The chip is a pinnacle of human technology, embodying vast amounts of wisdom. The chip supply chain is extremely complex; spending a hundred million may buy a luxury apartment, but it may not necessarily support a chip from design to mass production. This is especially true for chips that use advanced processes, where the costs can be staggering. For example, the design cost of a 5nm chip can reach as high as $476 million.

Given that chips are so “money-hungry,” how many steps are required to go from nothing to a fully functional chip?

Chip Design

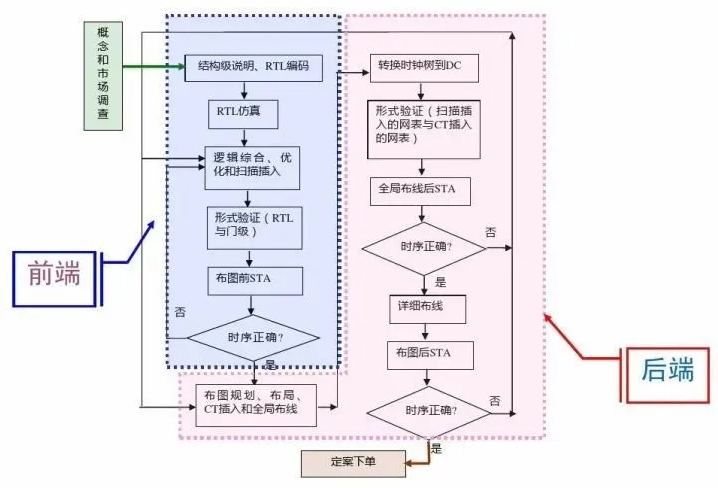

Chip design can be divided into two parts: front-end design and back-end design. The overall process is illustrated in the following diagram:

Front-End Design

Front-end design can be divided into the following six steps:

RTL Design

Verification

Static Timing Analysis

Coverage

ASIC Logic Synthesis

The front-end design process is not completed in one go; engineers must repeatedly synthesize, verify, and conduct various design rule checks to ensure both the correctness of the design and the feasibility and optimization of the layout and routing.

Back-End Design

Back-end design mainly consists of the following six steps:

Logic Synthesis

Formal Verification

Physical Implementation

Clock Tree Synthesis – CTS

Parasitic Parameter Extraction

Layout Physical Verification

Back-end design is the implementation of front-end design. Specifically, it involves converting the logic synthesis into a physical netlist, which is then transformed into graphic files that can be used by manufacturing plants to create photomasks.

Chip Manufacturing

It is understood that a chip production line involves approximately 2000-5000 processes. Broadly speaking, wafer production includes two major steps: ingot manufacturing and wafer fabrication, along with wafer probe testing, collectively referred to as the front-end processes of wafer manufacturing.

Chip Manufacturing Process

1. Purification

Sand/quartz is deoxidized and purified to obtain silica with a silicon content of 25%. This is then refined in an electric arc furnace, treated with hydrochloric acid, and distilled to achieve crystal silicon with a purity of over 99%.

2. Ingot Manufacturing

Crystal silicon is melted at high temperatures and drawn using a rotating method, undergoing neck growth, crown growth, crystal growth, and tail growth to form a complete ingot.

3. Slicing

The ingot is sliced horizontally using a circular saw with diamond particles embedded in the inner diameter edge, cutting it into wafers of approximately uniform thickness.

4. Polishing

The wafers are polished to remove saw marks and damage from cutting, achieving the required surface smoothness.

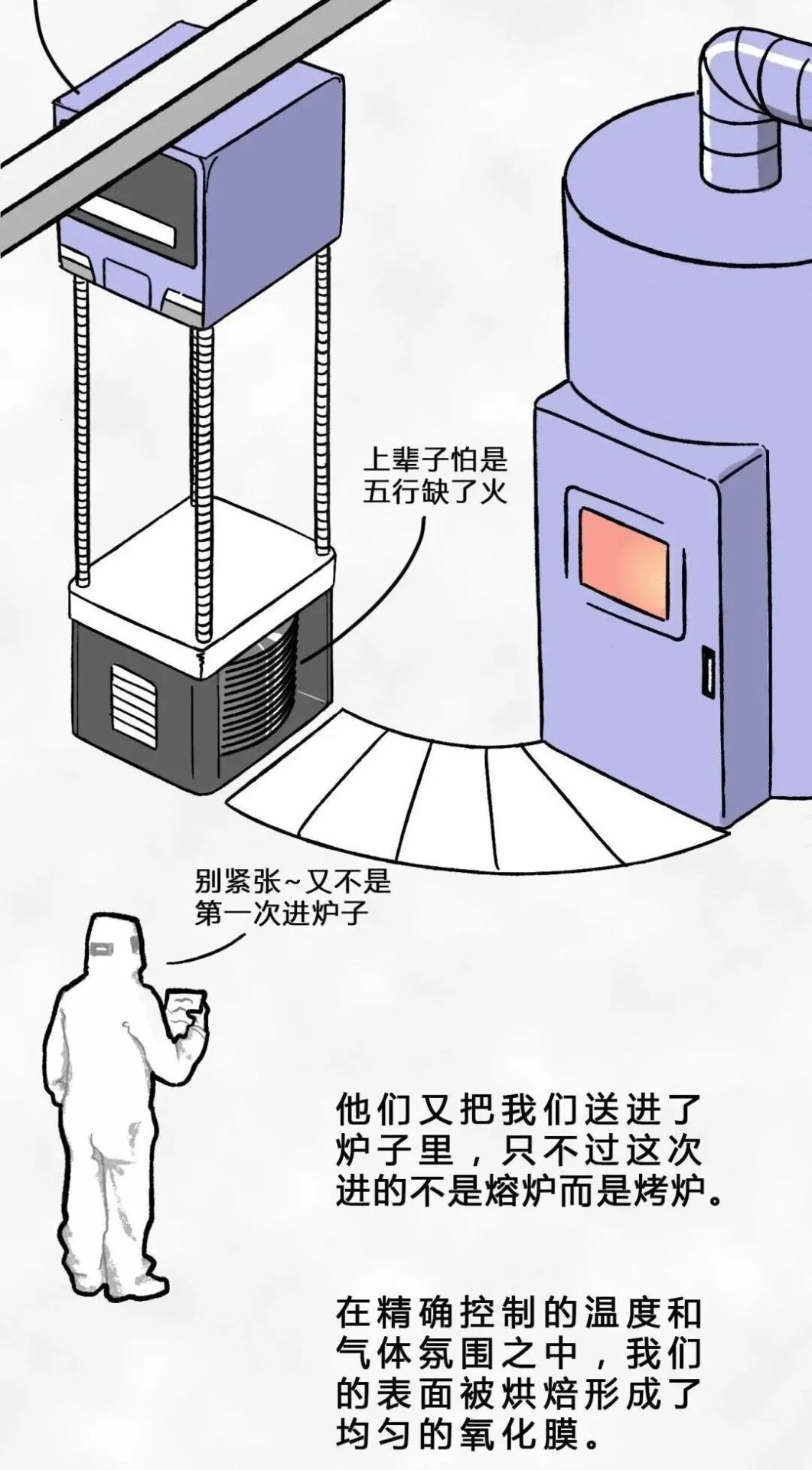

5. Oxidation

The surface undergoes oxidation and chemical vapor deposition, which serves as an auxiliary layer for later processes and helps isolate electrical components to prevent short circuits.

6. Photolithography and Etching

A layer of photoresist is coated and dried on the wafer (or substrate), which is then transferred to a photolithography machine. Through a mask, light projects the pattern onto the photoresist on the wafer surface, achieving exposure and chemical luminescence reactions.After exposure, the wafer undergoes a second baking, known as post-exposure bake.

Finally, a developer is sprayed onto the photoresist to form the exposed pattern. After development, the pattern on the mask is retained on the photoresist.

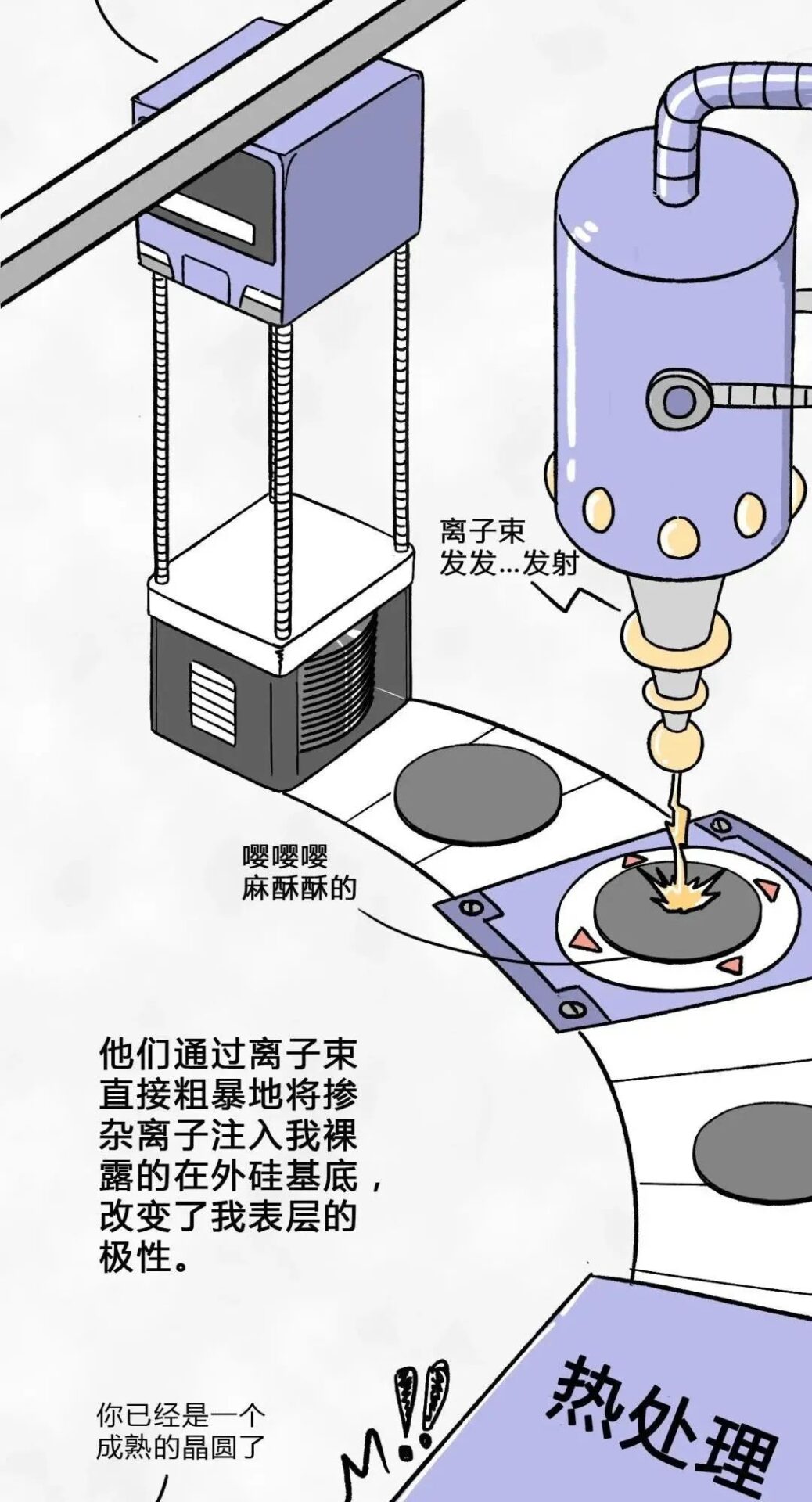

7. Ion Implantation and Annealing

Before removing the remaining photoresist, positive or negative ions can bombard the wafer, implanting impurity ions into the semiconductor lattice. Then, the ion-implanted semiconductor is heated at a certain temperature to activate different electrical properties of the semiconductor material.

8. Chemical Vapor Deposition and Electroplating

Chemical vapor deposition is used to form various metal layers and insulating layers, while electroplating is specifically used for growing copper interconnect layers.

9. Chemical Mechanical Polishing

Combining chemical etching and mechanical polishing for finishing.

10. Finally, multiple layers of circuits and components are processed and fabricated on the wafer.

11. Wafer Probe Testing: Each die is tested for its electrical characteristics using a probe tester, discarding any defective dies.

Chip Packaging and Testing

Packaging and testing involve the process of packaging the tested wafers into chips and testing for defective chips, including pre-packaging wafer testing and finished product testing.

As the last mile before chip production, packaging and testing are also crucial steps for finished chips. Packaging protects, supports, connects, and dissipates heat from the chip, while testing ensures chip quality and can even enhance shipping quality, preventing defective chips from being released.

Specifically, the packaging and testing steps can be divided into:

1. Backside Thinning: Thinning the backside of the wafer to achieve the required thickness for packaging.

2. Wafer Cutting: Cutting the wafer into individual dice, followed by cleaning the dice.

3. Optical Inspection: Checking for defective products.

4. Chip Bonding

5. Silver Paste Curing

6. Wire Bonding

7. Molding: To prevent external shocks, the product is encapsulated with EMC (molding material) and simultaneously heated to cure.

8. Laser Marking: Marking the product with production dates, batches, and other information.

9. High-Temperature Curing: Protecting the internal structure of the IC and eliminating internal stress.

10. Excess Material Removal: Trimming the edges.

11. Electroplating: Enhancing conductivity and improving solderability.

12. Final Forming and Inspection of Defective Products.

13. Chip Testing: The chips that have reached their final form must undergo final defect testing. Only finished semiconductor chips enter the final testing phase. They will be placed in testing equipment set to various conditions such as voltage, temperature, and humidity for electrical, functional, and speed testing. The results of these tests can be used to identify defects, improve product quality, and enhance production efficiency.

14. Products that pass testing are labeled with specifications, models, and production dates before being packaged for shipment.

Of course, the steps involved in semiconductor manufacturing are far more than these, and chip manufacturing is indeed a capital-intensive industry. To achieve true mass production of a chip, each of the steps mentioned above is crucial. Each chip undergoes hundreds of refinements before becoming a part of an electronic device, transforming from “sand” into a “chip”; semiconductor technology truly performs a modern-day version of turning stone into gold.

*Image Disclaimer: The images in this article are sourced from the internet. If there are any infringements or objections, please contact us to have them removed.