The application of robots is becoming increasingly widespread, playing an important role in industrial production and efficiency improvement. Industrial robots mainly utilize servo motors for motion control, enabling movement and the grasping of tools. This article will discuss in detail the characteristics of servo motors and the corresponding control principles of different types of servo motors.

Principles of Motion Control

Motion control is closely related to robots. In industrial applications, robots must move independently through actuators composed of multiple motors to perform tasks or grasp tools through robotic arms.

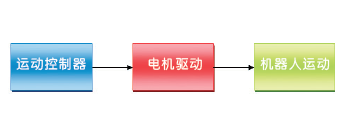

The motion control system of a robot typically consists of a motor controller, motor driver, and the motor itself (mostly servo motors). The motor controller has intelligent computing capabilities and can send commands to drive the motor. The driver provides boosted current to drive the motor according to the controller’s instructions. Motors can move the robot directly or enable movement through a transmission system or chain system.

Figure 1: Motion Control System of a Robot.

Output Types

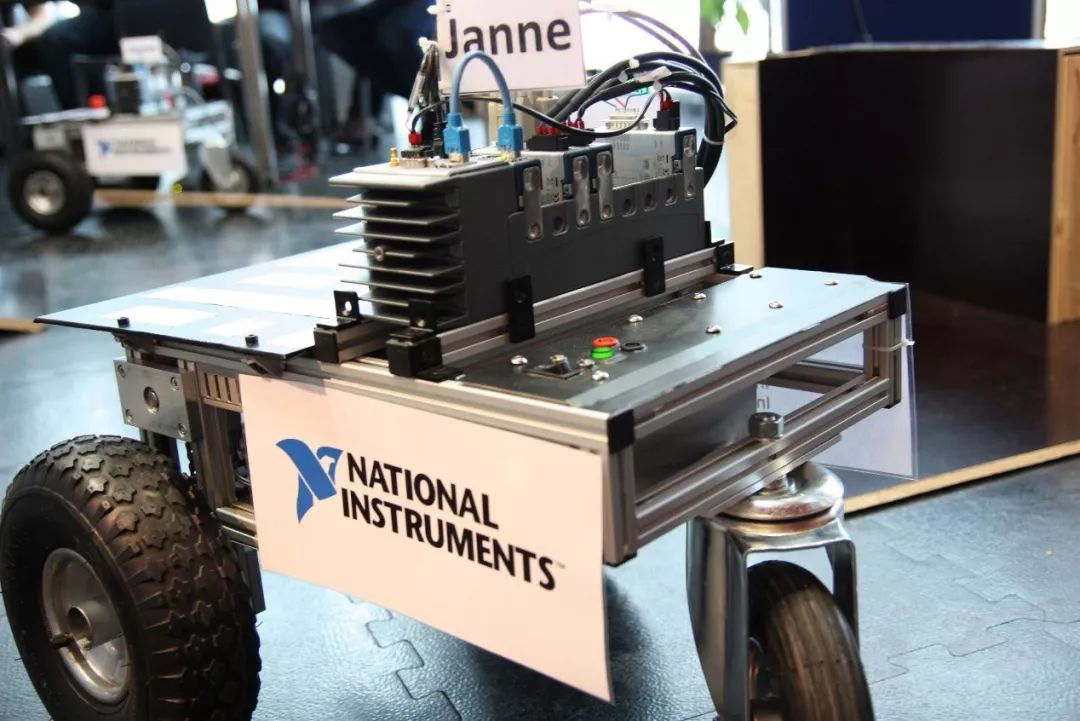

Mobile robots are often used to explore large areas of land and can move using various propellers, mechanical legs, wheels, tracks, or robotic arms. For example, various NI demonstration platforms, including VINI, VolksBot, and Isadora. These robots use omnidirectional wheels (Mecanum wheels), standard wheels, and robotic arms respectively. For embedded control, platforms like NI CompactRIO can be used, integrating real-time controllers and FPGAs. CompactRIO also includes a reconfigurable chassis to accommodate diverse I/O configurations, including sensor inputs and motor control.

VINI is a robot platform that uses omnidirectional wheels, allowing it to move in multiple directions. Besides moving forward and backward like traditional wheels, omnidirectional wheels can also rotate the wheel axis in the opposite direction, enabling movement in any direction. This type of wheel is commonly used in applications like automated stackers that need to operate in confined spaces.

VINI is also a mapping robot that performs path planning and data processing tasks using NI industrial-grade controllers and CompactRIO. The embedded industrial-grade controller provides laser-scanned maps and performs machine vision processing, allowing CompactRIO to receive sensor data and control servo motors on the camera system.

Figure 2: VINI Robot.

Figure 2: VINI Robot.

The wheels used by VolksBot were developed by the Fraunhofer Institute in Germany.

Figure 3: RT3 VolksBot developed by the Fraunhofer Institute.

Figure 3: RT3 VolksBot developed by the Fraunhofer Institute.

Isadora is a dancing humanoid robot that operates based on input data from a scaled-down version of the robot controlled by a human. It then moves its robotic arms and torso to mimic the movements of the scaled-down robot. Isadora uses two sets of CompactRIO, one for simulating recorded movements and the other for allowing the robot to reproduce movement trajectories.

Figure 4: Isadora Dancing Robot.

Control Principles and Types of Servo Motors

Servo motors are a common type of motor used in robotic applications. The basic control principle utilizes a control loop, combined with necessary motor feedback, to assist the motor in achieving the desired state, such as position and speed. Since servo motors must understand their current state through the control loop, they are more stable than stepper motors.

There are different types of servo motors – brushed and brushless. The difference between brushed and brushless servo motors lies in their communication mechanisms. The working principle of a servo motor is based on reverse magnetism to move or establish torque. The simplest examples include fixed magnetic fields and rotating magnetic fields. By changing the direction of the current flowing through the magnetic field, the magnetic poles can be altered, causing the poles (rotor) to start rotating. Changing the current direction in the coils is known as “commutation.”

Brushed Servo Motors

The control principle of a brushed servo motor is to change the current in the motor coils through mechanical brushes. Since brushed motors can change the direction of the incoming current, they can be powered by a direct current (DC) source. Brushed servo motors can be divided into two groups of components:

-

The motor casing has a field magnet, which is the stator.

-

The rotor is composed of coils with a metallic core in the middle, connected to a current converter.

The brushes contact the current converter, directing current into the coils. After a period of use, the brushes may wear out and create friction in the system; however, this does not occur in brushless servo motors.

Brushless Servo Motors

Most brushless servo motors use alternating current (AC) power. The control principle of brushless servo motors is to place the iron core externally. When the rotor becomes a temporary magnet, the stator becomes a coil winding around the iron. The current from the external circuit will reverse at a predetermined rotor position. Therefore, this type of servo motor is driven by alternating current. Of course, there are also brushless DC servo motors. These motors generally have certain electronic switching circuits to convert the incoming DC. Brushless servo motors are more expensive but have fewer wear issues.

Stepper Motors

In robotic motion applications, stepper motors are not as prevalent as servo motors but remain an important example of motors and are easier to use. Compared to servo motors, stepper motors are slower and more precise. Stepper motors have a series of built-in brushless teeth, which, when current flows and changes the electromagnetic charge, pull the rotor with the next set of brush teeth while the previous set pushes the rotor, thereby powering the stepper motor.

Compared to servo motors, stepper motors can achieve precise control through the number of brush teeth (equal to the distance moved) and generally do not require feedback. However, they may miss brush teeth due to obstacles, so encoders can be used as feedback.

Motion Controllers and Software Architecture

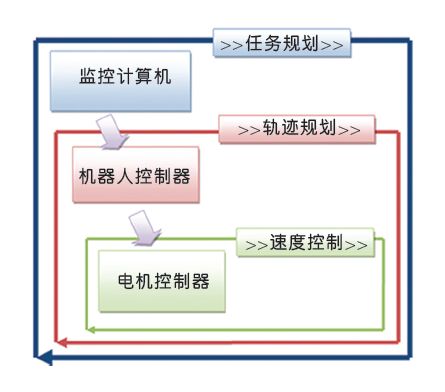

Many manufacturers have established their own drive systems to control robots. When considering the motion control system in robotic applications, one can first understand the basic mesh loop, as shown in the figure below.

Figure 5: Motion Control Software Architecture.

As for the higher-level functions of robotic task planning, they aim to achieve the robot’s actions toward the final goal. It may encompass multiple objectives in a single command or allow the robot to reach a specific location. If the robot adopts a tele-operated architecture, these commands are most likely transmitted through an off-board computer, where human operators can select the robot’s subsequent actions or behaviors. In fully automated robots, task planning may also be executed directly on-board, depending on the decision-making algorithms used.

When planning a path, questions like “How should I get to the destination to complete this task?” or “How should I move the robotic arm to that position?” often arise. Such questions can be addressed by the robot’s motion controller.

Once the destination and speed are clear, the servo motor controller will send control signals (PWM or current, etc.) to the actual motor driver, enabling it to reach the destination. Generally, the control functionality is constructed using PID. It is also important to establish safety features at this time. For example, if a robot moving at high speed detects a human on its current path, it should send an emergency signal to stop the motor or brake immediately.

Business Cooperation: 010—88379790 ext 802

Disclaimer: This article is a network reprint, and the copyright belongs to the original author. However, due to the numerous reprints, it is impossible to confirm the true original author, so only the source of reprint is indicated. If any videos, images, or text used in this article involve copyright issues, please inform us immediately, and we will confirm the copyright based on the proof you provide and pay remuneration according to national standards or delete the content immediately! The content of this article represents the views of the original author and does not represent the views of this public account or its authenticity.