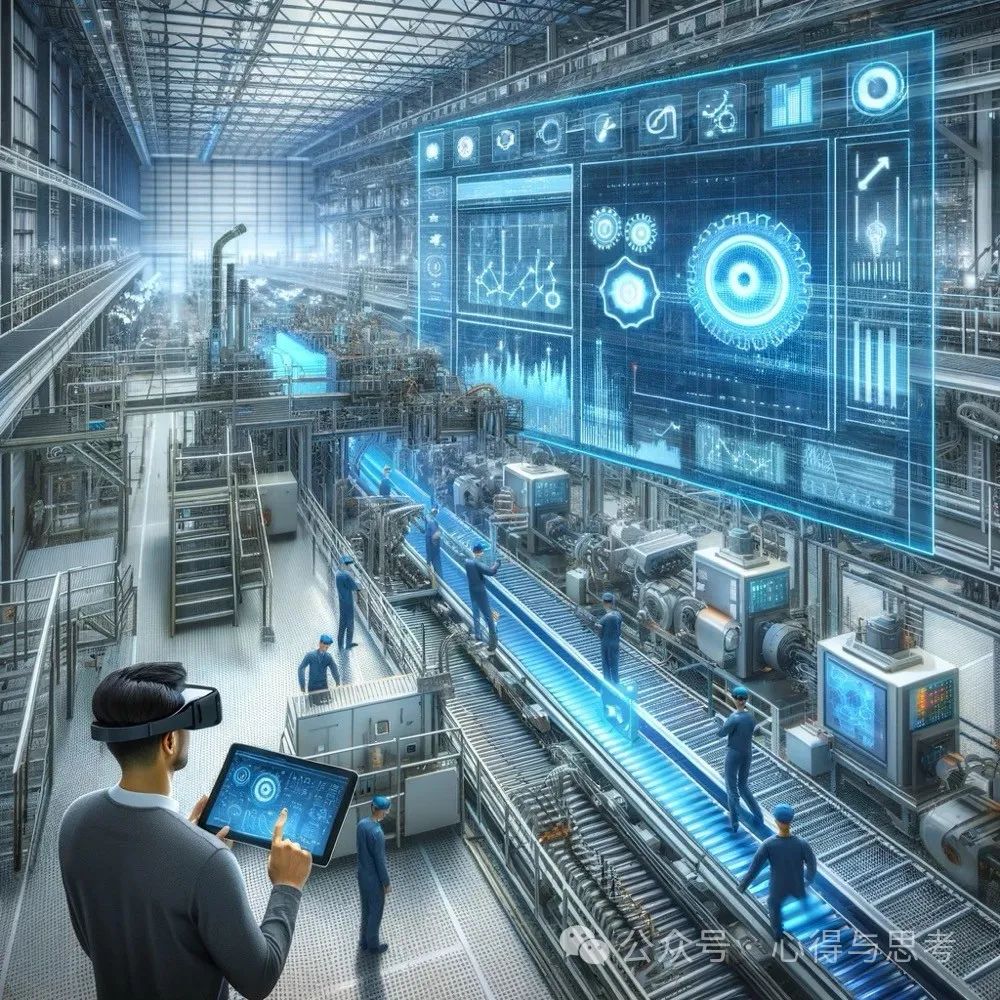

We are in a new trend of Industry 4.0 and smart manufacturing, which is like giving factories a pair of high-tech “wings” to help them fly higher and faster.

Currently, many factories face a headache: what to do with those old PCs and IPCs (Industrial Personal Computers)? They are like a pile of “antiques” sitting by the production line, neither cool nor fast enough.

Of course, it is crucial to take appropriate measures to tackle these challenges. By effectively upgrading and integrating these old devices, we can ensure that the digital transformation of factories is not just a superficial change but a profound and comprehensive advancement. This way, factories can not only improve production efficiency but also gain a competitive edge in a fierce market, ultimately achieving the long-term goal of sustainable development. Therefore, properly handling these devices to align them with modern technology is a key step towards realizing the future of industrial digitization.

1. Current Problems and Their Impacts of Old Equipment

-

Reduced Production Efficiency:

-

Slow processing speed leads to slower production processes.

-

The equipment may not be compatible with new software or production systems, affecting the overall production flow.

Data Security and Reliability Issues:

-

Security vulnerabilities due to lack of the latest security updates make them susceptible to cyberattacks.

-

Risk of data loss increases due to aging hardware, making data more prone to loss or damage.

Increased Maintenance Costs and Difficulties:

-

High repair costs as old equipment requires maintenance more frequently.

-

Parts are hard to obtain, especially for discontinued old equipment.

Impact on Work Environment and Operator Efficiency:

-

Unfriendly user interfaces reduce operator efficiency.

-

Generate more noise and heat, worsening the work environment.

Low Energy Efficiency:

-

Old equipment typically has low energy efficiency, increasing energy consumption.

Limitations on Innovation and Expansion:

-

Technological limitations make it difficult to support emerging technologies like IoT and AI.

-

Restricts innovation and expansion on the production line.

Non-compliance with Modern Standards:

-

May not meet modern environmental and energy-saving standards.

-

Does not satisfy the criteria for modern Industry 4.0 or smart manufacturing.

2. Recommended Transformation Strategies

To address these challenges, it is essential to assess and upgrade these old PCs and IPC devices during the digital transformation. Utilizing modern equipment and technology can not only enhance production efficiency and product quality but also improve data security, reduce maintenance costs, and lay the groundwork for future technological upgrades and innovations. Additionally, updating equipment contributes to creating a more user-friendly and environmentally friendly work environment to meet the sustainable development requirements of modern industry.

When implementing these reforms, companies should consider the following strategies:

-

Conduct a Technical Assessment: Assess the performance of current devices and prioritize upgrades or replacements.

-

Invest in Advanced Technology: Introduce efficient and highly compatible new equipment to enhance automation and intelligence levels.

-

Train Employees: Ensure that employees have sufficient understanding and training on new technologies to effectively utilize these tools.

-

Security and Data Backup: Strengthen cybersecurity measures to ensure data security and backup mechanisms are in place.

-

Continuous Monitoring and Improvement: Regularly evaluate the effectiveness of technology to ensure continuous improvement and updates.

Through these measures, factories can not only better adapt to current digital trends but also prepare for potential market changes, thus maintaining competitiveness in a rapidly evolving industrial environment.

3. Advantages of VMware Technology for Old PCs and IPC Devices

In the wave of industrial digital transformation, VMware, with its advanced technological solutions and deep industry experience, has become an important force in promoting this transformation. The reasons VMware’s solutions can effectively support factory renovations are mainly due to the following advantages:

1. Virtualization Technology (VMware vSphere & VMware Aria Automation)

-

Resource Optimization: By virtualizing servers and desktops, it increases the utilization of existing hardware and reduces the need for physical hardware.

-

Real-time Performance: Supports real-time operating system capabilities, allowing VMware to integrate applications with strict low-latency requirements, such as PLCs and robotic arms, which are crucial for real-time monitoring and control of production lines.

-

Automated Management: Utilizes VMware Aria Automation to achieve automated configuration and management of resources, improving operational efficiency while ensuring system responsiveness.

-

Performance and Reliability Improvement: Provides a high-performance virtual machine environment, increasing system processing speed and reliability while ensuring low-latency data transmission to meet industrial automation needs.

2. VMware Aria Operations (formerly VMware vRealize Operations)

-

Intelligent Alerts and Troubleshooting: Timely identification and response to potential issues, reducing downtime.

-

System Health Visualization: Provides comprehensive visualization of system operational status, helping to quickly diagnose problems.

3. VMware NSX & VMware Aria Network Insight (formerly VMware vRealize Network Insight)

-

Network Security and Micro-segmentation: Achieves network micro-segmentation, enhancing network security.

-

End-to-end Network Visualization: Provides panoramic visualization of the network, helping to understand network traffic and configuration.

4. VMware Edge Compute Stack

-

Edge Computing Support: Reduces latency and improves data processing speed, suitable for applications near the production line.

-

VECO Platform: VMware Edge Compute Stack Orchestrator (VECO) is a management and coordination platform designed for edge computing environments, providing centralized management and automation tools to simplify deployment and operations across multiple edge sites. VECO enables enterprises to efficiently manage their edge computing resources, ensuring quick data processing close to the data source while optimizing resource usage and reducing operational costs.

Other Features of VMware Solutions

1. Flexibility and Scalability

-

Quickly Adapt to Changes: Flexibly adjust resources to support hybrid deployments of private and public clouds.

-

Support for Future Technologies: Easily integrates emerging technologies like IoT and AI.

2. Cost-effectiveness

-

Reduce Overall Costs: Virtualization reduces hardware investment and operating costs.

-

Optimize Operational Costs: Centralized management reduces maintenance and support expenses.

3. High Availability and Disaster Recovery

-

Reduce Downtime Risks: Through high availability solutions and rapid disaster recovery strategies, ensure critical business continuity.

4. Cloud Services and Hybrid Cloud Solutions

-

Cloud Expansion and Flexibility: Flexibly migrate and expand resources between private and public clouds.

-

Data Management and Analysis: Utilize cloud computing for big data analysis and real-time data processing.

In summary, VMware’s comprehensive solutions provide strong support for industrial digital transformation. Looking ahead, as Industry 4.0 continues to develop, we expect VMware’s technology to continue leading innovation, helping more factories achieve their digital transformation goals. Through continuous technological innovation and service optimization, there is potential to lead the industrial sector into a more automated, intelligent, and efficient new era. This will not only greatly enhance capacity and market competitiveness but also promote the sustainable development of the entire industrial ecosystem, bringing a greener and smarter future to global industrial production.