Master Zhang has been scratching his head lately!

In his factory, the precision weighing equipment has not exceeded the sensor’s calibration value during weighing, yet the sensor has “failed” three times in just one month. After replacing the sensor, it malfunctioned again in a few days, and the repair costs have added up to several thousand, making the boss increasingly displeased.

Master Zhang has checked everything repeatedly but cannot find the cause. Could it really be that the sensor quality is too poor?

It wasn’t until he invited an expert to diagnose the issue that the truth came to light — the real culprit was not “overloading,” but rather the instantaneous shock that everyone overlooked! This seemingly insignificant “invisible killer” is quietly consuming your equipment’s lifespan and hard-earned money!

Today, we will not only uncover the truth but also share a magic tool that can extend the lifespan of sensors!

For those in engineering and equipment management, have you ever wondered: the sensor is rated for 100 kg, but it breaks when I load 110 kg? Everyone thinks it’s due to overloading, but this “overloading” is wrongly blamed! Generally, sensors have a safety margin of 150%; as long as you don’t consistently push the limits and occasionally reduce the load, it shouldn’t “fail.”

The real reason for the sensor’s “instant failure” is — instantaneous shock!

This thing is like the “assassin” in the sensor world, hard to guard against! For example, a 10 kg box dropped from a height of 10 cm seems harmless, but according to physics formulas, it can generate an instantaneous impact of 1000 Newtons (about 100 kg of force)! This is equivalent to hitting the sensor with a hammer; the internal strain gauges and elastic elements can’t withstand it and will crack on the spot!

Even worse, instantaneous shocks can also play “hidden tricks.” Sudden stops of forklifts and vibrations during equipment startup seem trivial, but they act like “chronic poison.” Repeated minor shocks can cause internal components of the sensor to “secretly fracture,” with cracks appearing today and broken wires tomorrow. By the time you notice the measurement accuracy has collapsed, it has already reached a critical state, and you can only replace it!

How high is the cost of replacing a sensor?

The procurement cost alone is a significant expense, not to mention the production delays and penalties for overdue orders… The total loss could be dozens of times the price of the sensor!

Don’t panic!

Today, I will share four practical protection tips to help you tackle instantaneous shocks at the source and extend the sensor’s “lifespan” by several years!

1. Standard Operating Procedures: Don’t be a reckless “strongman”

Many instantaneous shocks are caused by improper operations! For instance, throwing goods onto the weighing platform or abruptly stopping a forklift can seem convenient at the moment, but they are actually “torturing” the sensor. The correct approach is:

-

Handle with care: When transporting goods, try to lower and move them gently, avoiding free-fall placements;

-

Slow down: When forklifts or cranes approach the sensor area, slow down in advance, and brake gently to prevent inertia from becoming an accomplice to the shock;

-

Install guiding devices: Set up buffer slides and positioning barriers in the loading and unloading areas to ensure goods “land steadily,” reducing collision impact.

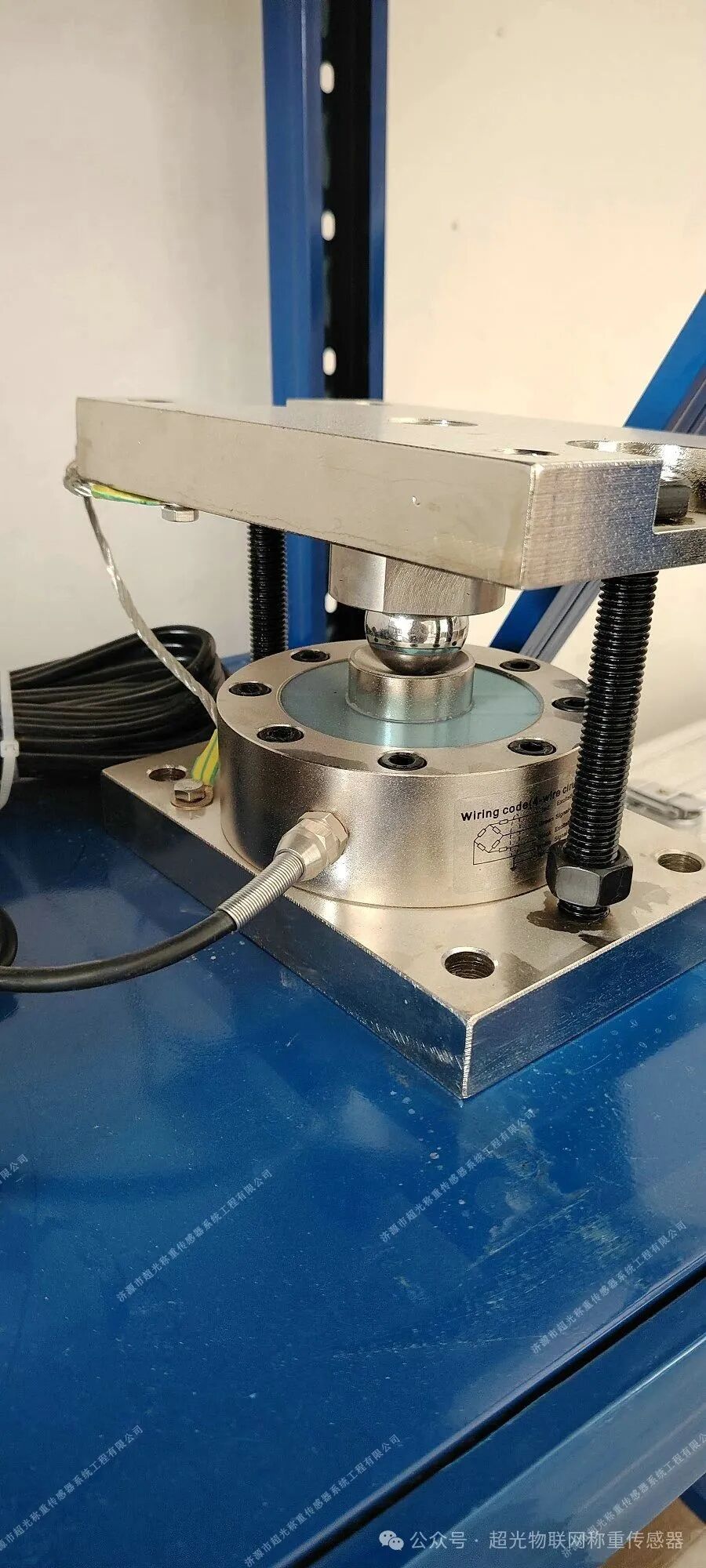

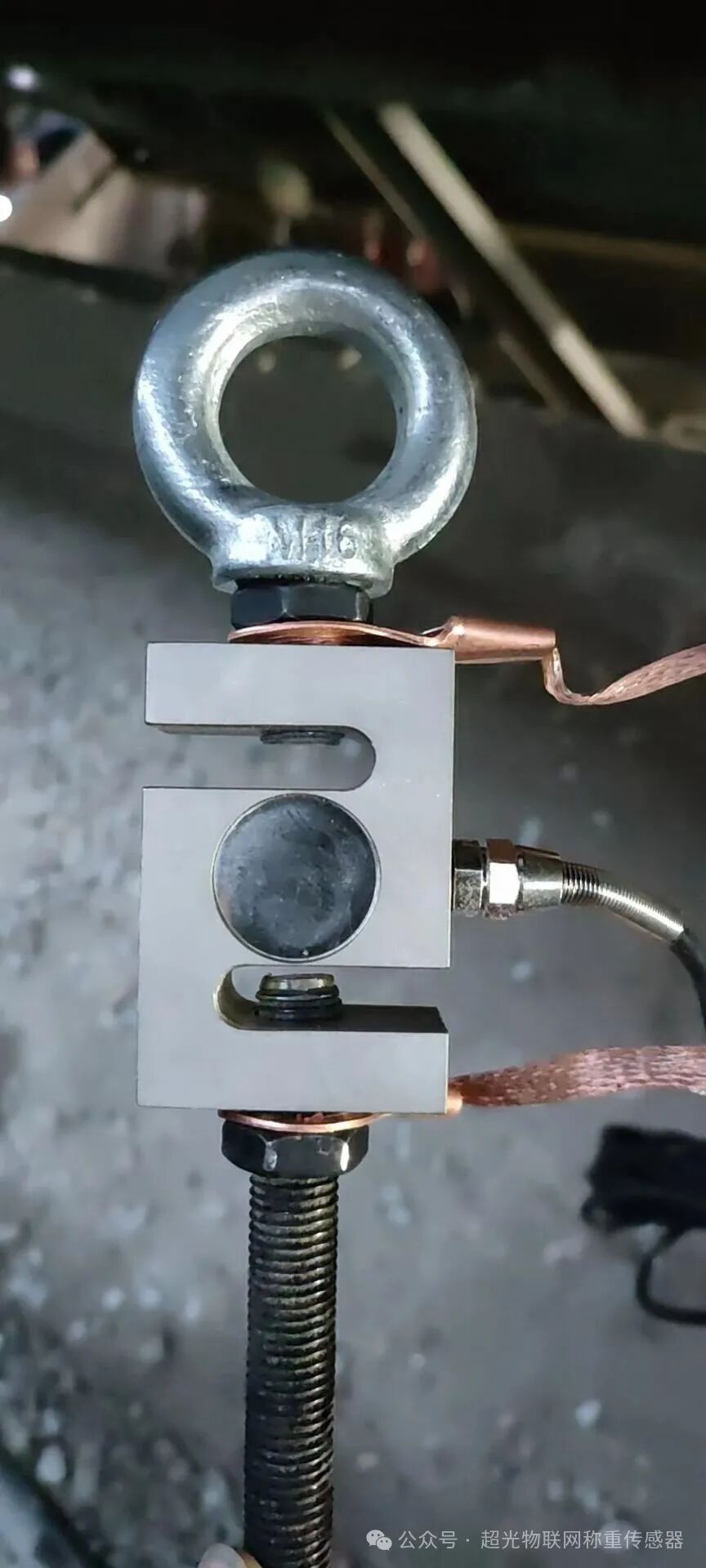

2. Installation Details: Build a “safe foundation” for the sensor

If the sensor is installed correctly, it can have its own “shock-absorbing buff”! Remember these three key points:

-

Choose the right installation location: Keep it away from large motors, stamping equipment, and other strong vibration sources, like finding a quiet “paradise” for the sensor;

-

Add cushioning pads: Place elastic materials like rubber or silicone between the sensor and the mounting base, like putting “shock-absorbing shoes” on it; when impact occurs, the cushion absorbs most of the force;

-

Reinforce the support structure: Ensure that the sensor’s mounting bracket and base are stable, with screws tightened to prevent it from “wobbling,” reducing additional shocks caused by resonance.

3. Regular Maintenance: Conduct periodic “check-ups” to prevent minor issues from escalating

The damage caused by instantaneous shocks often accumulates over time. Paying more attention to inspections can save a lot on repair costs:

The damage caused by instantaneous shocks often accumulates over time. Paying more attention to inspections can save a lot on repair costs:

-

High-frequency equipment checks: For sensors on equipment like assembly lines or high-frequency vibrating screens, check at least once a week for loose screws or deformed casings;

-

Monitor abnormal data: If the sensor’s measurement values suddenly fluctuate or show abnormal peaks, don’t ignore it; it could mean internal components have been “injured” by shocks, so stop the machine and investigate immediately;

-

Regular cleaning and maintenance: Timely clean dust and oil from the sensor’s surface to prevent these small particles from exacerbating wear during impacts.

4. Technological Upgrades: Equip your devices with an “intelligent shield”

Technology changes fate! If the budget allows, consider trying these “black technologies”:

-

Intelligent shock-absorbing systems: Install shock-absorbing devices with automatic adjustment functions that can adaptively adjust the cushioning strength based on the impact force, effectively giving the sensor a “smart bodyguard”;

-

Impact monitoring and warning: Install impact monitoring sensors on critical equipment; once abnormal shock forces are detected, they immediately trigger alarms and even automatically shut down the system, preventing damage at the source.

By implementing these strategies, even the most cunning instantaneous shocks will have to “surrender”!

What exclusive tips do you have for shock protection? Feel free to share in the comments, and let’s learn from each other! If you find this useful, don’t forget to like and share it, so more peers can avoid pitfalls!