> Imagine this: At 3 AM in a beverage factory, the filling machines stand tall like swans, precisely injecting liquid into every bottle; robotic arms tighten caps with millimeter precision, as if performing a mechanical ballet; conveyor belts transform into a flowing dance floor, carrying bottled drinks to the packaging area—this seamless “dance” is orchestrated by a small iron box: PLC (Programmable Logic Controller). It may not have a glamorous stage, but it enables cold steel to perform a precise dance!

Sensory Nerves—The Factory’s “Peripheral Touch” Providing Real-Time Feedback

Photoelectric Sensors: Like sharp eyes, capturing the moment a bottle passes (`Signal:1`)

Pressure Transmitters: Like sensitive fingertips, sensing pressure fluctuations in the pipeline (`Signal:0.8MPa`)

Temperature Probes: Like precise thermometers, monitoring subtle changes in fermentation tanks (`Signal:37.5℃`)

Emergency Stop Buttons: Like pain receptors, issuing the highest alarm in case of danger (`Signal:0→1Emergency Disconnect`)

> PLC‘s “Sensory Collection”: Scanning hundreds of sensor signals every millisecond, converting the physical world into0/1 digital streams, akin to how the brain receives neural impulses.

Decision-Making Center—The “Choreography Logic” in the Program Operating at High Speed

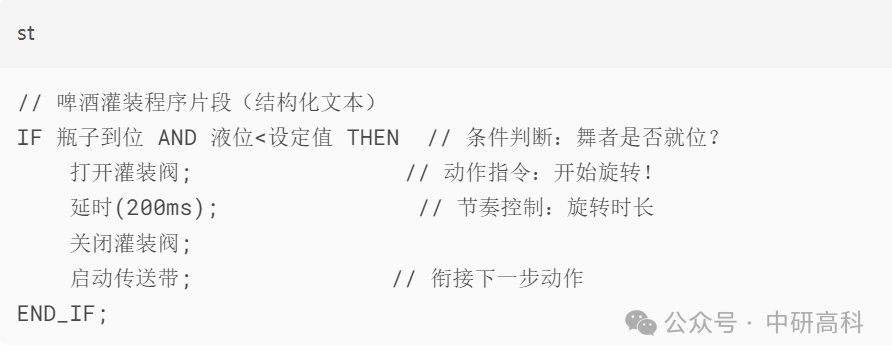

PLC‘s internal program executes line by line like a musical score

Sequential Control: Strictly following the choreography process of “StartA→CompleteB→TriggerC“

Conditional Judgments: Such as the safety rule of “If temperature>100℃ then stop heating”

Timing/Counting: Precisely controlling the lifting duration of robotic arms and the number of packages

> PLC‘s “Cognitive Decision-Making”: Looping through the program at millisecond speed, converting input signals into output instructions, like the brain interpreting sensory information and issuing action commands.

Physical Response—The “Muscle Memory” of Actuators Landing Precisely

PLC output signals trigger motors, cylinders, and other actions

Output Signals→ Relays: Powering the motor, starting the conveyor belt

Analog Output→ Control Valves: Regulating the opening of steam valves (`Output:4-20mA → Opening50%`)

High-Speed Pulses→ Servo Drives: Directing robotic arms to trace perfect trajectories (`Pulses = Position, Frequency = Speed`)

> PLC‘s “Action Execution”: Converting logical decisions into current signals, driving actuators to complete physical actions, just as the brain commands muscle contractions.

Continuous Dance—The Never-Ending “Scanning Waltz”

PLC scanning cycles repeat like clock gears

1. Input Scan (1ms): Reading all sensor statuses (“Dancer position confirmed!”)

2. Program Execution (5ms): Running user-defined control logic (“Choreographing the next move!”)

3. Output Refresh (1ms): Updating actuator control signals (“All execute the new dance step!”)

4. Communication Self-Check (2ms): Exchanging data with HMI screens and robots (“Coordinating stage lights!”)

> Key Secret: PLC cycles through this process at a speed of 100~1000 times/second, ensuring immediate response to emergencies (like a bottle falling) in the next cycle, achieving “zero-delay synchronization” in the dance!

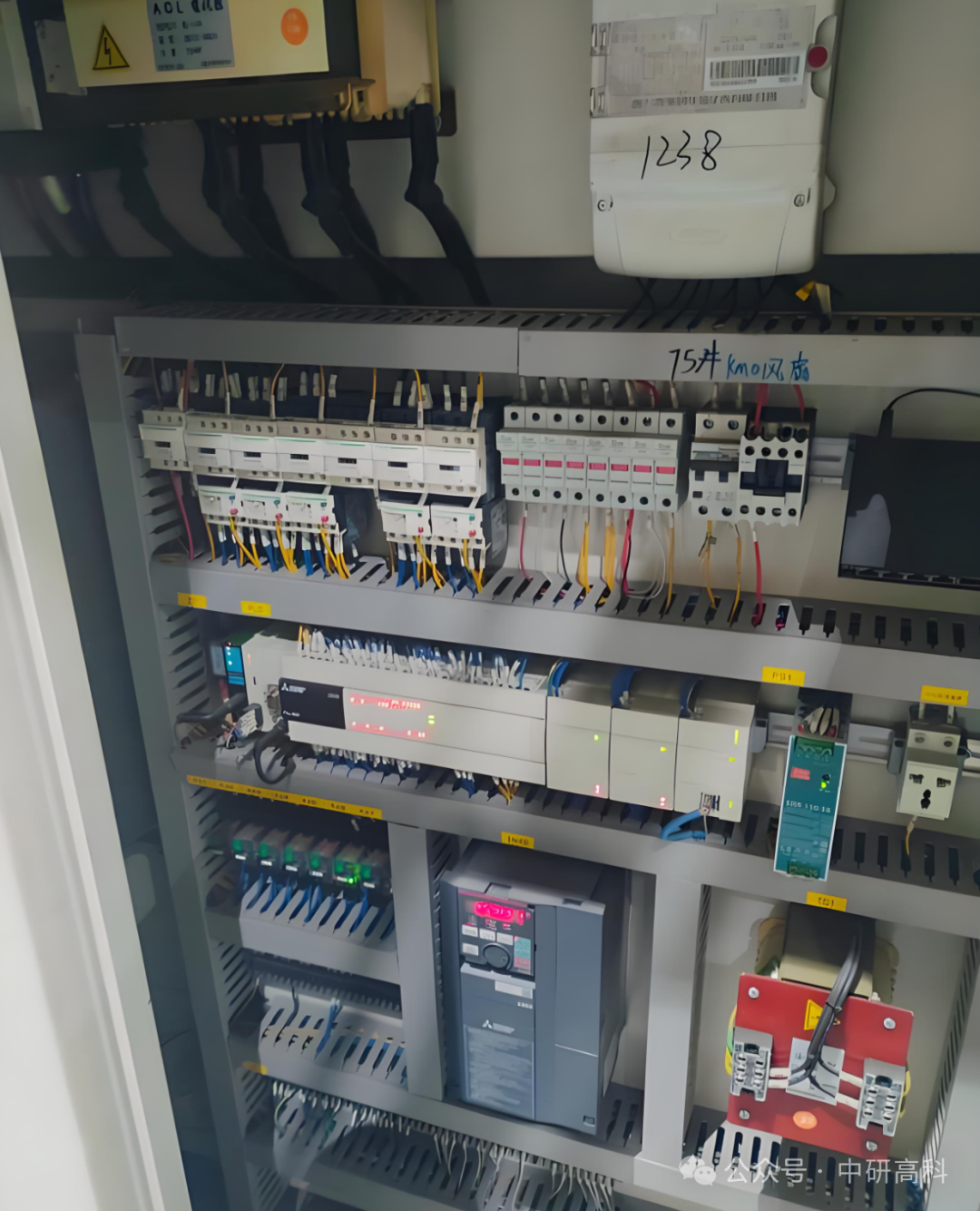

Collaborative Symphony—The “Group Dance Conducting” of Multiple PLCs

Multiple PLCs exchange data through industrial networks

PROFINET/EtherCAT networks: Gigabit fiber transmitting control commands (`Latency<1ms`)

Master PLC: Coordinating the rhythm of the filling line and packaging line (“Accelerate the chorus section!”)

Slave PLC: Controlling robotic arms to complete complex grabs (“Complete the lifting action!”)

HMI touch screens: Displaying the “dance” status in real-time, supporting manual intervention

> Collaborative Intelligence: In modern factories, dozens of PLCs form a “symphony orchestra” through industrial networks, with the master station acting like a conductor waving data streams, allowing the production line to perform a synchronized group dance.

Why is the PLC the “Ultimate Brain” of Factory Dance?

1. Reliability: Fanless, fully sealed design, resistant to dust, vibration, and electromagnetic interference (-25℃~70℃ normal operation)

2. Determinism: Strictly timed scanning cycles (error<0.01%), eliminating “missteps” in the dance

3. Flexibility: Programs can be rewritten at any time, producing cola today and switching to juice tomorrow (“Instantly change choreography!”)

4. Diagnostic Capability: Real-time monitoring of equipment status, predicting motor lifespan (“Dancer stamina warning!”)

> Industrial Truth: PLC doesn’t actually “think”, but it executes error-free cycles thousands of times per second, showcasing the beauty of deterministic industrial processes to the fullest—this is the precise dance gene written by humans for machines.

Conclusion: When Steel Begins to Dance

Next time you see robotic arms on the production line tracing elegant arcs, remember: it is the PLC conducting an industrial ballet that never takes a bow. It uses the rhythm of 0 and 1 to create precise beats, allowing gears to mesh perfectly and hydraulic cylinders to extend with the beauty of strength. In the spark-flying welding workshop and the dust-free room of sterile filling, this silent “industrial brain” is weaving the epic dance history of modern manufacturing at the speed of light—without spotlights, yet it is the most stunning stage of the intelligent era.