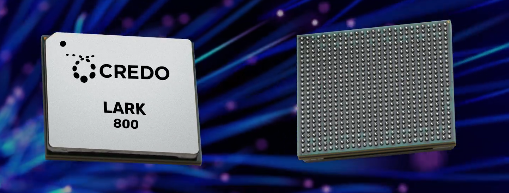

The report from Electronic Enthusiasts Network (by Liang Haobin) states that as optical modules develop towards 800G and 1.6T high speeds, DSP is facing increasing challenges, including performance and power consumption. Due to the small size of optical modules and the difficulty in heat dissipation, the power consumption of high-performance DSPs determines whether stable operation can be maintained in the working environment of data centers.Therefore, we see that optical module DSPs have begun to adopt advanced processes. For example, Marvell launched the industry’s first 3nm process PAM4 optical DSP chip, Ara, last December, built on Marvell’s sixth-generation technology in the PAM4 optical DSP field. It can integrate eight 200 Gbps electrical channels and eight 200 Gbps optical channels, achieving a transmission rate of 1.6 Tbps in a compact standardized module.Thanks to the 3nm process, Ara reduces the power consumption of the 1.6 Tbps optical module by more than 20%. Recently, Credo also released the Lark series DSP for 800G optical modules, which includes two innovative optical DSP products.Lark 800 is a high-performance, high-reliability, low-power DSP designed for the next generation of fully clock retimed 800G optical modules, suitable for the harsh power consumption and heat dissipation environments of the world’s largest and densest AI data centers.Lark 850 is specifically designed for 800G linear receive optical module (LRO) applications, achieving module power consumption below 10 watts.Both Lark series DSPs adopt Credo’s fifth-generation DSP architecture, effectively addressing the most severe optical signal distortion issues. In terms of reliability, both DSPs are designed to achieve robust performance in harsh environments, with Lark 800 innovatively integrating link monitoring functionality to monitor the connection status of Ethernet links.An important feature of the Lark series is its low power consumption, focusing on minimizing energy usage. The Lark series features programmable energy-saving modes, setting a new benchmark for 800G energy efficiency.The energy consumption of data centers has been a frequently discussed issue in the industry during the rapid development of AI in recent years. The scale of data center construction continues to expand, and the power of computing chips is increasing, leading to a surge in data center energy consumption.The energy consumption of data centers mainly comes from several parts, including various devices in the core server cabinets; precision air conditioning systems that provide constant temperature and humidity for the server room; cooling fans on server boards; and even water cooling systems; as well as power distribution systems, such as transformers, uninterruptible power supplies (UPS), and distribution cabinets, which also consume energy during power conversion and distribution.Reducing data center energy consumption can be achieved by adopting the latest computing chips with higher energy efficiency, effectively lowering energy consumption while providing the same computing power; or by using third-generation semiconductor power solutions to improve power conversion efficiency and reduce losses. The power consumption of optical modules, as a key component in data center data transmission, cannot be ignored.Dr. Scott Wilkinson, Chief Analyst at Cignal AI, pointed out that as AI drives data center scales to unprecedented levels, the power consumption issue is becoming increasingly critical. For every watt of power consumed by optical interconnects, it means one watt less for GPUs. Over 9 million 800GbE modules are expected to be deployed by 2024, with projections exceeding 14 million by 2025 (source: Cignal AI Q3 2024 Optical Component Report). Credo’s Lark DSP can reduce the power consumption of optical modules for internal interconnects in data centers, playing a key role in addressing energy issues in data centers.This is also the reason why DSPs in optical modules are beginning to adopt 5nm and even 3nm processes. As optical modules evolve from 800G to 1.6T and 3.2T, lower power consumption DSPs will play a greater role in energy-saving efforts in data centers.

Recently, Credo also released the Lark series DSP for 800G optical modules, which includes two innovative optical DSP products.Lark 800 is a high-performance, high-reliability, low-power DSP designed for the next generation of fully clock retimed 800G optical modules, suitable for the harsh power consumption and heat dissipation environments of the world’s largest and densest AI data centers.Lark 850 is specifically designed for 800G linear receive optical module (LRO) applications, achieving module power consumption below 10 watts.Both Lark series DSPs adopt Credo’s fifth-generation DSP architecture, effectively addressing the most severe optical signal distortion issues. In terms of reliability, both DSPs are designed to achieve robust performance in harsh environments, with Lark 800 innovatively integrating link monitoring functionality to monitor the connection status of Ethernet links.An important feature of the Lark series is its low power consumption, focusing on minimizing energy usage. The Lark series features programmable energy-saving modes, setting a new benchmark for 800G energy efficiency.The energy consumption of data centers has been a frequently discussed issue in the industry during the rapid development of AI in recent years. The scale of data center construction continues to expand, and the power of computing chips is increasing, leading to a surge in data center energy consumption.The energy consumption of data centers mainly comes from several parts, including various devices in the core server cabinets; precision air conditioning systems that provide constant temperature and humidity for the server room; cooling fans on server boards; and even water cooling systems; as well as power distribution systems, such as transformers, uninterruptible power supplies (UPS), and distribution cabinets, which also consume energy during power conversion and distribution.Reducing data center energy consumption can be achieved by adopting the latest computing chips with higher energy efficiency, effectively lowering energy consumption while providing the same computing power; or by using third-generation semiconductor power solutions to improve power conversion efficiency and reduce losses. The power consumption of optical modules, as a key component in data center data transmission, cannot be ignored.Dr. Scott Wilkinson, Chief Analyst at Cignal AI, pointed out that as AI drives data center scales to unprecedented levels, the power consumption issue is becoming increasingly critical. For every watt of power consumed by optical interconnects, it means one watt less for GPUs. Over 9 million 800GbE modules are expected to be deployed by 2024, with projections exceeding 14 million by 2025 (source: Cignal AI Q3 2024 Optical Component Report). Credo’s Lark DSP can reduce the power consumption of optical modules for internal interconnects in data centers, playing a key role in addressing energy issues in data centers.This is also the reason why DSPs in optical modules are beginning to adopt 5nm and even 3nm processes. As optical modules evolve from 800G to 1.6T and 3.2T, lower power consumption DSPs will play a greater role in energy-saving efforts in data centers.

Disclaimer: This article is original from Electronic Enthusiasts. Please indicate the source when reprinting. For group discussions, please add WeChat elecfans999, for submission inquiries, please email [email protected].

More Hot Articles to Read

-

Electronic Skin Breaks Out, Igniting Humanoid Robots

-

The World’s First Two-Dimensional RISC-V MPU! Named “Wuji”, from the Fudan Team

-

Revolution in Humanoid Robot Perception! Innovative Machine Vision Sensors Emerge

-

Entering the Thousand Yuan Level! Exoskeleton Robots Sold Out, These Motor Companies Accelerate Positioning

-

Global Foundries and UMC Plan Merger! Challenging Samsung, the Global Wafer Foundry Landscape May Change

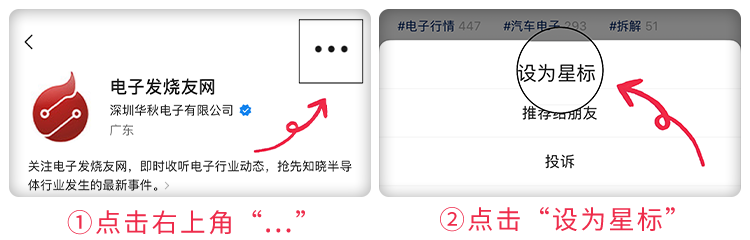

Click to Follow and Bookmark Us

Bookmark us to not miss any updates!