Although 3D printing technology provides the possibility of manufacturing complex shapes,ensuring the continuity and uniformity of fibers, as well as avoiding excessive defects in complex structures, remains a challenge.

Continuous fiber 3D printed honeycomb structure

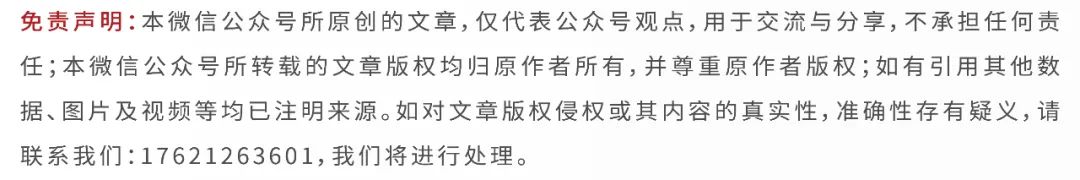

Honeycomb sandwich structures are favored in aerospace, automotive, rail transportation, and related industries due to their lightweight, high specific strength, high specific stiffness, and excellent energy absorption characteristics. This structure mainly consists of two panels and a lightweight honeycomb core, where the panels bear bending and in-plane loads, while the honeycomb core is firmly attached to the panels to withstand transverse shear loads.

The traditional method of constructing honeycomb sandwich structures involves the separate manufacturing of panels and core materials, which are then bonded together using adhesives. However, this method is complex and limited by the forming molds, requiring completion under high temperature and pressure conditions, leading to a complicated and costly production process. Therefore, innovative manufacturing processes are particularly important for achieving cost-effective production of honeycomb sandwich structures.

Traditional honeycomb sandwich structures require separate manufacturing of panels and core materials and bonding them together

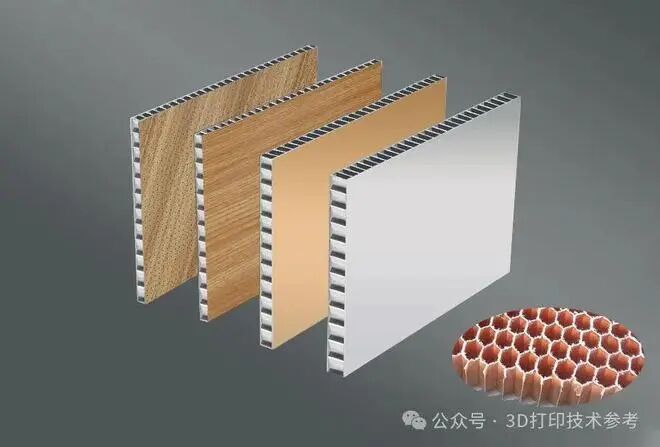

Fused Filament Fabrication (FFF) technology is one of the most popular 3D printing technologies today. Its advantages include a simple process, cost-effectiveness, a wide variety of material choices, high material utilization, and the ability to quickly manufacture complex-shaped parts without molds. This technology is expected to break through the limitations of traditional manufacturing methods, enabling efficient and low-cost production of complex structures. In 3D structure manufacturing, thermoplastic filament and its composites are the main materials. Compared to short fiber reinforced composites and pure thermoplastics, continuous carbon fiber reinforced composites exhibit superior strength and performance. Therefore, in recent years, the 3D printing technology of continuous carbon fiber composites has received significant attention, not only in scientific research but also in successful commercial applications. These efforts have greatly promoted the practical application of fiber reinforced composite 3D printing technology in engineering, showcasing its broad development prospects.

Markforged continuous fiber 3D printing enhancement process

However, FFF technology 3D printing of continuous fiber composites may still produce printing defects, such as fiber bundle direction deviation from the resin matrix, fiber pull-out at path corners, and pure resin matrix areas formed when changing the printing path direction (e.g., 180° turns). These defects can adversely affect the mechanical properties of the final product. To achieve ideal mechanical performance, careful consideration and optimization of printing parameters and structural design are required. 3D printing technology references note that,

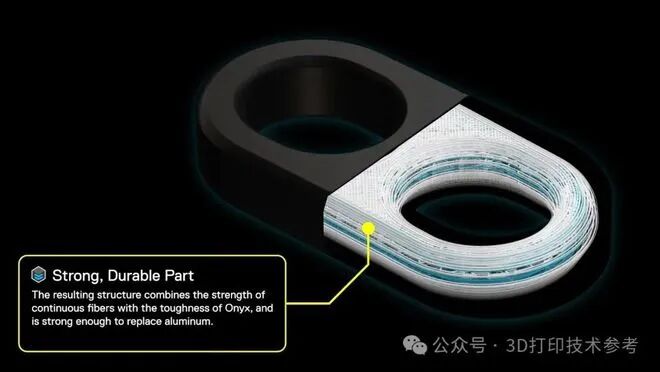

The team led by Fu Rao at Dalian University of Technology recently published an article titled “Enhancing planar compression performance of 3D printed continuous carbon fiber reinforced honeycomb sandwich structures using interleaved core paths” in the Journal of Manufacturing Processes.

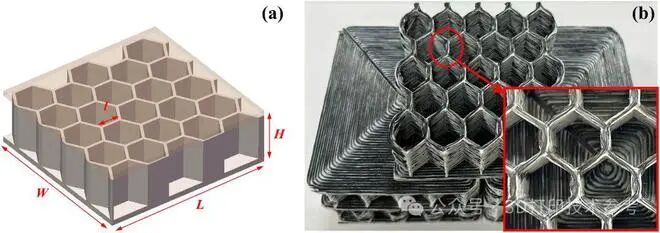

(a) Honeycomb sandwich structure model and (b) printed components of the honeycomb sandwich structure

To enhance the 3D printing quality between honeycomb core units, researchers introduced a novel printing path design strategy called“interleaved core alignment printing method”,aimed at improving the bonding effect within the core units. This strategy considers challenges such asinsufficient bonding and fiber deposition deviation encountered when 3D printing honeycomb structures with continuous fibers. The design involves aligning and offsetting the printing paths between core units to enhance the structural integrity of 3D printed continuous fiber reinforced honeycomb structures. The researchers employed both the proposed and original path planning strategies to manufacture honeycomb sandwich structures with different core sizes. Through in-plane compression tests and microscopic observations, the mechanical properties and damage modes of these structures were thoroughly studied and compared. Additionally, in-depth analysis and discussion were conducted to understand the impact of structural parameters within the honeycomb core on the mechanical properties of the sandwich structure.

(a) Schematic diagram of symmetric honeycomb core printing path planning strategy; (b) Schematic diagram of interleaved honeycomb core printing path planning strategy; (c) Contact state of symmetric path; (d) Fiber misalignment at corner features; (e) Contact state of interleaved path

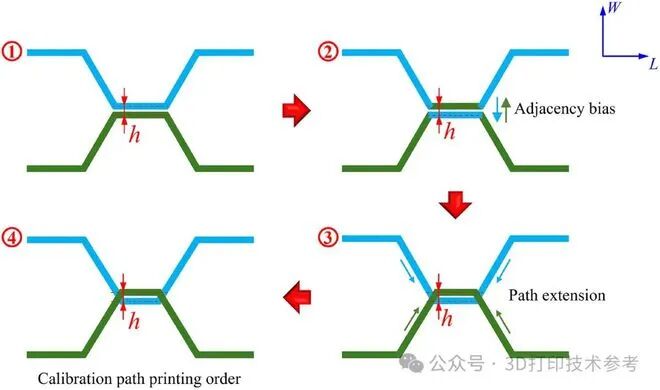

Process of planning interleaved alignment printing paths

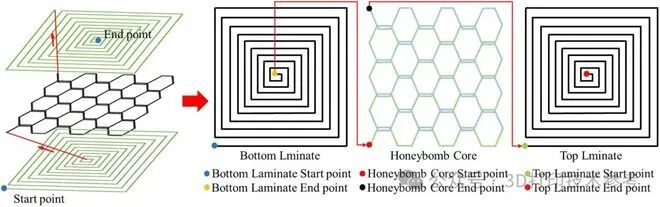

Printing path design scheme for honeycomb sandwich structures

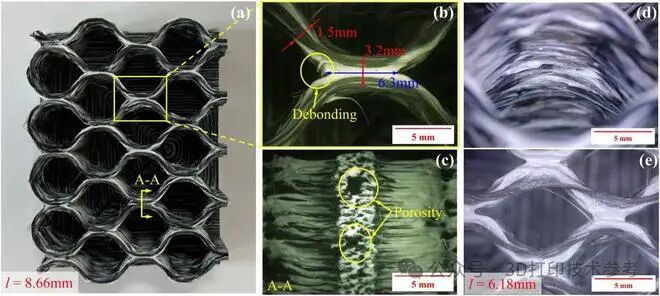

Comparing different shapes of honeycomb core structures, it was found that using interleaved path printing significantly improved the forming quality of the core. When the edge length of the honeycomb core was 8.66 mm, the effective bonding length between units increased by approximately 30%. Even with increased honeycomb core density and reduced core edge length, good bonding quality between units could still be maintained.

Compared to honeycomb sandwich structures printed using symmetric paths, those printed with interleaved paths exhibited significant improvements in planar compression performance. As the size of the honeycomb core decreased, this performance enhancement became more pronounced, with compressive strength increasing from 96% to 167%, compressive modulus ranging from 67.5% to 116%, and specific strength increasing from 125% to 165%.

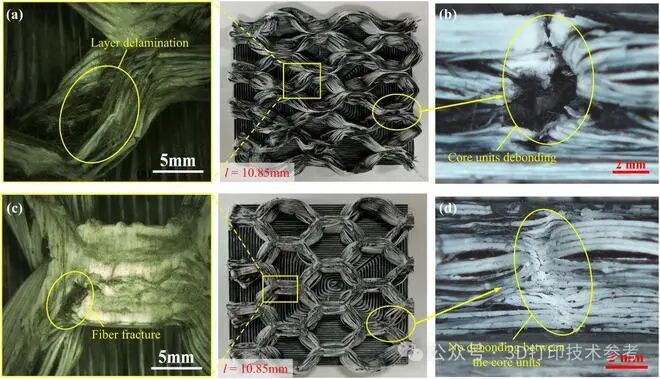

The failure modes of the honeycomb core indicate that the bonding quality between units has a significant impact on the mechanical properties of the sandwich structure. Excellent bonding quality between honeycomb core units can prevent delamination damage propagation, ensuring structural stability and enhancing the mechanical performance of honeycomb sandwich components. The comparison results of specific strength further demonstrate that maintaining the integrity and stability of the honeycomb structure is crucial for enhancing structural performance.

Analysis of the morphology of honeycomb core structures printed with symmetric paths: (a) Honeycomb core structure; (b) Delamination between core units; (c) Interstitial voids; (d) Fiber pull-out; (e) Exacerbated fiber pull-out

Failure modes of the honeycomb core: (a) Honeycomb core printed with symmetric paths; (b) Side view of delamination between core units; (c) Honeycomb core printed with interleaved paths; (d) Side view of good bonding quality between core units

Overall, this research provides valuable references for the 3D printing of high-performance sandwich structures using continuous fiber reinforced thermoplastic composites. The results indicate that optimizing the forming path, improving the bonding quality between core units, and ensuring the stability of unit structures are crucial for enhancing the structural integrity of 3D printed continuous fiber reinforced composites. These findings not only deepen our understanding of the composite 3D printing process but also provide important guiding principles for the future design and manufacture of higher performance and more reliable sandwich structures.

END

Source: Material Intelligence, edited and organized by Mai Aide