no longer confined to specific areas within certain industries but can be widely implemented on production lines. For example, automotive manufacturers can directly monitor inventory, production capacity, and performance testing. Through IIoT, equipment manufacturers can track how many times tools have been used, how parts are allocated, and more.

Currently, the integration of various tools like IIoT with mobile and social initiatives remains the primary goal of enhancing the overall supply chain. It is expected that by 2025, the market size of IIoT will grow from $77.3 billion in 2020 to $110.6 billion. Given this, 73% of manufacturers plan to increase their spending on smart factory technologies in the coming year. Currently, IIoT sensors generate at least 1.44 billion data points per factory every day. The integration of Information Technology (IT) and Operational Technology (OT) is crucial for improving operational efficiency and productivity, accelerating development through digital transformation measures, and promoting long-term talent pool enhancement.

Currently, the integration of various tools like IIoT with mobile and social initiatives remains the primary goal of enhancing the overall supply chain. It is expected that by 2025, the market size of IIoT will grow from $77.3 billion in 2020 to $110.6 billion. Given this, 73% of manufacturers plan to increase their spending on smart factory technologies in the coming year. Currently, IIoT sensors generate at least 1.44 billion data points per factory every day. The integration of Information Technology (IT) and Operational Technology (OT) is crucial for improving operational efficiency and productivity, accelerating development through digital transformation measures, and promoting long-term talent pool enhancement.

Disclaimer: This article is sourced from Sohu.com, we highly respect the copyright of the original author. If there are any copyright issues, please contact the editor of this public account in a timely manner. Thank you!

◆ ◆ ◆ ◆ ◆

● The High-Precision Achievement Transformation and Industrialization Project Undertaken by SuiRui Group Passed Acceptance

● Academician Zhang Jun from the Chinese Academy of Engineering and President of Beijing Institute of Technology Visits SuiRui Technology Group

● SuiRui Showcases Latest Products at the Service Trade Fair, Presenting New Value in Smart Manufacturing

● Dr. Ren Zeping and the Zeping Macro Team Visit SuiRui Group

● Open Sharing, Building the Future Together | SuiRui Joins Hands with the 2022 Open Atom Global Open Source Summit

●SuiRui Recognized as a Top 25 Remote Office, Cloud Office Video Conference Provider by Internet Weekly in 2021!

● Winter Olympics with Me, Communication Without Boundaries! SuiRui Technology Group Delivers a Perfect Conclusion to the Winter Olympics

● SuiRui Technology Group Awarded the Honor of “Outstanding Contribution Member Unit” by the New Infrastructure Construction Committee in 2021

● SuiRui Technology Group and Jiangxi Copper Group Collaborate to Outline a New Blueprint for the Development of “Smart Jiangxi Copper”

About SuiRui Technology Group

SuiRui Technology Group is named “Intelligent World Builder & Operator”, emerging in the industry as a provider of collaborative office software for the Beijing 2022 Winter Olympics and Paralympics, renowned in the government and enterprise markets for many years. SuiRui focuses on communication cloud and artificial intelligence as its core business segments, serving over 700,000 clients in government/enterprise and over 10 million platform service clients, with cumulative coverage of over 100 million end users, providing solutions and supporting services in the field of intelligent world. Currently, the group’s products cover technology innovation fields including cloud computing (including communication cloud and industry management cloud), artificial intelligence, IoT, industrial internet, big data platforms, edge computing, and information security.

Contact Us

Headquarters: No. 1 Baosheng South Road, Haidian District, Beijing, Building 18/19, Aobei Technology Park, Beijing SuiRui Center

Global Customer Hotline: +86 400-010-6066