Automotive safety systems must be able to handle all malicious attacks that occur without warning during the system lifecycle. In this regard, designing high-quality security protections for automotive SoC systems is particularly important. The most robust approach is to integrate a hardware security module (HSM) within the SoC chip.

Omar Cruz

ARC Processor IP Product Marketing Manager

Synopsys is the first company to launch an ASIL D dual-core lockstep processor and safety manager architecture. Under the requirements of the automotive quality management system process, we fully considered hardware random faults, AEC Q100 reliability testing, etc., when developing IP. The ASIL D compliant DesignWare® ARC® SEM130FS safety and protection processor IP can help designers protect safety-critical systems from software, hardware, and side-channel attacks while also offering high performance and low power consumption advantages.

It is understood that the DesignWare® ARC® and EV processors have been optimized to provide the best PPA (Performance/Power/Area) for embedded SoCs, allowing designers to optimize the performance, power, and area of each processor instance on their SoC by implementing only the required hardware.

At the same time, the DesignWare ARC SEM130FS processor and DesignWare ARC functional safety processor not only provide the processor IP itself but also offer SoC developers an ASIL-D certified compiler and a comprehensive set of functional safety documentation, greatly simplifying the SoC certification process:

-

Quality manual of the Synopsys IP Business Unit’s Quality Management System (QMS)

-

Design Failure Mode and Effects Analysis (DFMEA), focusing on avoiding potential system failures

-

Failure Modes, Effects, and Diagnostic Analysis (FMEDA) focusing on assessing random hardware failure (including permanent and transient failure) metrics

-

Safety manual, describing applicable scenarios, internal and external safety mechanisms, and assumptions of use

-

Related Failure Analysis (DFA), covering common failures and cascading failures (if applicable)

-

Safety case report, indicating the evidence reference that Synopsys will use internally for review and evaluation

-

ISO 26262 assessment report covering ASIL B random hardware failures and ASIL D systematic failures

In addition, the ARC SEM130FS safety and protection processor simplifies the development of safety-critical applications and accelerates the ISO 26262 certification of automotive SoCs by providing ASIL-D compliant solutions and all necessary hooks and safety mechanisms required in automotive environments. This includes the following key features:

-

Pre-validated dual-core lockstep processor: Security implementation based on low-power SEM safety processor

-

Safety monitor: Provides monitoring to ensure that the main core and shadow core remain in lockstep operation

-

Error detection and correction logic (ECC): Handles data and address errors on tightly coupled memory

-

Integrated watchdog timer: Enables countermeasures to help recover from deadlock situations

In simple terms, chip manufacturers only need to adopt the DesignWare ARC SEM130FS processor and the DesignWare ARC functional safety processor to quickly complete the functional safety certification of automotive SoC products.

Undeniably, under the broader context of automotive electrification, intelligence, and connectivity, the electronic and electrical architecture of the entire vehicle is evolving from distributed to centralized architectures. Consequently, the risks arising from electronic and electrical failures are increasing, and functional safety is receiving more attention.

For instance, in the automotive chip field, in addition to the AEC-Q reliability testing standards for automotive electronic components, meeting the stringent functional safety standards of ISO 26262 ASIL certification has become the entry rule for automotive supply chain manufacturers.

“Safety and reliability are the core elements that are inseparable in future vehicles,” Omar Cruz stated. As the key brain of automotive-grade SoC systems, the safety manager monitors and manages system faults and real-time failures within the SoC system, helping chip manufacturers meet ASIL-D level functional safety certification.

Synopsys’s DesignWare IP solutions can be used for in-vehicle infotainment systems, advanced driver assistance systems (ADAS), gateways, and mainstream microcontrollers (MCUs), ensuring high quality and reliability for automotive applications.

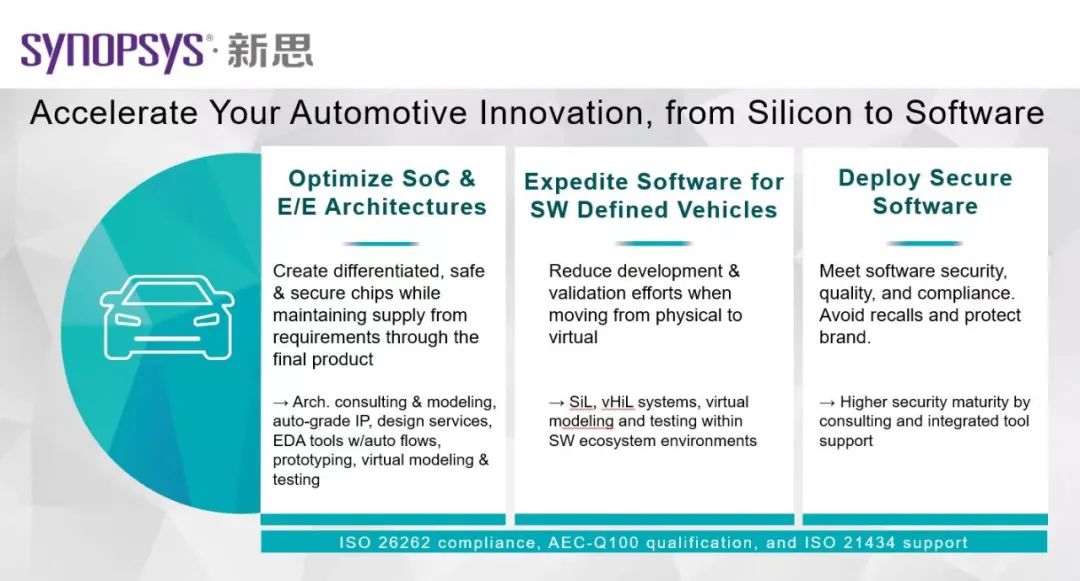

It is worth noting that Synopsys’s complete set of solutions can provide the driving force for all innovations in the digital age.Among these, Synopsys primarily provides three core advantages in the development of the entire automotive industry, accelerating automotive innovation comprehensively.

For example, by optimizing SoC and E/E architectures, it helps developers create differentiated safety SoC chips throughout all stages from early design requirements to final product launch, thereby ensuring that software-defined vehicles reduce potential design errors during development and verification, accelerating mass production.

At the same time, deploying safety software on vehicles, while meeting the complex automotive quality system requirements, continuously adapts to changes in software safety for automotive applications, avoiding future safety recalls and effectively protecting brands.

In the future, intelligent connected vehicles, especially those with autonomous driving capabilities, will continuously upgrade their automotive data security, network security, software upgrades, functional safety, and expected functional safety management.

From chip IP, automotive-grade SoC design implementation and verification to the deployment of automotive electronic and electrical architecture and intelligent connected vehicle safety software, Synopsys can provide complete information security protection for vehicle safety and innovative solutions. The competitive advantages in the future automotive market are already very apparent.