Click the blue text to follow us

In the field of industrial automation, Siemens PLC has become an important tool for optimizing control systems due to its powerful performance and flexible functions. This article will cover the entire process from logical design to debugging, introducing how to use Siemens PLC to improve the efficiency and reliability of industrial control systems.

Logical Design: Laying a Solid Foundation for the Control System

Designing a good PLC program is like building a house; you need to lay a solid foundation first. Before starting programming, we need to prepare the following:

-

Requirement Analysis: Carefully outline the functional requirements of the control system, including input and output signals, control processes, exception handling, etc.

-

System Framework: Divide the entire control system into several functional modules, such as main control, safety monitoring, data acquisition, etc.

-

Variable Planning: Reasonably plan the internal variables of the PLC, including input and output addresses, intermediate variables, data blocks, etc. It is recommended to use meaningful variable names; for instance, “Motor_Start” is easier to understand than “M1.0”.

-

Flowchart Drawing: Use flowcharts to illustrate the control logic, allowing for a visual representation of the entire system’s operation.

Note: Spending more time in the design phase can make subsequent programming and debugging much more efficient.

Program Writing: The Art of Simplifying Complexity

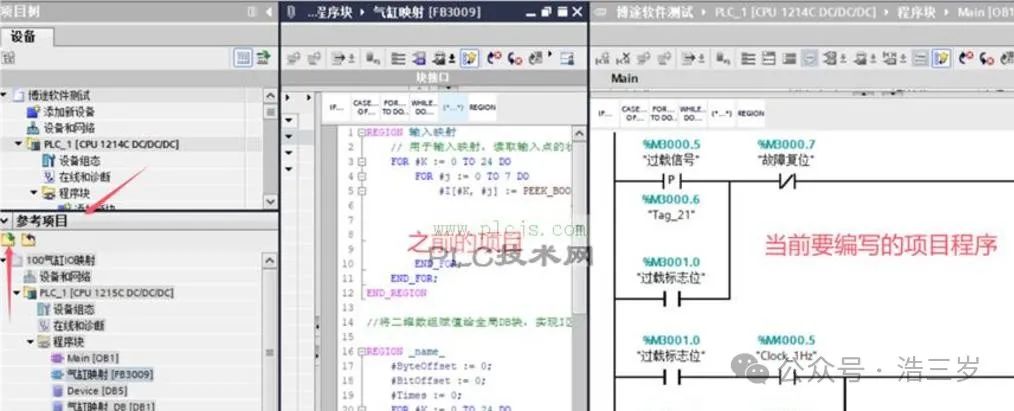

With a clear design approach, the next step is to translate these into a program that the PLC can execute. Siemens PLC supports multiple programming languages, with ladder diagram (LAD) and function block diagram (FBD) being the most commonly used.

-

Modular Programming: Break complex control logic into multiple function blocks (FB), where each function block is responsible for a specific task. This not only facilitates management but also improves code reusability.

-

Standard Instruction Set: Familiarize yourself with and effectively use the standard instruction set of Siemens PLC, such as timers (TON), counters (CTU), etc., which can significantly simplify programming tasks.

-

The Art of Commenting: Appropriate comments can make the program more readable. However, remember that good code itself is the best comment; do not overly rely on comments to explain obscure logic.

-

Data Types: Using data types appropriately can enhance the efficiency and reliability of the program. Use BOOL type for binary values and REAL type for analog values.

Code Example:

// Motor Start Function Block

FUNCTION_BLOCK "Motor_Start"

VAR_INPUT

Start_Button: BOOL; // Start Button

Stop_Button: BOOL; // Stop Button

END_VAR

VAR_OUTPUT

Motor_Run: BOOL; // Motor Running Status

END_VAR

NETWORK

TITLE = Motor Start Control

// Start Logic

Motor_Run := Motor_Run OR Start_Button;

// Stop Logic

Motor_Run := Motor_Run AND NOT Stop_Button;

END_FUNCTION_BLOCK

Safety Design: Preventing Issues Before They Arise

In industrial control, safety is always the top priority. Siemens PLC provides various safety functions, and we must learn to utilize them effectively.

-

Hardware Interlocking: Use the PLC’s input and output points to implement hardware interlocking for key equipment to prevent misoperations.

-

Software Protection: Incorporate various checks and protective measures in the program, such as limit alarms and fault diagnostics.

-

Fail-Safe Design: When designing the program, consider various potential failure scenarios to ensure the system can safely shut down in case of issues.

-

Access Control: Use the PLC’s password protection features to set different levels of operation permissions, preventing unauthorized modifications.

Note: Safety functions should be regularly tested to ensure they work properly in critical moments.

Human-Machine Interface Design: Making Operations More Intuitive

A good Human-Machine Interface (HMI) can significantly enhance operational efficiency and safety. Siemens’ WinCC software provides powerful HMI design tools.

-

Interface Layout: Keep it simple and clear; important information should be prominent, and frequently used functions should be easily accessible.

-

Alarm System: Design clear alarm displays and handling processes to help operators quickly locate and resolve issues.

-

Data Visualization: Use graphical methods like trend charts and bar graphs to present key data, making the system’s operational status clear at a glance.

-

Operation Guidance: For complex operational processes, design a wizard-like interface to reduce human errors.

Practical Tips: When designing HMI, communicate with actual operators to understand their needs and habits.

Debugging and Optimization: Striving for Excellence

After writing the program, the work is not finished. Debugging and optimization are key steps to enhance system performance.

-

Simulation Testing: Use Siemens’ PLCSIM software for offline simulation, allowing you to test program logic without connecting to actual hardware.

-

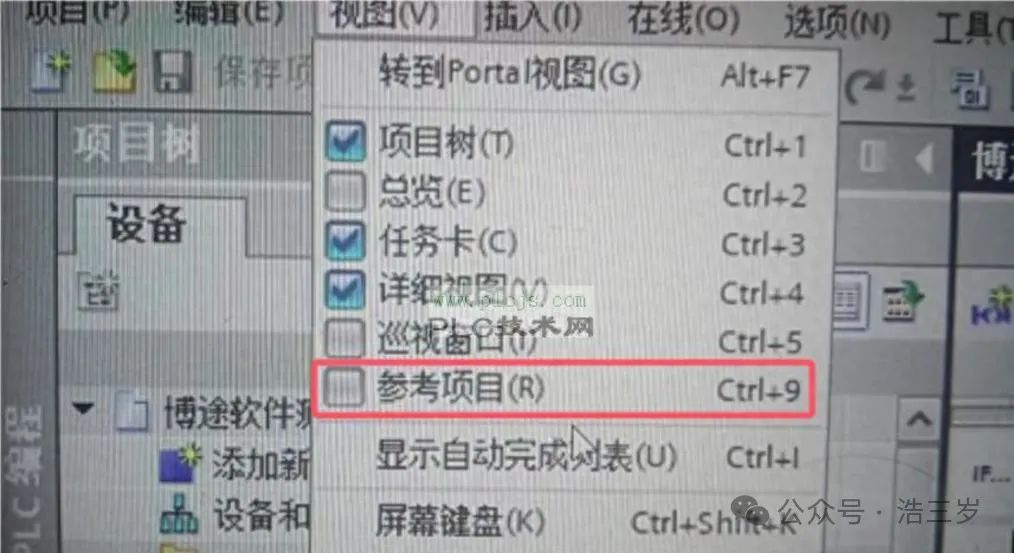

Online Monitoring: Use online monitoring functions to observe the program’s running status in real-time, identifying potential issues.

-

Performance Optimization: Analyze the PLC’s scan cycle, optimizing program structure and algorithms to improve system response speed.

-

Data Logging: Use the data logging feature to collect system operation data, providing a basis for future optimization.

Debugging Tips: When encountering complex issues, you can use the “divide and conquer” method, which involves splitting the system in half to gradually narrow down the problem scope.

Document Management: Paving the Way for the Future

Good documentation not only facilitates oneself but also serves future users.

-

Program Comments: In addition to comments within the code, also write an overall program description document.

-

Wiring Diagrams: Carefully document the PLC’s input and output wiring, including terminal numbers, wire colors, etc.

-

User Manual: Write a concise user manual covering common operational processes such as starting, stopping, and troubleshooting.

-

Version Control: Use version control tools to manage different versions of the program for easy tracking of modification history.

Experience Sharing: I once encountered an old factory’s equipment that was difficult to maintain due to a lack of documentation. Since then, I have developed the habit of detailed recording, which not only helps myself but also makes team collaboration smoother.

Practical Suggestions

-

Start with simple control tasks and gradually challenge more complex projects.

-

Pay attention to Siemens’ official technical forums and documentation, where there are many practical tips and solutions.

-

Try to participate in some open-source PLC projects to learn different programming ideas and best practices.

-

Regularly review and summarize your project experiences to build your own knowledge base.

-

Maintain a passion for learning; PLC technology is constantly evolving, and we must keep pace with the times.

Through the above steps, I believe everyone can become proficient in using Siemens PLC to optimize industrial control systems. Remember, theory and practice must be combined; engage in hands-on work and thoughtful reflection to truly master this technology.

Reposting is a form of motivation; sharing is a virtue.

Take a moment to click 【Looking】 before you go.