The control methods of robots can be categorized into various types based on the control variables and control algorithms. Below, we will introduce commonly used robot control methods for different types.

1. Classification Based on Control Variables

According to the different spaces of control variables, robot control can be divided into joint space control and Cartesian space control. For serial multi-joint robots, joint space control targets the variables of each joint, while Cartesian space control targets the variables of the robot’s end effector. Based on the different control variables, robot control can be classified into: position control, velocity control, acceleration control, force control, and hybrid force-position control. These controls can be either joint space control or end effector Cartesian space control.

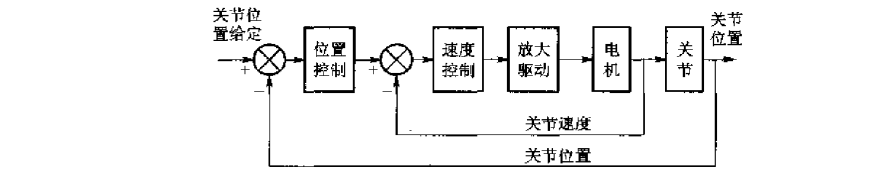

The goal of position control is to make the controlled robot’s joints or end effector reach the desired position. Taking joint space position control as an example, the error obtained by comparing the given joint position with the current value serves as the input for the position controller. After processing by the position controller, its output becomes the set value for joint velocity control. Joint position controllers commonly use PID algorithms, but fuzzy control algorithms can also be employed.

Figure 1-1 Schematic of Joint Position Control

In Figure 1-1, removing the position outer loop results in the control block diagram for the robot’s joint velocity control. Typically, in target tracking tasks, robot velocity control is employed. Furthermore, the basic principles for position and velocity control in the end effector’s Cartesian space are similar to those in joint space.

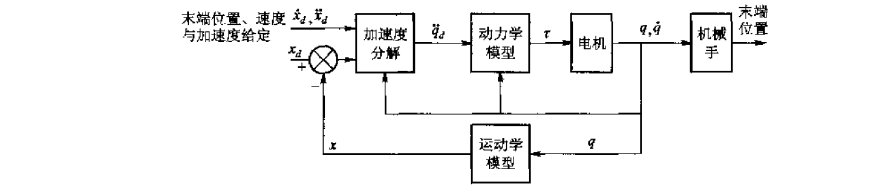

Figure 1-2 Schematic of Acceleration Control

Figure 1-2 illustrates the schematic of decomposed acceleration motion control. First, the control acceleration of the end effector is calculated. Then, based on the desired values of position, velocity, and acceleration of the end effector, as well as the current end effector position, joint position, and velocity, the corresponding acceleration for each joint is decomposed. The control torque is then calculated using the dynamics equations, requiring torque control for each joint.

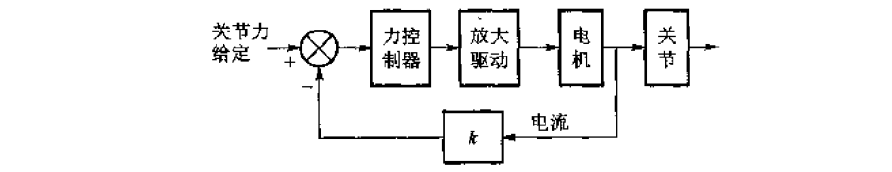

Figure 1-3 Schematic of Joint Force/Torque Control

Figure 1-3 shows the block diagram for joint force/torque control. Since joint force/torque is difficult to measure directly, the current of the joint motor can effectively reflect the torque of the joint motor. Therefore, the current of the joint motor is often used as the measurement value for the current joint force/torque. The force controller adjusts the joint motor based on the deviation between the desired and measured force/torque.

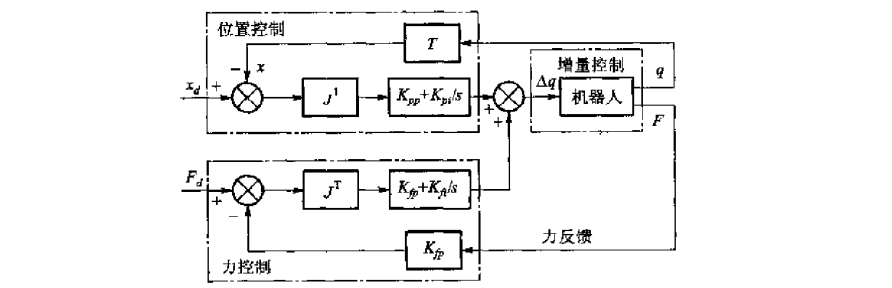

Figure 1-4 Block Diagram of Hybrid Force-Position Control

Figure 1-4 illustrates a block diagram of hybrid force-position control, which consists of position control and force control. Position control is PI control, with the setpoint being the Cartesian space position of the robot’s end effector. The feedback of the end effector’s Cartesian space position is obtained from the joint space position through kinematic calculations. In the figure, T represents the robot’s kinematic model, and J is the Jacobian matrix of the robot. The difference between the desired and current end effector position is converted into joint space position increments using the inverse of the Jacobian matrix, and after PI computation, it becomes part of the joint position increment.

Force control is also PI control, with the setpoint being the Cartesian space force/torque of the robot’s end effector, and feedback is obtained from force/torque sensors. The difference between the desired and current end effector force/torque is converted into joint space force/torque using the transpose of the Jacobian matrix. The joint space force/torque undergoes PI computation to become another part of the joint position increment. The outputs of the position control and force control parts are summed to form the expected value of the joint position increment. The robot uses incremental control to manage the position of each joint. The hybrid force-position control shown in Figure 1-5 is just a simple scheme within hybrid force-position control, a simplified form of R-C (Raibert-Craig) hybrid force-position control, which should be adjusted as necessary for specific environments in practical applications.

2. Classification Based on Control Algorithms

Based on different control algorithms, robot control methods can be classified into PID control, variable structure control, adaptive control, fuzzy control, and neural network control, among others. Some literature also categorizes existing control algorithms into logical threshold control, PID control, sliding mode variable structure control, neural network control, and fuzzy control. These control methods are not isolated; they are often used in combination within a control system.

1. PID Control

In practical engineering, the most widely used regulation control law is proportional, integral, and derivative control, abbreviated as PID control, also known as PID regulation. The PID controller has been in existence for nearly 70 years, and its simple structure, good stability, reliability, and ease of adjustment have made it one of the main technologies in industrial control. When the structure and parameters of the controlled object cannot be fully grasped, or when an accurate mathematical model cannot be obtained, and other control techniques are difficult to apply, the structure and parameters of the system controller must be determined based on experience and on-site debugging, making PID control technology the most convenient option.

That is, when we do not fully understand a system and the controlled object, or cannot obtain system parameters through effective measurement methods, PID control technology is the most suitable. PID control can also be implemented as PI and PD control. The PID controller calculates the control quantity based on the system’s error using proportional, integral, and derivative calculations.

2. Variable Structure Control

Variable structure control is a control scheme developed in the 1950s in the Soviet Union. Variable structure control refers to a control system that has multiple controllers, which are used under different conditions according to certain rules. The use of variable structure control has many advantages that other controls do not possess, allowing for the control of a class of nonlinear systems with uncertain parameters.

3. Adaptive Control

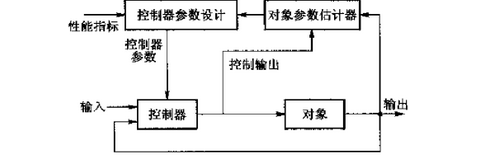

Adaptive control refers to a system that can self-adjust its parameters or control strategies when the input or disturbances undergo significant changes, ensuring that the output still meets design requirements. Its basic structure is shown in Figure 2-1. Adaptive control deals with systems characterized by “uncertainty” and aims to reduce this uncertainty through observation of random variable states and system model identification. The control results often achieve certain control indicators, where “optimal control” is replaced by “effective control.”

Adaptive control systems can be classified into model reference adaptive control systems, self-correcting control systems, self-optimizing control systems, variable structure control systems, and intelligent adaptive control systems, among others. Among these types, model reference adaptive control systems and self-correcting control systems are more mature and commonly used.

Figure 2-1 Basic Structure of Self-Correcting Control System

4. Fuzzy Control

In fuzzy control, the input is fuzzily quantified into fuzzy variables, and fuzzy outputs are obtained through reasoning based on fuzzy rules, which are then defuzzified to obtain clear output values for control. Fuzzy control was first proposed by Professor Zadeh from the University of California in 1965, and in 1974, E.H. Mamdani from the UK successfully applied fuzzy control to boiler and steam engine control. Since then, fuzzy control has rapidly developed in the control field and has achieved numerous successful applications.

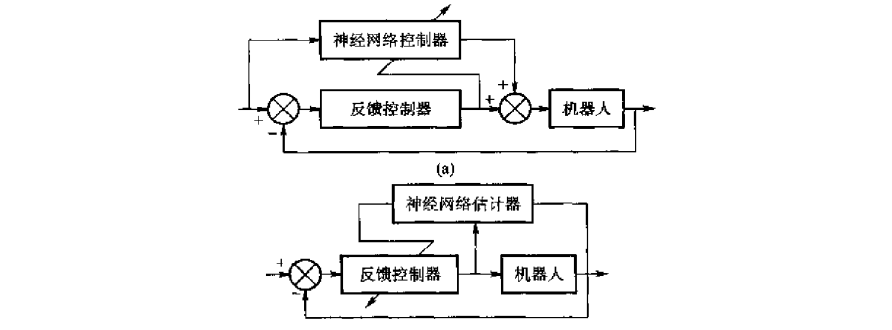

5. Neural Network Control

Neural network control is one of the cutting-edge disciplines in automatic control that developed in the late 1980s. It is a new branch of intelligent control that opens up new avenues for solving control problems in complex, nonlinear, uncertain, and indeterminate systems. Neural network control is a product of the combination of (artificial) neural network theory and control theory, and it is an evolving discipline. It integrates theories, technologies, methods, and research results from various fields, including mathematics, biology, neurophysiology, brain science, genetics, artificial intelligence, computer science, and automatic control, as shown in Figure 2-2.

In the control field, control systems with learning capabilities are referred to as learning control systems, which belong to intelligent control systems. Neural control is capable of learning and is a branch of learning control, which is part of intelligent control. Despite its relatively short history of just over a decade, neural control has already developed various control structures, such as neural predictive control and neural inverse system control.

Figure 2-2 Structure of Neural Network Control System

▶ Source: Industrial Robots, Compiled by: Lang Li Tao Xiang

▶ The editor thinks you might also like these: :

:

Stamping Automation Production Line: This speed, this efficiency….

[Includes multiple video cases] Application of Industrial Robots in the Automation of Light Alloy Gravity Casting

100% Welding Automation Production Line, Eye-Opening

Introduction to the Main Components of Industrial Robots

[Video] ABB Robot Solutions in the 3C Application Industry

Scan the QR code to add the editor as a friend

Feel free to tell me what you do (other greetings are ineffective; the editor really can’t reply to hundreds of smiley faces every day!), after “registration,” I will add you to our professional technical exchange group to meet more industry experts and big names!

Feel free to tell me what you do (other greetings are ineffective; the editor really can’t reply to hundreds of smiley faces every day!), after “registration,” I will add you to our professional technical exchange group to meet more industry experts and big names!